Table of Contents

ToggleWhy choose the PPS dust filter bags for thermal power plant application

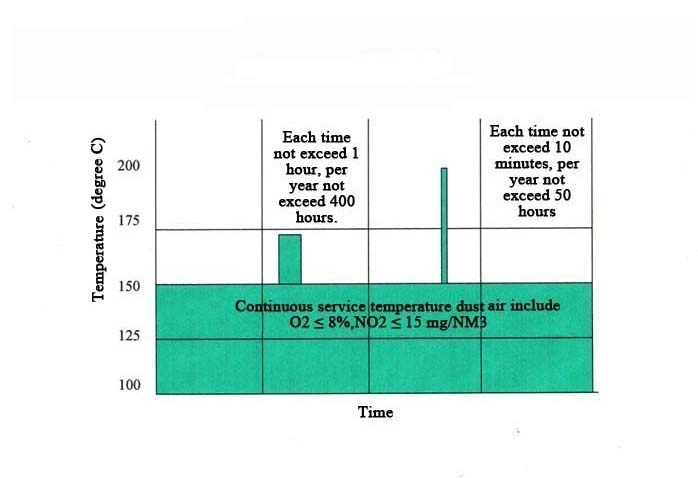

Generally, the flue gas needs to be filtered from thermal power plants which means the flue gas exhausts from their boilers (can be coal-fired, oil-fired, bio-mass fuel-fired boilers, and so on). Due to the exhaust gas including SOx, NOx, CO, CO2, as well as some fine ashes, it is very easy to get an acidic circumstance, especially when the temperature lowers, acid dew may exist, this is the main reason for us to choose the PPS filter bags. Following are some performance curves for the operating limitation of the PPS filter bags for your reference:PPS filter bag, temperature – Time

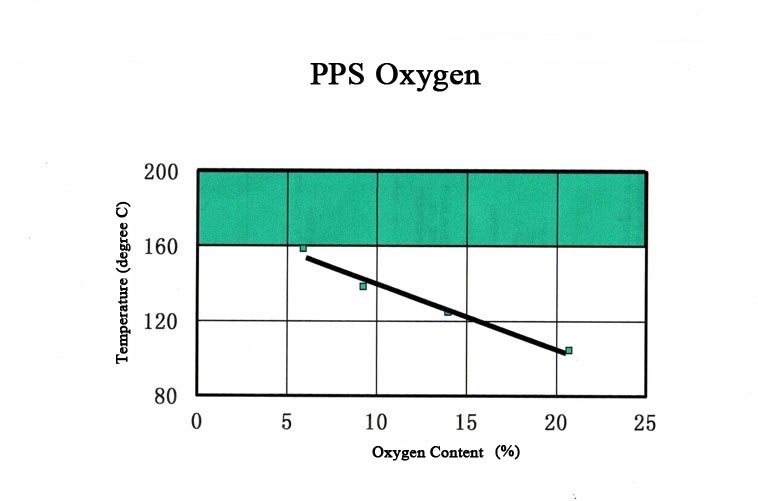

PPS filter bag, Temperature – Oxygen

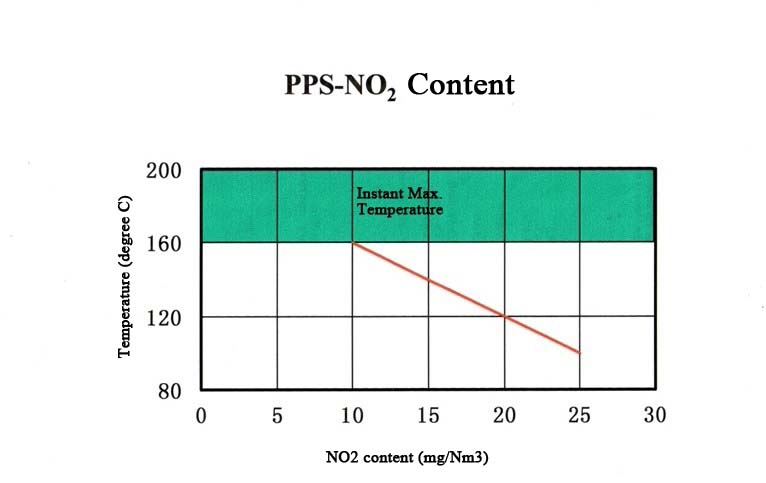

PPS filter bag, Temperature – OxygenPPS filter bag, Temperaure – NOx

But due to the PPS filter bags is sensitive to the oxidant, such as the Oxygen and NOx, so which always need much surface treatment before to use them, and it’s very good that Zonel Filtech can solve these problems well.

But why choose the PPS filter bags for power plants exhausting gas purifying from Zonel Filtech? The reason as following:

1.Emission < 20mg / Nm3 at initial resistance < 1000Pa @ a/c ratio 1.2m/min; minimum can be 5mg/Nm3 at initial resistance < 1400Pa @ a/c ratio 1.2m/min.

2.Innovative surface treatment, lower resistance, longer purging period, prolong the service life of the filter bags.

3.Easy install and maintenance, offer the whole range after sales service.

4.Innovative equipment and action pattern of Zonel Filtech.

5.Professional engineers and skillful workers, think all for the clients.

If there are any questions, please feel free to contact ZONEL FILTECH!