Polyester Filter Bags, Polyester Needle Felt Filter Cloth For Dust Filter Bags Production

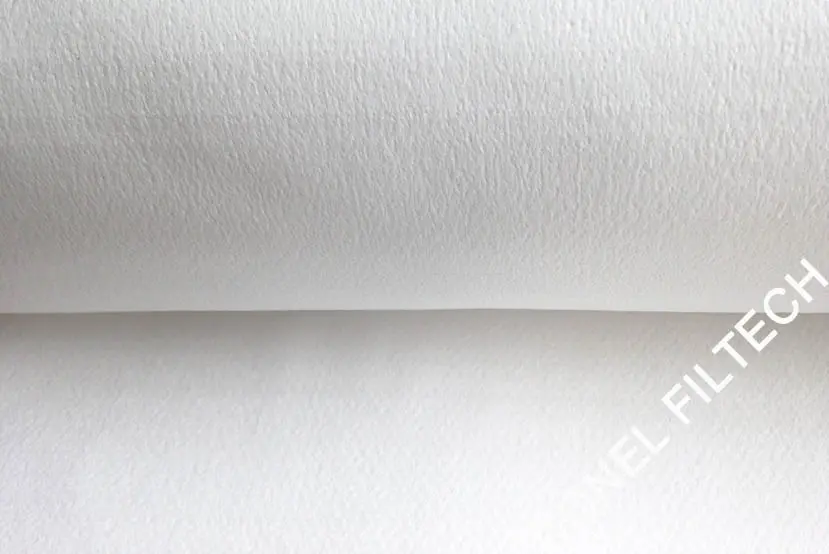

The Polyester (PET, terylene felt) needle felt nonwoven filter cloth with the properties of high tensile strength, super abrasion resistance, good acid resistance, and food grade, one of the most economical filter materials that is widely used in various industrial applications for dust collection usage (dust filter cloth for dust filter bags production).

Zonel Filtech with the most experienced and skillful team, owns the modern needle punching lines combined with first-grade raw materials to make the polyester needle felt filter cloth from Zonel with equal air permeability and thickness, high tensile strength, smooth surface and easy release the dust cake, durable.

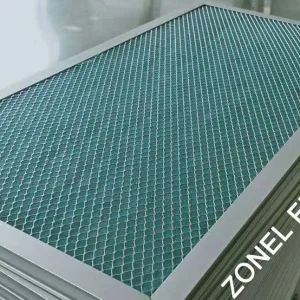

According to different working circumstances and emission requests, the polyester filter cloth can choose various finish treatments, such as water and oil repellent, PTFE suspension bath, PTFE membrane laminated, fire proof and so on so as to make these filter cloths for dust collection with perfect filtration performance.

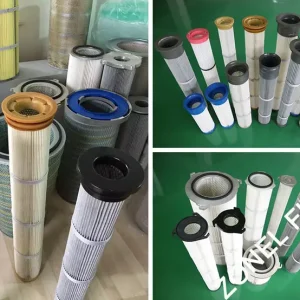

Polyester needle felt filter cloth for dust filter bag production/ polyester dust filter bags

General introduction of the polyester needle felt filter cloth:

The Polyester (PET, terylene felt) needle felt nonwoven filter cloth with the properties of high tensile strength, super abrasion resistance, good acid resistance, and food grade, one of the most economical filter materials that is widely used in various industrial applications for dust collection usage (dust filter cloth for dust filter bags production).

Zonel Filtech with the most experienced and skillful team, owns the modern needle punching lines combined with first-grade raw materials to make the polyester needle felt filter cloth from Zonel with equal air permeability and thickness, high tensile strength, smooth surface and easy release the dust cake, durable.

According to different working circumstances and emission requests, the polyester filter cloth can choose various finish treatments, such as water and oil repellent, PTFE suspension bath, PTFE membrane laminated, fireproof and so on so as to make these filter cloths for dust collection with perfect filtration performance.

Relevant products:

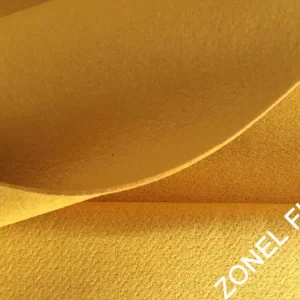

Acrylic needle felt filter cloth and filter bag

Polyester anti-static needle felt filter cloth and filter bag

Relevant specifications for the polyester needle felt

Material: Polyester (PET, terylene) fiber, supported with polyester high tensile strength & low elongation scrim

Weight:300~750g/sq.m

Operation Temperature: Continues: ≤130℃; Peaks: 150℃

Surface treatment available: singed & glazed, heat set, PTFE suspension bath, PTFE membrane. We can customize the products according to the requirements of the clients!

The properties of the polyester dust filter bags and services from ZONEL FILTECH

1. with the professional technical team, design according to the client’s requirements, good performance is guaranteed.

2. Emission within requirements, lower initial resistance, not easy to be blocked.

3. Operation suggestions will be offered, not easily broken, and durable.

4. All the sizes and finish treatments available, immediate delivery.

5. The whole day 24 hours offer after-sales services and faster response.

Applications of polyester needle felt filter bags

1. Chemicals processing: dryers, bin vents, and nuisance dust collectors in the pigment, plastic, and catalyst industries

2. Minerals processing: finish mills, raw mills, bulk pneumatic conveying, and bin-vent dust collectors

3. Metals processing: process-venting dust collectors in the lead, lead oxide, and iron and steel industries. Pulverized coal injection systems, fume and bulk handling systems in coke production, and sand-reclamation systems in foundries

4. Power generation and Incineration: material handling for coal and limestone

5. building materials: such as cement plants, bricks plants, etc for dust collection.

6. food processing plants such as milk powder plants, flour plants, etc.

Zonel

ISO9001:2015