Home » News

News

Categories

Apr 5, 2022

Besides the filter materials and filter machines, Zonel Filtech also offers free consultant on dust collector technology support, so we always can receive some technical support requirements from our clients and potential clients, when some questions are mentioned, we may edit some articles then release in our catalog to help our reader to solve the possible problems for their dust collectors, this article will explain the emission exceed problems.

Mar 13, 2022

According to the client’s description from the cement plant they adopted the vertical mill for the raw meal preparation, then conveying through an air slide chute system (630X79500mm), the angle of inclination is 8 degrees, with 2 blows (18.5KW). Recently, many blocking problems happened at the upper side of the air slide system (around 800mm to cyclone), always happens when the mill starts to work, but when the mill operating for some time, the blocking problem disappears.

Mar 6, 2022

The air slide chute conveying system is an extreme form of airtight pneumatic conveying method, which uses low-pressure air to pass through the air slide fabrics to achieve the purpose of powder/particle conveying.

The compressed air disperses after passing through the air slide fabric and enters around the particles, which overcomes the resistance of the particles and air slide fabrics, so that the particles become to fluidization conditions like liquid, then flows by gravity in the tank.

Compared with some mechanical conveying systems, the air slide chute system with the properties of no rotating parts, no noise, convenient operation and management, light equipment weight, low energy consumption, simple structure, large conveying capacity, and easy to change the conveying direction. Very economical equipment for conveying powdery materials and granular bulk solids.

Feb 2, 2022

As the dust collection technology develops, more and more dust collecting methods are invented and improved, because of the advantages of high filter efficiency and stable lower dust emission, the bag style dust filters are the most popular dust filters nowadays, and the pulse jet bag filter house is the most popular bag filters due to the broad adaptability.

Jan 27, 2022

The reasons to choose the fiber glass filter bag with PTFE membrane treatment:

the high tensile strength:

The tensile strength of the fiber glass filter fabric is more than 4000N/50mm as usual, which is much higher than chemical fiber filter materials and the blended filter materials, which is very suitable for the long filter bags sewing.

Anti-corrosion

Fiber glass filter bag can keep a good performance in the circumstance of acid and alkali (except hydrofluoric acid and strong phosphoric acid).

Jan 27, 2022

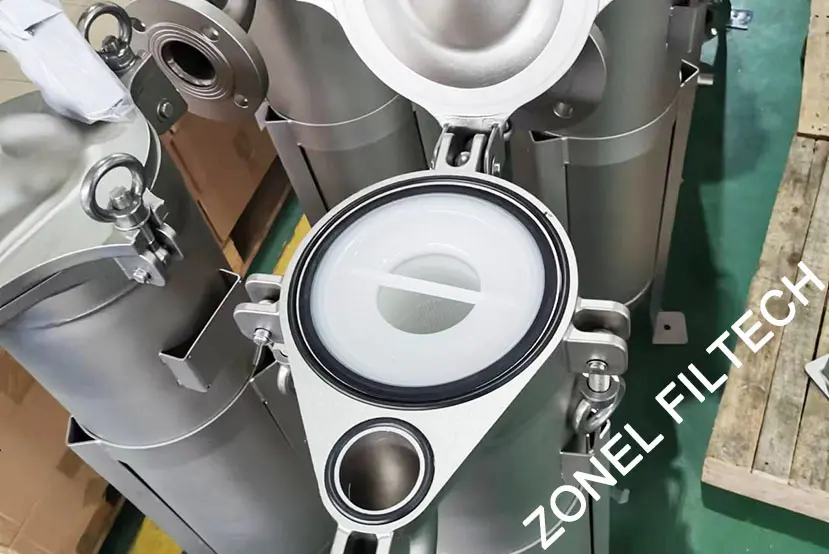

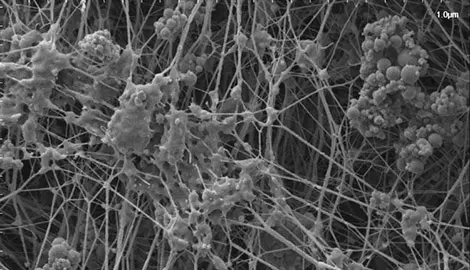

The properties of the filter cloth with PTFE membrane laminated.

better filter efficiency

The PTFE membrane with a cross micro open size can filter very tiny dust (fume), especially good for ultra-fine dust collection, and lower emission.

lower resistance

The filter cloth with PTFE membrane which collects the dust is a kind of surface filtration, the surface is smooth which is very good for bag purging works, so it’s not easy to block or even filter the ultra-tiny dust and wet dust, so the average resistance is lower when compared to the normal filter materials.

Jan 27, 2022

The air pollutants from cement production and the relevant solutions.

The air pollutants from cement production mainly are dust and flue gas.

The dust mainly comes from the following procedures:

1. the raw materials preparation

A.CaCO3 crush.

B.Clay drying

C.Coal grinding and feeding.

D. Raw meals grinding.

Jan 25, 2022

Why some filter bags/ filter cartridges need water and oil repellent treatment?

We always receive questions from the end users of the dust collectors as that why the filter bags/filter cartridges need to make the finish treatment of water oil repellent.

The answer is that for some filtration circumstances, this treatment will improve the performance and prolong the service life of the dust filter bags/dust filter cartridges.

Generally speaking, following situation we consider it easy to dewing: