Liquid filter bags play a vital role in numerous industrial and commercial settings, primarily functioning to eliminate contaminants from liquids. Proper maintenance and care of these filter bags not only ensure optimal performance but also extend their lifespan, reducing costs and downtime.

This article offers practical advice on maintaining liquid filter bags, covering cleaning techniques, and proper storage, and handling practices.

Table of Contents

ToggleUnderstanding Liquid Filter Bags

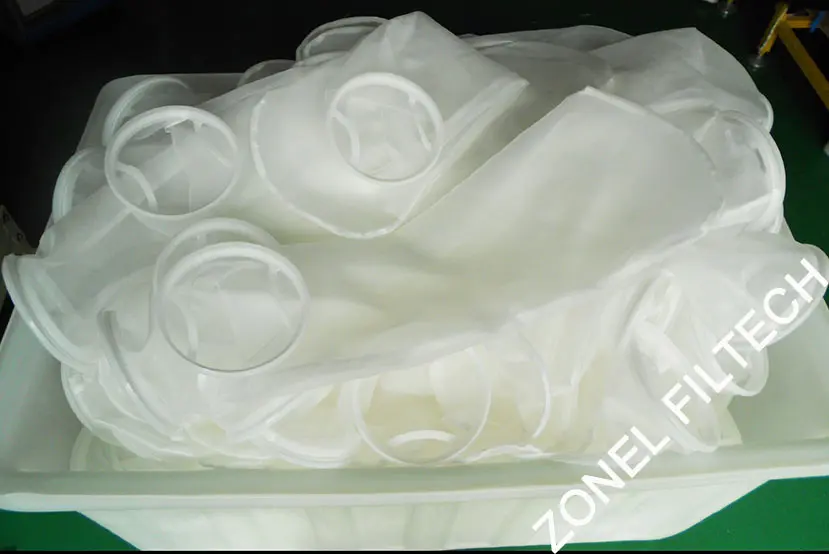

Liquid filter bags are used in filtration systems to trap particles, ensuring the purity of liquids in processes such as chemical manufacturing, food and beverage production, and wastewater treatment. These bags can be made from various materials including nylon, polyester, and polypropylene, each suitable for different applications and offering varying degrees of filtration.

Cleaning Techniques

Maintaining the cleanliness of liquid filter bags is crucial for preserving their efficiency and extending their lifespan. The appropriate cleaning method often depends on the type of material and the contaminants involved:

- Mechanical Shaking or Vibration: This method is suitable for dislodging loose particles from the filter fabric. It’s a gentle approach that can help prevent damage to the bag.

- Backwashing: For some filter systems, backwashing can be an effective way to clean filter bags. This method reverses the flow of liquid to expel trapped particles. It is crucial to ensure that the filter material can withstand the pressure involved in backwashing.

- Chemical Cleaning: Some filter bags may require chemical cleaning agents to remove oils, fats, and other sticky substances. It’s important to use chemicals that are compatible with the bag’s material to avoid degradation. Always rinse the bags thoroughly after chemical cleaning to remove any residues.

- Ultrasonic Cleaning: For filters that capture very fine particles, ultrasonic cleaning can be an effective method. This technique employs high-frequency sound waves to generate cavitation bubbles that agitate and dislodge particles from the bag.

Proper Storage

Storing liquid filter bags properly is critical to ensure they remain in good condition and ready for use:

- Dry Storage: Always store filter bags in a dry environment to prevent mold and mildew growth, which can degrade the material and reduce filtration efficiency.

- Temperature-Controlled Environment: Extreme temperatures can damage filter materials. Store bags in a temperature-controlled environment to maintain their integrity.

- Avoid Direct Sunlight: UV exposure can weaken synthetic materials. Store filter bags away from direct sunlight.

- Original Packaging: If feasible, store filter bags in their original packaging to shield them from dust and various environmental contaminants.

Handling Practices

Proper handling of liquid filter bags is essential to prevent damage and contamination:

- Gentle Handling: Avoid rough handling, which can cause tears or stretches in the bag material. Always lift and carry bags with care.

- Use Clean Gloves: When installing or removing filter bags, wear clean gloves to prevent oils and dirt from your hands from contaminating the bags.

- Check for Damage: Consistently examine bags for any indications of wear or damage before and after usage. Small holes or tears can significantly reduce the effectiveness of the filtration.

- Regular Replacement: Despite best maintenance practices, filter bags do wear out and should be replaced regularly to ensure optimal performance. Keep track of usage and pressure drop across the filter to determine when replacements are needed.

Conclusion

Effective maintenance and care of liquid filter bags are critical to maximizing their lifespan and ensuring efficient operation of filtration systems. By implementing proper cleaning techniques, ensuring correct storage, and handling bags with care, businesses can achieve better filtration results, reduce operational costs, and minimize environmental impact.

Regular checks and timely replacements are also vital to maintain the system’s overall health and effectiveness. By following these guidelines, you can significantly extend the life of your liquid filter bags and ensure they perform at their best.