Home » Products

Products

Categories

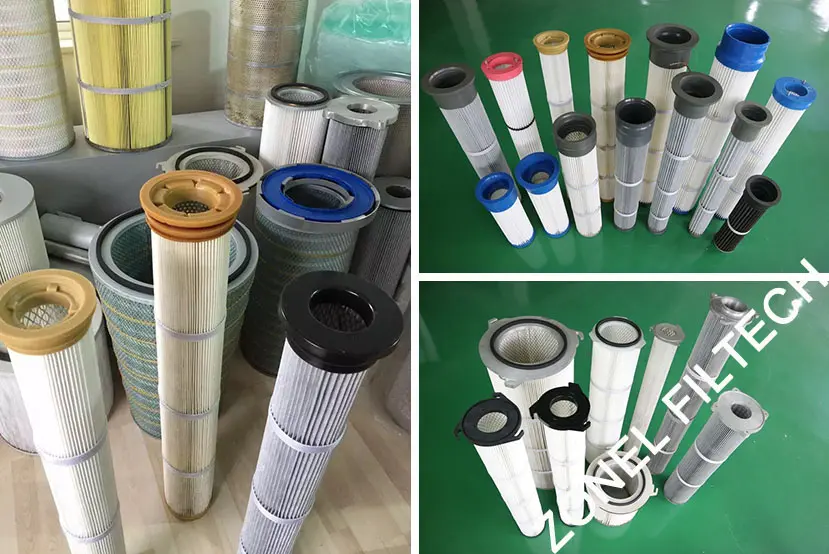

Dust filter cartridges are the key parts of the cartridge dust collectors, according to different systems with the special applications, the cartridge always designed with different caps with the relevant sealing method, different filter material and the glue material, so the professional and experienced supplier will help you to solve all of these kinds of problems in case any possible accident when operating.

Zonel Filtech provide the fully solutions for the replacement filter cartridges nearly for all of the famous brand dust collectors of the world, such as the replacement cartridges for Donaldson® cartridge dust collectors, Nederman® cartridge dust collectors, Amano® cartridge dust collectors, FARR® cartridge dust collectors, Nordson® cartridge dust collectors, etc.

The replacement filter cartridges from Zonel Filtech with the properties of stable and strong construction, big dust load capacity and good air/cloth ratio, long service life, any help needed, welcome to contact us!

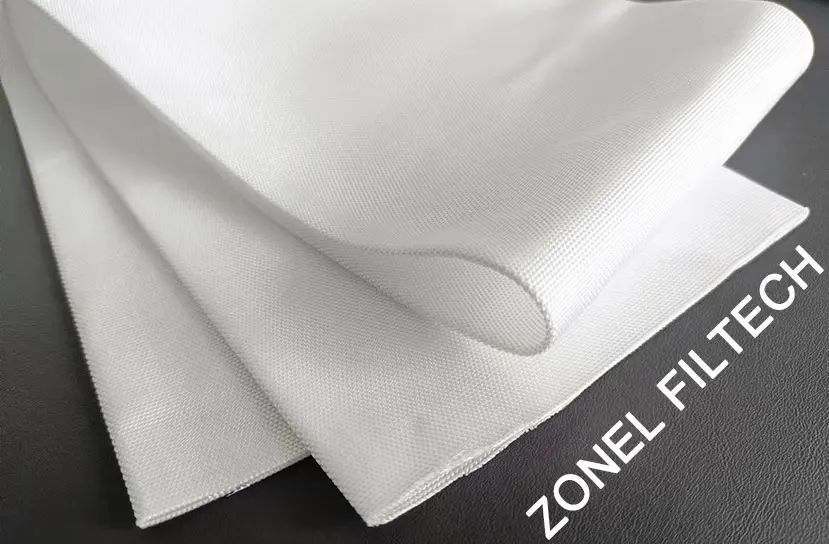

Zonel brand fiberglass filter fabrics are made of E-fiber glass filament/E-fiber glass bulked yarn with some special finish treatment after the weaving works according to the different working conditions to make the glass fiber filter cloth with a much better flexibility, abrasion resistance and also suitable to be used in some special chemical circumstances besides the high temperature so as to prolong the service life of the fiberglass dust filter bags.

Zonel Filtech provides both fiberglass filter fabric rolls and fiberglass ready-made dust filter bags, we also offer free consulting to our clients to help them get the most suitable fiberglass filter bags for their bag filter houses, as well as the relevant filter bag supporting cages for their glass fiber dust filter bags and the accessories of the purging systems, etc.

If any help is needed from Zonel Filtech, just feel free to send the inquiry! Why choose the fiberglass filter bag with PTFE membrane treatment?

Due to the high-temperature resistant chemical fiber filter bags always the extremely high prices which is a heavy burden to the DC operators without doubts for every change. Getting a kind of high-temperature resistant filter bag but with lower cost become to the reality requirement from the filtration market, and fiber glass is the first choice.

The Fiber glass needle felt filter cloth from Zonel Filtech adopted 100% glass fiber, with a sound needle punching and finish treatment, the fiber glass filter bags can be used in some extremely high-temperature occasions for dust collection.

To conquer the disadvantages of weak cohesive, poor folding resistance of the glass fiber felt, ZONEL developed fiber glass blended needle felt(similar to FMS needle felt or FMS filter bag), these fiber glass nonwoven filter materials already with the long time testing, nowadays are widely used for many applications, such as cement, metallurgy, mining, chemical, thermal power plants, etc.

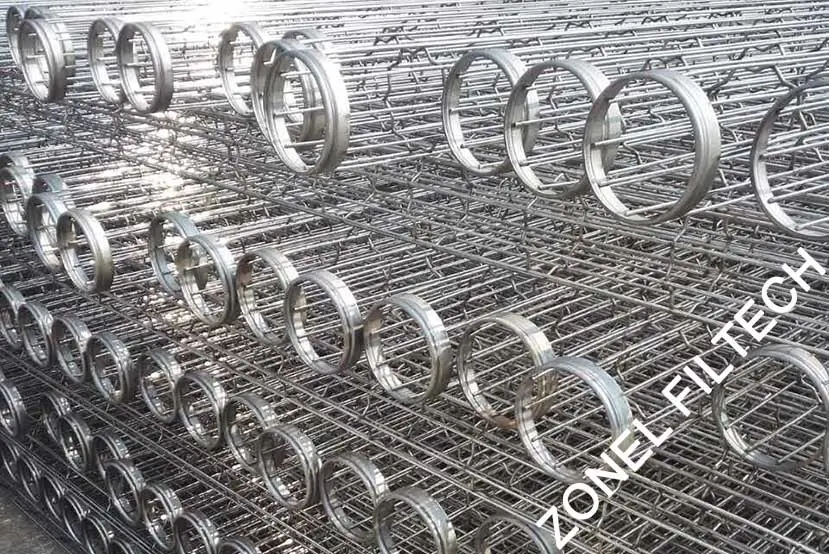

When the pulse jet bag filter house operates, the dust air always comes from outside of the filter bags and the purified air will pass through the filter bags and then exhaust into the atmosphere, during that time bag filter house always with a positive or negative pressure, so a filter bag cage will be put inside of the filter bag to anti-collapse.

The filter cage also called dust collector filter cage or filter bag frame, can be made of galvanized steel, carbon steel with silicon coating, SS 304 or SS316, titanium, and so on for different working conditions.

The filter bag support cage was combined with vertical wires, supporting cages, top caps, and bottom caps, as well as the venturi. To reduce the filter bags’ touch with the supporting rings of the bag supporting cage, we developed the star-shaped side view dust collector filter bag cage; to increase the filter area, we developed the pleated filter bags with the relevant pleated filter bag cages.

The cartridge dust collector with the advanced properties of small size, big air flow volume, high filter efficiency, small investment which are widely used many industrial occasions for dust collection.

Zonel Filtech can provide the oblique installed filter cartridge dust collectors, vertical installed filter cartridge dust collectors, portable dust collector, silo dust collectors, etc.

Besides the dust filter machines, Zonel Filtech also provide replacement filter cartridges for cartridge dust collector for both Zonel made and other OEMs, and special size and usage filter cartridge can be customized.

Welcome to cooperate with Zonel Filtech! (How to choose the suitable cartridge dust collector?)

The SS cartridge filter housing from Zonel Filtech mostly comes with a multi-cartridge designed SS filter housing, which is combined with stainless steel vessel and liquid filter cartridges or air/steam filter cartridges, the solution/airflow direction is from outside to the inner side of the filter cartridges, the filtrate flow out from the inner core of the filter cartridges and the solid particles will be collected at the surface of the filter cartridges.

Filter fabric, filter fabric for filter press, filter press fabric for volatile slurry, corrosive filter press fabric, high pressure filter fabric, rubber coated filter fabric, edge coated filter fabric, edge sealing filter fabric, high sealing filter cloth

Mostly the raw materials for sugar production will be sugar cane and sugar beet, according to the different clarify methods, which can be divided into carbonized sugar (lime+CO2) and sulfurized sugar (lime+SO2) sugar, though the carbonized sugar is more complex and needs much investment on the machines and Clariant, but the general processing principle and procedures are similar. And the filtering process will be requested for sugar slime concentrating after the clarification, sugar juice filtration (after CO2 insert), syrup purification, crystal dewatering processing (centrifuge filters), and wastewater processing, such as sugar cane and sugar beet washing water processing, filter fabric washing water processing, sediment dewatering processing, etc. The filter machine can be filter presses, vacuum belt filters, vacuum drum filters, centrifuge filters, etc. Zonel Filtech is the top expert who can offer full solutions for filter processing for sugar plants, any help needed, please feel free to contact us!

Zonel Filtech provides replacement filter belts for various filter machines, such as horizontal vacuum belt filters (offer vacuum filter belts), belt filter press (offer press filter belt), HVPF belt filters (tower belt filter), drum filters, paper or nonwoven forming machine, etc.

The filter belt can be produced with woven filter fabric belt and nonwoven needle felt filter belt, mainly applied for paper or nonwoven forming (forming mesh belt), juice squeezing (juice squeezing belt), as well as the general sludge dewatering for municipal sewage treatment, coaling washing slurry dewatering, red mud dehydration from the alumina industry, potash fertilizer production, phosphoric acid production, desulphurization gypsum dewatering, etc.

The woven filter belt (filter cloth belt, filter mesh belt) from Zonel Filtech adopted the optimized PET/ PP/ PA monofilament, multifilament, as well as the spun yarn then combined with various weaving patterns and sound finish treatments so as to meet the various filtration requirements for different applications and make them always keep the stable and good filtration performance.

Besides the filter press fabrics and service, Zonel Filtech also can suggest and supply the filter presses according to clients’ solution content and processing circumstances so as to get the best filtration performance but the most economical investment, the filter presses can be frame plate filter press, chamber filter press and membrane filter press, which can be designed to total automatic so as to get the simplest way and shortest time to operate.

Especially the breakthrough in TPE diaphragm technology, filter presses from Zonel with the properties of endurable, stable, universalizable, and widely used in various industries.

Variable filter chamber technology is widely applied on solid-liquid separation in many industries such as chemical, pharmacy, mining, and so on which help to reduce the water content of the filter cake and extremely improved the production efficiency for our clients.

Zonel Filtech is one of the most professional filter materials manufacturers equipped with the most advanced projectile looms-Sulzer and finish treatment machines that can offer the full range of flour meshes. The flour meshes from Zonel Filtech with the properties of equal and punctual open size, high tensile strength, stable size, abrasion resistance, and easy-to-clean, food-grade materials.

Besides the flour meshes, Zonel Filtech also provides the plansifter inlet and outlet sleeves. The plansifter sleeve adopts the polyester filter fabrics, combined with the supporting rings in the middle, double ends with elastic design so as convenient for installation. The plan sifter sleeves for the inlet and outlet from Zonel Filtech with properties of flexible, high tensile strength, breathable but not leak flour, easy to install, and durable, the special size can be customized.

Zonel Filtech also provides good quality plansifter cleaner pads/cotton clean pads, If any help is needed, welcome to contact us!

The gas turbines are widely equipped in thermal power plants of the world, and the premium quality inlet air is crucial for their daily operation and maintenance. For improving the efficiency of the gas turbine and prolong the service life, the upstream filtration is necessary.