Filter Fabric /Filter Fabric For Filter Press/Filter Press Fabric For Volatile Slurry

Filter fabric, filter fabric for filter press, filter press fabric for volatile slurry, corrosive filter press fabric, high pressure filter fabric, rubber coated filter fabric, edge coated filter fabric, edge sealing filter fabric, high sealing filter cloth

General Introduction:

The chamber filter presses playing a quite important role in various industries for their daily production works, and the filter fabrics are the hearts of the filters presses.

But when the operating conditions come with some special properties such as extremely high pressure, volatile slurry treatment, corrosive material treatment and so on, which request the operating without any leaking from the edges parts of the plates, the typical solution is adopt the CGR plates filter presses, while besides the expensive problem, the filter fabric with sealing ropes for CGR plates always can not stand any size tolerance, that will brings much challenges for filter fabric suppliers, or the filter fabrics may can not be installed well, especially the different filter press suppliers, the plate design always have some differences, which always brings much trouble or confusion for end users’ daily maintenance.

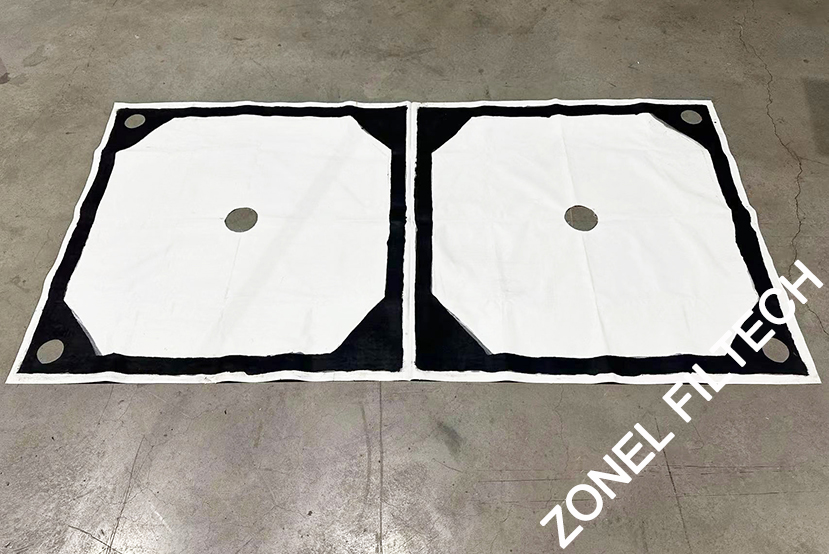

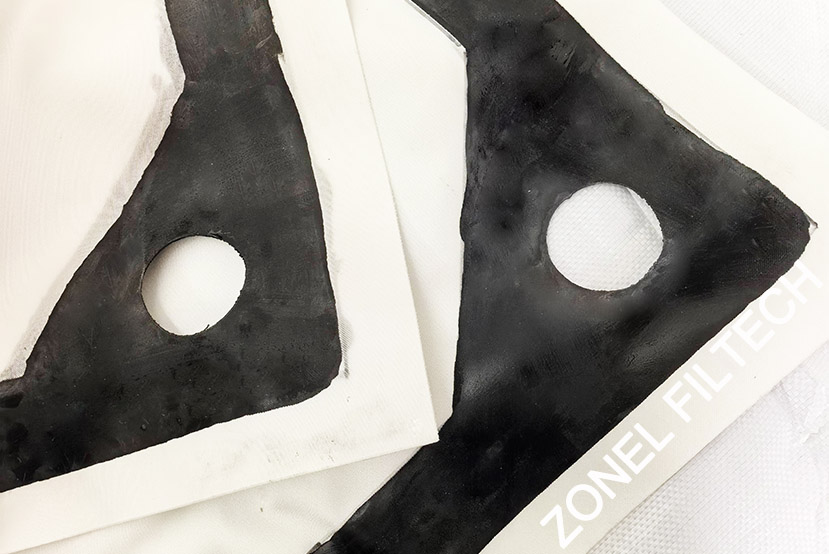

Zonel Filtech developed the rubber coated filter press fabric can solve these problems perfectly.

The rubber will be vulcanized with the fabrics at the edges of the filter press fabrics, so the rubber won’t peel off from the fabric; the rubber coated filter fabric will sealing perfectly and without any leakage; when the filter fabric with rubber coated on the edges that can stand the high pressure without leaking, especially when meet the occasions of volatile and corrosive which will be much safer to operate. And when adopt the different recipe which can meet the FDA standard for food applications, such as the yeast production, etc.

Properties:

1.The rubber vulcanized with the filter fabric, which is stable and won’t peel off from fabric;

2.With good sealing performance, suitable for high pressure processing, volatile slurry treatment, corrosive material treatment, etc;

3.With different recipes, can meet food grade requirements;

4.Automatic rubber coating and vulcanizing workmanship, quality guaranteed;

5.The vulcanizing processing only treated on edge part, which won’t make any shrink, blind or shape change in the filter cloth part, filtration performance stable.

6.Offer the most economical, convenient but effective solutions, fast delivery.

Applications:

For but not limited for the occasions of high pressure filtration, volatile slurry treatment, corrosive material treatment, etc.