Home » Products

Products

Categories

Zonel Filtech developed the para-aramid filter cloth (Kevlar filter fabric) / filter bags for candle filters which widely used for Raney Nickel collection in reactor for BDO production (ethyne method, as the BDO reactor filter bag or BDO catalyst filter bag) process, etc.

The BDO production process is that acetylene and formaldehyde pass through the catalyst (Raney nickel catalyst) slurry layer in countercurrent, and react at 93°C, 0.1 MPa with the catalyst. The stirrer and the acetylene gas entering from the lower part of the reactor can keep the catalyst in suspension.

The phenolic resin filter cartridge which adopted the phenolic fiber blended with cohesive, hardener, stabilizer, and so on then sintered into the filter cartridges, to improve the strength of the phenolic fiber, which can blended with polyamide (5~10%) when production.

The phenolic resin filter cartridge from Zonel Filtech has a fiber bonded outer to inner with gradually tighter construction, which makes them with a bigger particle loading capacity, good strength, and durability.

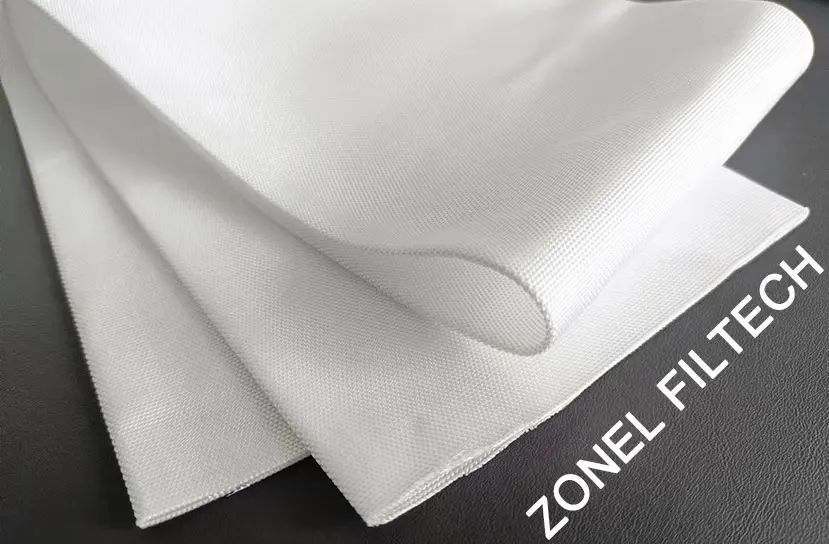

Zonel Filtech provide super quality polyester air slide fabrics for air slide systems / pneumatic conveyor systems and the homogenization silo, etc.

The polyester air slide belt from Zonel Filtech can be divided into polyester spun yarn air slide canvas, polyester filament air slide membrane and polyester nonwoven air slide cloth for different usages and requirements from the clients.

The filament polyester air slide fabric with a smooth surface and equal air permeability, strong construction, excellent for abrasion resistance, durable; the spun yarn polyester air slide belt with the same construction as the filament air side membrane, also offered widely for air slide solutions and mixing the powdered/granular in homogenization silo, with the competitive price; the nonwoven air slide belt, with the needle punched nonwoven construction (nonwoven polyester air slide cloth), easy installing, the width can be customized within 3.5 meters.

The Polyester (PET, terylene felt) needle felt nonwoven filter cloth with the properties of high tensile strength, super abrasion resistance, good acid resistance, and food grade, one of the most economical filter materials that is widely used in various industrial applications for dust collection usage (dust filter cloth for dust filter bags production).

Zonel Filtech with the most experienced and skillful team, owns the modern needle punching lines combined with first-grade raw materials to make the polyester needle felt filter cloth from Zonel with equal air permeability and thickness, high tensile strength, smooth surface and easy release the dust cake, durable.

According to different working circumstances and emission requests, the polyester filter cloth can choose various finish treatments, such as water and oil repellent, PTFE suspension bath, PTFE membrane laminated, fire proof and so on so as to make these filter cloths for dust collection with perfect filtration performance.

When the temperature of the dust air is more than 250 degrees C and the dust can not be collected through ESP, then as usual we have to reduce the temperature of the dust air and make it possible to be purified through bag-type dust collectors, but the investment will increase much when this happen.

Due to the fiber glass is fragile and PTFE fiber with a higher heat shrinkage and weak cohesion, to meet the high filter efficiency, both of them need to be laminated with PTFE membrane, which will increase the resistance of the bag filter houses and lower the air/cloth ratio of course, so the polyimide filter cloth (can be P84 filter cloth, PI needle felt, Yilun filter cloth) will become to the first option.

Polyimide (P84 needle felt filter cloth, PI filter cloth, Yilun needle felt) fiber with the properties of good high-temperature resistance, acid resistance and inflammable, the tri-leaves structure of the fiber helps the polyimide needle felt filter cloth with a larger filter surface and with a much higher filter efficiency.

PPS PPS (polyphenylene sulfide, Ryton®, Procon®) is one of the best filter materials with the properties of high-temperature resistance, anti-acid, anti-alkali, and hydrolysis resistant. The PPS filter bags are mainly used for purifying the dust air which includes some acid or alkali materials under high temperatures, such as the thermal power plants boils exhausting gas cleaning, waste incinerators fume removal, etc.

Zonel Filtech adopted the first-grade PPS fiber with sound needle punching processing and surface treatment, chemical treatment, to make the filter bags meet various filtration requirements from clients in different industries.

Zonel Filtech researched and developed a new type of PPS filter bag, without a PTFE membrane, that can control the emission much less than 20 mg/Nm3 at the same air/cloth ratio, the resistance lower 40% at least and offering a much efficient but economical solution for our clients.

PTFE (polytetrafluoretyhylene) also known as Teflon that always be treated as the KING of the plastics due to the properties of high temperature resistance (maximum can stand 280 degree C), corrosion resistance (suitable for PH1~14), longer service life, no-sticky, etc. So, the PTFE fiber is an innate excellent raw material for the industrial filter cloths production. The PTFE filter cloth (teflon filter cloth) from Zonel Filtech mainly offering is PTFE needle felt filter cloth (teflon needle felt filter cloth) as well as the woven PTFE filter fabric. Zonel Filtech adopted the 100% first grade PTFE (Teflon) fiber and PTFE filament scrim, then well needle punched into felt, after the special finish treatment, the Teflon needle felt filter cloth (polytetrafluoretyhylene filter material) can be widely used in various industrial occasions for dust collection (PTFE dust filter bag) and liquid filtration (PTFE / Teflon micron rated filter bag). Zonel Filtech can supply the both PTFE filter cloth rolls (PTFE needle felt for dust collection and PTFE liquid filter cloth/ micron rated PTFE filter cloth) and ready-made PTFE filter bags (Teflon filter bags).

The pulse jet bag filter housing is one of the main products of Zonel Filtech, which is combined with the main filter housing (including the filter bag, filter bag supporting cage, bag tube sheet, tank and hopper, dust discharger, etc), purging system (include press air tank, airbag, pulse jet valve, blowpipe, etc), fan system (include fan with motor, silencer, etc), control system (PLC control) and so on.

Zonel Filtech can help to design bag filter housing according to the work circumstance on the client’s side, also can help them to design the layout of the suction pipe to guarantee the whole filter system will with a perfect performance.

The bag filter housing offering includes the normal bag filter housing, high-temperature bag filter housing, anti-explode bag filter housing, silo bag filter housing, etc. If any help is needed, welcome to contact Zonel Filtech!

The stainless-steel (S.S.) filter housing from Zonel Filtech is designed for liquid and gas/steam filtering applications for various industries, these S.S. filter housings can be used for both primary filtration and high-purity filtrate handling with different micron-rated filter bags or filter cartridges.

The stainless-steel filter housing can be produced with SS 304 and SS316L, which are widely used for food & medical grade liquid or gas/steam filtration even other corrosive chemical and high-temperature materials filtration. The inner and outer surfaces of the SS filter housing can be treated with sandblasting or polishing as requested to make the filters have excellent filtration performance.

All of the SS filter housings from Zonel Filtech are produced strictly according to the standard of GB150.1~150.4-2011, which will be tested thoroughly before the delivery, including raw material testing, high-pressure testing, corrosion testing, and so on.

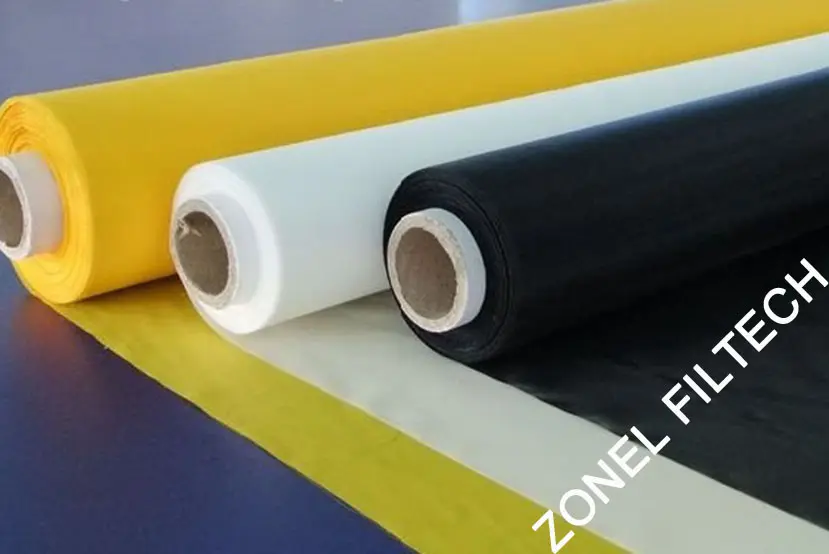

Zonel Filtech is one of the most professional filter materials manufacturers equipped with the most advanced projectile looms and finish treatment machines that can offer the full range of screen meshes / bolting cloth for different industrial occasions for various usages.

Product range: Polyester bolting cloth for printing and general filtration; Polyester flour meshes; Polyamide/nylon bolting cloth for printing and general filtration; Polyamide/nylon flour screening meshes; PP filter mesh/PP screen meshes.

Mesh opening: 25 ~ 1800 micron Width: within 3.6 meters can be customized.

Zonel Filtech provides good quality polyester spun bonded nonwoven fabrics for industrial filtration applications. (filter cartridge media)

The polyester spun bonded filter cloth with the specially designed pattern, combined with the 3D spun-bonded lapping workmanship, make the spun bonded filter cloth from Zonel Filtech with the properties of good air permeability; high filter efficiency; high stiffness, and not easy-to-change shape once pleated; big particles load and durable for various industrial applications. The spun bonded polyester nonwovens from Zonel Filtech can be finished with PTFE membrane laminated, water & oil repellent, and laminated with aluminum foil for anti-static and so on to meet the different requirements from different operating conditions.

Besides the spun-bonded filter cloth, Zonel Filtech also provides the sound quality membrane support layer for pleated-type filter cartridges.

Dust Filter Bags/filter sleeves is the key part of the bag style dust collectors (bag filter houses), which are widely used in many industrial occasions for air pollution control, such as cement plants, thermal power plants, food processing plants, pharmaceutical plants, metallurgy plants, fertilizer plants and chemical plants, etc.

The dust filter bags from Zonel Filtech are made from various filter cloths with sound finish treatment according to different working conditions. The bag size, shape, sewn material, and sealing rings all can be customized professionally.

Besides the dust filter bags, Zonel Filtech also can offer a free consulting service for our clients and help them to improve the performance of their bag filter houses.

If any help is needed, welcome to contact Zonel Filtech!