S.S. (Stainless Steel) Filter Housing / SS Filter Vessels

The stainless-steel (S.S.) filter housing from Zonel Filtech is designed for liquid and gas/steam filtering applications for various industries, these S.S. filter housings can be used for both primary filtration and high-purity filtrate handling with different micron-rated filter bags or filter cartridges.

The stainless-steel filter housing can be produced with SS 304 and SS316L, which are widely used for food & medical grade liquid or gas/steam filtration even other corrosive chemical and high-temperature materials filtration. The inner and outer surfaces of the SS filter housing can be treated with sandblasting or polishing as requested to make the filters have excellent filtration performance.

All of the SS filter housings from Zonel Filtech are produced strictly according to the standard of GB150.1~150.4-2011, which will be tested thoroughly before the delivery, including raw material testing, high-pressure testing, corrosion testing, and so on.

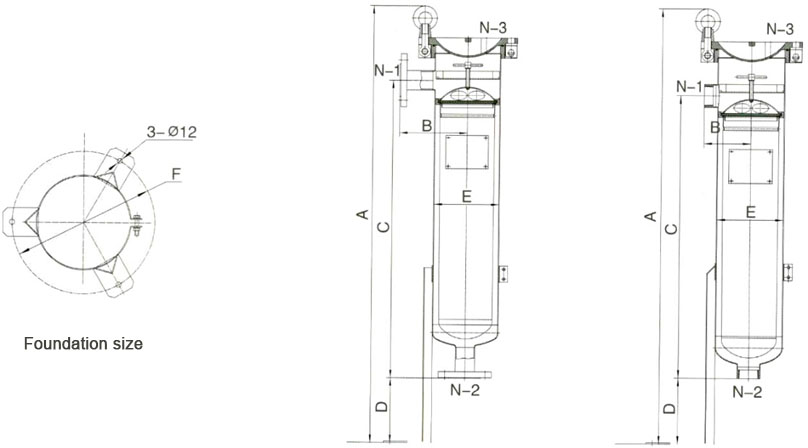

SS bag filter housing – single bag side entrance

General introduction:

The side entrance stainless steel bag filter housing with the construction of side inlet and bottom outlet, that design makes the SS filter housing very easy to wash; optimized design on micron rated filter bag fixing and sealing, woven SS drained basket, screw tight SS bag filter housing cap makes the liquid filter bags with a perfect performance even under the high pressure.

Properties:

a. The SS (stainless steel) bag liquid filter housing with side inlet and removable cap, the solution won’t spill over when opening the filter housing.

b. The Liquid filter housings with screw tight, no need for special tools to operate them.

c. This SS single bag filter housing with a stable and adjustable supporting shelf, is easy to install.

d. The SS bag filter housing with the optimized sealing solution, without leakage under high pressure.

e. The Stainless steel filter housing with sound polishing treatment and SS supporting cage, well protects the micron-rated liquid filter bags and is easy to wash.

f. The SS304 filter housing and SS316 filter housing both can be chosen.

Design available:

Qty of the filter bag(suitable for both traditional and absolute micron-rated filter bags): Single

Bag size: No.1, 2, 4, and so on, special sizes can be customized.

Connection size of the SS bag filter housing: DIN/ANSI/BSP/NPT

Material of the liquid filter vessels: SS304 filter housing, SS316 Filter Housings, and special material can be customized.

Sealing ring of the Liquid filter housings: Buna N/EPDM/Viton/Silicon/ FEP+FPM

Application environments of the Stainless Steel bag Filter Housing:

Max. flow of the SS bag filter housing: 40 CBM/hr

(note: testing filter house size: No.2, the actual flow will be subject to the filter media and the properties of the solutions as well)

The design operation temperature of the stainless steel filter housing: 150 degrees C.

Designed pressure of the liquid filter housing: 10 Bar.

Applicable industries of stainless Steel bag Filter Housings:

a. Painting

b. Electronic industries

c. Electrolyte

d. Silica industries

e. Fine chemicals

f. Paper production

g. Food industries

The typical parameters of the side-in SS single-bag industrial filter housings:

Size | Bag No.2, mm (inch) | Bag No.1, mm(inch) |

A | Flange: 1350 (53) Thread: 1310 (52) | Flange: 986 (40) Thread: 950 (37) |

B | Flange: 210 (8) Thread: 142 (6) | |

C | Flange: 920 (36) Thread: 880 (35) | Flange: 556 (22) Thread: 530 (21) |

D | 200 (8) adjustable | |

E | 200 (8) | |

F | 321 (13) | |

Parameters | Bag No.2, mm (inch) | Bag No.1, mm(inch) |

In/outlet (N1/N2) | Flange: DN50 PN16RF (2” 150#RF)/ Thread: DN50 (2” BSP) | |

Air emission(N3) | 1/2” FNPT | |

Designed press. | 10 bar (145PSI) | |

Designed temp. | 150-degree C (which subject to the filter media and sealing material as well) | |

Volume of filter | 28 L (7 Gal) | 17 L (4 Gal) |

Net weight | 28 kg (62 lb) | 24 kg (53 lb) |

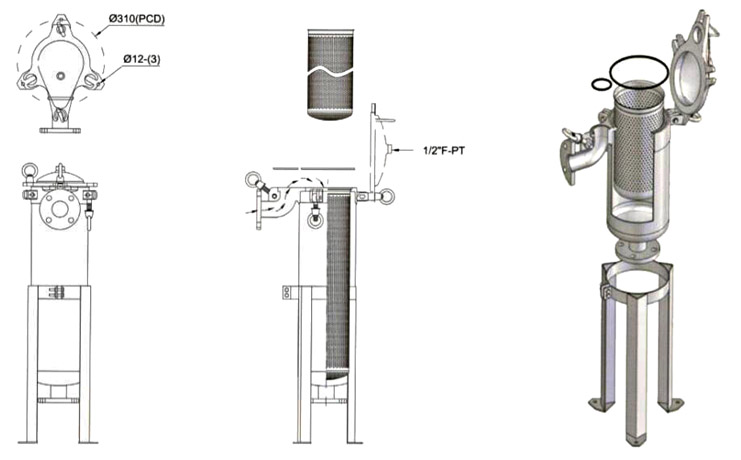

SS bag filter housing – single bag Top entrance

General introduction of the stainless steel bag filter housing:

The top-entrance SS bag filter house with the construction of top inlet and bottom outlet that makes the filtration not effect by turbulent flow; optimized design on liquid filter bag fixing and sealing, screw tight filter house cap makes the micron rated liquid filter bag with a perfect performance even under the high pressure.

The properties of the liquid filter housings (many as stainless steel water filter housing for many industries):

a. The SS filter housing with top inlet, not effect by turbulent flow, make the micron rated liquid filter bags with the perfect filtration efficiency and service life.

b. The SS filter housing with stable and adjustable supporting shelf, easy installing.

c. The SS liquid filter housing with compact structure and smooth flow pipe, small resistance effect.

d. The SS bag filter housing with optimized sealing solution, without leakage under high pressure.

e. The SS filter housing with screw tight design, no need special tools with operating.

f. The industrial filter housing with sound polishing treated filter house and supporting cage, well protect the filter bags and easy washing.

Design available for the industrial Filter Housing:

Qty of the filter bag: single

Bag size: No.1, 2, 4 and so on, the special size can be customized.

Connection size: DIN/ANSI/BSP/NPT

Material of the liquid filter vessels: SS316 filter housing, SS304 Filter Housings, special material can be customzied.

Sealing ring: Buna N/EPDM/Viton/Silicon/ FEP+FPM

Application environments of SS bag filter housing:

Max. flow: 40 CBM/hr

(note: testing filter house size: No.2, the actual flow will subject to the filter media and the properties of the solutions as well)

Design operation temperature: 150-degree C.

Designed pressure: 10 Bar.

Applications of the stainless steel filter housing:

a. Painting

b. Electronic industries

c. Electrolyte

d. Silica industries

e. Fine chemicals

f. Paper production

g. Food industries

The typical parameters:

For more information, please feel free to contact Zonel Filtech!

S.S. multi-Bag Filter Housing

General introduction and properties of the stainless steel multi-bag filter housing:

The SS multi-bag filter housing is always adopted as the liquid filter housing or water filter housing for many industrial applications: The SS multi-bag filter house is rotary type open design, easy to operate;

The SS filter housing with its compact design, a small size, reduces the solution loss;

The SS bag filter housing with the optimized outlet design, completely unloading;

The SS liquid filter housing with the perfect sealing solution so as to get the 0 leakage.

Design available for stainless steel multi-bag filter housing:

Qty of the liquid filter bag: multi-bag.

Bag size for the SS filter housing: No.1,2 and so on, the special size can be customized.

Connection size of the SS bag filter housing: DIN

Material available for the SS filter housing: 316L stainless steel filter housing, 304 Stainless Steel Filter Housings, special material can be customized.

Sealing ring: Buna N/EPDM/Viton/Silicon/ FEP+FPM

Applications of the stainless steel multi-bag filter housing:

a. Painting

b. Electronic industries

c. Electrolyte

d. Oil and gas

e. Fine chemicals

f. Paper production

g. Food industries

h. Metallurgy

The typical parameters of the stainless steel bag filter housing:

Filter bag qty | Max. Flow (CBM/hr) |

3 | 120 |

4 | 160 |

6 | 240 |

8 | 320 |

12 | 480 |

17 | 680 |

23 | 920 |

25 | 1000 |

70 | 2000 |

Parameters | 1 bag | 3 bag | 6 bag | 12 bag | 17 bag | 23 bag |

In/outlet | DN50 | DN80 | DN150 | DN200 | DN250 | DN250 |

Air outlet | DN15 | |||||

Press. Meter connection | DN15 | |||||

Unload connection | DN15 | |||||

Designed pressure | 10-16 Bar | |||||

Designed temperature | As arrange | |||||

Filter housing volume | 28L | 180L | 274L | 750L | 995L | 1336L |

Weight | 28kg | 155kg | 210kg | 620kg | 880kg | 1000kg |

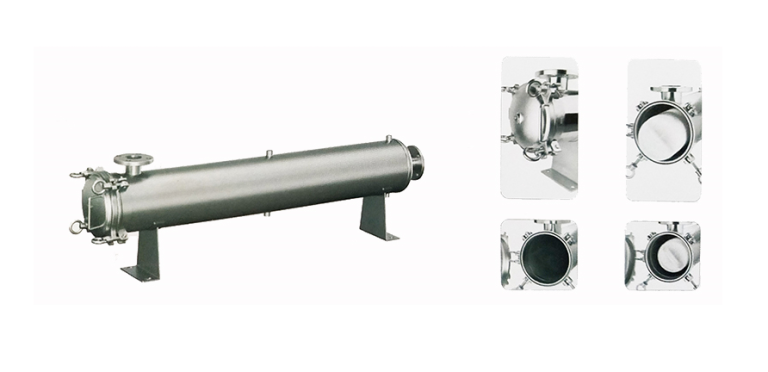

SS Cartridge Filter Housing

General introduction and properties of the Cartridge Stainless Steel Filter Housing:

The SS cartridge filter housing from Zonel Filtech mostly comes with a multi-cartridge designed SS filter housing, which is combined with stainless steel vessel and liquid filter cartridges or air/steam filter cartridges, the solution/airflow direction is from outside to the inner side of the filter cartridges, the filtrate flow out from the inner core of the filter cartridges and the solid particles will be blocked at surface of the filter cartridges.

The cartridge stainless steel filter housing (mainly offering includes 304 stainless steel cartridge filter housing and 316L stainless steel cartridge filter housing) is always put at downstream of the pressure filter machines to help filter the fine particles out from the liquid/gas.

Design available for Cartridge Stainless Steel Filter Housing:

The SS Cartridge filter housing can be divided into single-cartridge filter housing and Multi-cartridge filter housing.

Filter cartridge’s size for the SS cartridge filter housing can be 10~40”

Connection size: DIN/ANSI/BSP/NPT

Material of the SS filter housing: 304/316L, the special materials can be customized.

Sealing ring of the SS filter housing: Buna N/EPDM/Viton/Silicon/ FEP+FPM

Application environments for Cartridge SS Filter Housing:

Max. flow: 1 CBM/hr

(note: testing filter cartridge size: 20”, the actual flow will be subject to the filter media and the properties of the solutions as well)

Design operation temperature: 150 degrees C.

Designed pressure: 10 Bar.

Applicable industries for SS cartridge Filter Housing:

a. Painting

b. Electronic industries

c. Electrolyte

d. Silica industries

e. Fine chemicals

f. Paper production

g. Food/beverage industries

i. pharmaceutical industries

Relevant technical parameters of the cartridge SS filter housing for reference:

Parameters | 12 cartridges | 20 cartridges | 90 cartridges | 130 cartridges |

In/outlet | DN50 | DN80 | DN150 | DN150 |

Air outlet | DN15 | |||

Press. Meter connection | DN15 | |||

Unload connection | DN15 | |||

Designed pressure | 10-16 Bar | |||

Designed temperature | As arrange | |||

Filter housing volume | 125L | 180L | 900L | 1250L |

Weight | 120kg | 130kg | 600kg | 780kg |

High flow cartridge filter housing-HFC series

General introduction and properties of the high-flow cartridge filter housing:

HFC series high-flow cartridge filter housing adopted the high-flow filter cartridges instead of the traditional PP melt-blown filter cartridge, the flow volume per single cartridge can be up to 50 CBM per hour.

Generally, 1 pcs of 40inches high flow filter cartridges is equal to 20 pcs of melt-blown PP filter cartridges with the same length, which means the filter housing can be designed smaller, and much more convenient for maintenance work, also can get a much more economical filtration solution of course.

Design available for high-flow cartridge filter housing:

Cartridge qty: 1~50 pcs

Filter cartridge size: 20~60”

Filter housing material: SS 304 / SS 316

Sealing ring: EPDM / Viton / Silicone / FEP+FPM / Buna N

Application environment for high-flow cartridge filter housing:

Maximum testing flow volume: 20 CBM/hour @ 20” filter cartridge.

Design temperature: 150 degrees C.

Design pressure: 10 bar.

Applicable industries for high-flow cartridge filter housing:

a. Painting

b. Electronic industries

c. Electrolyte

d. Silica industries

e. Fine chemicals

f. Paper production

g. Food/beverage industries

i. pharmaceutical industries

Relevant products:

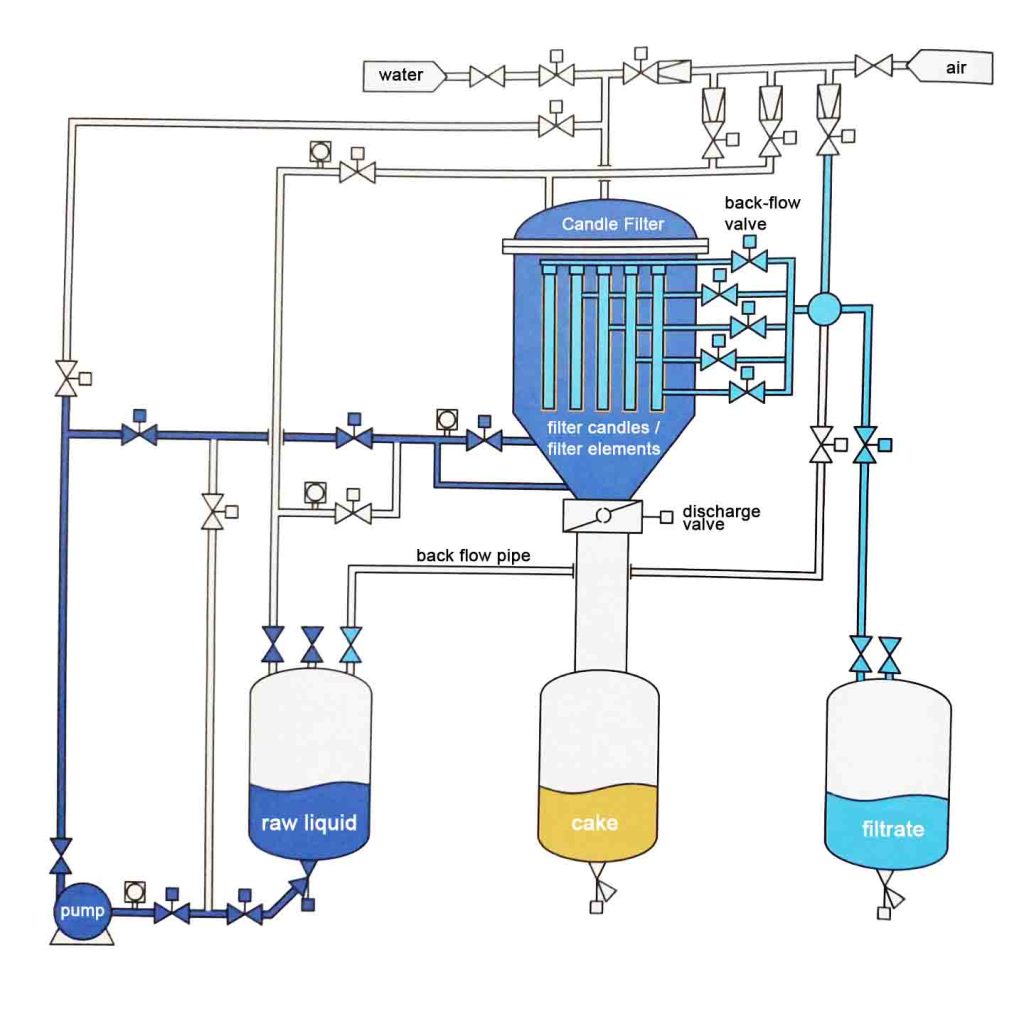

Liquid filter cartridges Complete system of candle filter cake layer filter

Candle Filters

The properties of the candle filter from Zonel Filtech:

a. The candle filters from Zonel FIltech with a big flow volume, can filter directly, or be coated first with cake filtration to improve the filter efficiency, widely used for cake recycling, and liquid concentrating applications, and the cake can be washed before recycling them, with a much higher purity.

b. The candle filter was PLC controlled, the filter procedures like the solution feeding, prefiltration, filtering, raffinate draining, reverse blow cake release, cake discharge, and so on will be arranged automatically.

c. Suitable for high precision, high solid particle content, and sticky solution filtration.

d. The filter element/ filter candle distance is adjustable according to the cake thickness requested.

e. The filter housing of the candle filter is highly sealed and suitable for corrosive or some dangerous solution treatment.

f. The candle filter With an optimistic drying design, can meet various moisture content requirements from different clients.

g. The candle filter is static design, easy to maintain

Technical parameters of the candle filter:

Design pressure: 0.6MPa, 1.0MPa, 1.6MPa, 2.0MPa (super higher pressure can be customized)

Filter element: seamless textile filter tube, SS mesh tube, metal sintered filter cartridge, etc.

Design operating temperature: 0~300 degrees C.

Flow volume design: 10~300 m3/hr

Filter area: 0.9~60 m2 (more filter area can be customized)

Filter housing diameter: 250~2500 mm

Reverse blowing air pressure: 0.2~0.3MPa

Controlling system: PLC, DCS

In/outlet size: 2~24”

The material of the machine touches with the solutions: SS 304/SS316L, 904L, others can be customized according to requirements.

Inner side coating for anti-corrosive can be: PP, PE, F30, F40, F46, PFA

Sealing material: NBR, VITON, Silicon rubber, etc.

Draining valves: soft sealing or hard sealing butterfly valves.

Optional instruments can be chosen: pressure gauge/pressure transmitter, cake thickness sensor, liquid level sensor, flow volume transmitter, etc.

Applications of the candle filter:

Mainly used for liquid filtration in the industries of chemical industries, food and beverage industries, machinery processing, pharmaceutical industries, etc.