Liquid Filter Cartridges

Besides the S.S. filter houses, Zonel Filtech also provides various replacement filter cartridges for liquid filtration, the micron size, materials, product size, and connections of the liquid filter cartridges all can be customized according to different usages.

The micron-rated liquid filter cartridge from Zonel Filtech mainly includes PP melt blown filter cartridge series (spun bonded / thermal bonded filter cartridge); phenolic resin bonded filter cartridge, the string wound filter cartridge series (including PP string wound filter cartridge, bleached cotton string wound filter cartridge, fiberglass string wound filter cartridge); the micro pleated filter cartridge series; big flow filter cartridge series.

The liquid filter cartridges from Zonel Filtech are mainly used for pre-filtration of RO, food & beverage filtration, chemicals filtration, pharmaceutical material purification, organic solvent filtration, etc.

If any liquid filtration cartridges are needed, you are welcome to contact Zonel Filtech!

PP melt-blown filter cartridges

General description of PP melt blown filter cartridge:

The PP melt blown filter cartridge (PP spun bonded filter cartridge) from Zonel Filtech with NSF approval, adopted the 100% PP virgin resin with the procedures of PP resin melting, fiber blowing/spraying, stretching, and spun bonding so as to make the product into a hose shape and suitable for filtration usage in various designs of the S.S. filter houses.

The PP spun filter cartridge is a kind of depth filter cartridge without any extra adhesives (resin bonded filter cartridge design), with 3 layers design according to different pore sizes and with the properties of chemical resistance, high filter efficiency, big flow volume, lower resistance, big particles loading, small size, can stand high pressure, various application, etc.

The factory has 6 production lines (3 melt blown heads with automatic design) and an output capacity up to 15000 pcs per day, we accept customizing orders with the various requirements from clients, fast delivery is guaranteed, welcome to cooperate with Zonel Filtech!

Properties:

1. The PP spun filters from Zonel Filtech adopt the 100% PP new material, food grade.

2. With 3-layer PP thermally bonded construction (thermally bonded PP micron fiber filter cartridge), with high filter efficiency, big flow volume, lower resistance, big particle loading, and durability.

3. The spun bonded PP filter from Zonel Filtech with good chemical resistance and massive applications.

4. The Zonel PP melt-blown filter cartridge with high filter efficiency, small size, and high resistance design, offers the most economical solutions for filtration.

Application:

1. Pre-filtration for drinking water. (both home and industrial usage, polypropylene sediment water filter cartridge).

2. Pre-filtration for RO system (spun-bonded water filter cartridge).

3. Pure water filtration for electronic / power industries (oil absorbing filter cartridge, etc.)

4. For filtration in oil and gas industries, chemical industries, mining, metallurgy industries, etc.

5. Food and beverage industries.

6. Pharmaceutical industries.

7. Air filtration for various occasions.

More details:

1. Material available

A. Filter material of the PP melt blown filter cartridge: 100% PP (can be designed with smooth surface, needle punching surface, grooving surface, etc.)

B. Core material of the PP spun bonded filter cartridge: PP, SS304, SS316C. Connection of the melt-blown filter cartridges: DOE, 215, 222, 34, etc.

2. Size information of the PP spun filters:

A. Length: 5~50”

B. OD: 45~120mm

C. ID: 20mm, 28mm, 30mm, 32mm, 34mm, 38mm, 60mm, 90mm

D. Filter efficiency: 0.5 micron, 1 micron, 5 micron, 10 micron, 20 micron, 30 micron, 50 micron, 100 micron.

3. Main function data of the PP melt blown filter cartridge:

A. Efficiency and flow volume of the PP melt blown filter cartridge:

Filter efficiency | 1 | 3 | 4 | 10 | 20 | 30 | 50 |

Initial opening | 10~15 | 15~25 | 25~35 | 30~40 | 35~50 | 40~60 | 60~90 |

Max. opening | 15 | 25 | 35 | 40 | 50 | 60 | 90 |

Volume (L/min) | 10 | 14 | 17 | 20 | 24 | 28 | 32 |

Note:The cartridge tested with the length of 10”, pressure 0.2MPa, testing media is water.

B. Suggest maximum operating pressure: 0.5MPa; maximum pressure drop: 0.2MPa.

C. Suggest maximum operating temperature: 60-degree C.

Phenolic Resin bonded filter cartridge

General introduction:

The phenolic resin filter cartridge which adopted the phenolic fiber blended with cohesive, hardener, stabilizer, and so on then sintered into the filter cartridges, to improve the strength of the phenolic fiber, which can blended with polyamide (5~10%) when production.

The phenolic resin filter cartridge from Zonel Filtech has fiber bonded outer to inner with gradually tighter construction, which makes them with bigger particle loading capacity, good strength, and durability.

The properties:

1. The sintered bonded method, with a higher pore rate, big liquid flow, equal pore size;

2. The outer to inner with gradually tighter construction makes the filter cartridges with a bigger particle loading capacity, good strength, and durable;

3. The surface of the filter cartridges with groove design, with the bigger filter surface;

4. With the AI auto production system, stable quality control and filter efficiency;

5. The phenolic resin filter cartridge is chemical resistant, wide applications;

6. Bonded with acrylic acid longer fiber makes the phenolic resin filter cartridge with a stable fiber layout, the fiber not easy to break and move, reducing the second pollution to the solution;

7. Insert the phenolic resin to make the filter cartridge stronger, which can stand a viscosity of up to 15000SSU (3200CKS);

8. The phenolic resin filter cartridge with an oxygen limit index of up to 34, fireproof, maximum operating temperature can up to 145 degrees C;

Applications:

The phenolic resin filter cartridges are mainly used for the following solutions filtration:

Cars painting, electrophoretic paint, ink, printer ink, can coating paints, UV curing ink, conductive ink, various emulsion, color paste, liquid dye, organic solvents, as well as some special chemicals, mechanical wastewater treatment, etc.

Technical details:

1. The length of the filter cartridge:

10”, 20”, 30”, 40”

Special requests can be customized.

2. The filter efficiency:

1 micron, 3 micron, 5 micron, 10 micron, 15 micron, 25 micron, 50 micron, 75 micron, 100 micron, 125 micron, 150 micron, 200 micron, 250 micron.

3. Outer diameter: 65+/-2mm

4. Inner diameter: 29+/-0.5mm

5. Maximum operating temperature:

145 degree C.

6. Suggest flow volume(10”):

5micron: 22L/min

10micron: 31L/min

>50micron: 38L/min

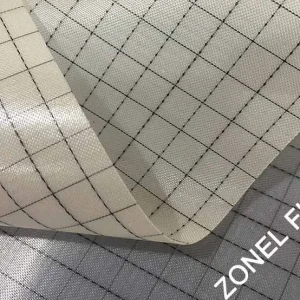

Wound filter cartridges

General introduction of wound filter cartridges:

The string wound filter cartridge from ZONEL FILTECH with an NSF certificate, is a king of depth sediment filtration cartridge and suitable for low viscosity, low particle content liquid filtration.

The wound filter cartridge adopted the suitable strings/yarn (such as PP yarn/ bleached cotton thread/fiberglass string, etc.) and then winded on porous cages (material can be PP, SS, etc.) with certain workmanship to meet the different micron rates, the cellular construction with the micro-fiber adopted to make the filter cartridges with the perfect performance to removal the particles in suspensions.

The micro-fiber filter cartridge is widely used for industrial water filters, drinking water filters, chemical filters, oil filters, painting filters, etc.

The factory has 28 sets of automatic production lines and an output capacity of up to 15000 pcs per day, we accept customizing orders with the various requirements from clients and fast delivery We are welcome to cooperate with Zonel Filtech!

The properties of the wound filter cartridges from Zonel Filtech:

1. High filter efficiency, low resistance, high flow volume, and big particle loading.

2. The pore size is big to small from the outer side to the inner side, depth filtration, is durable.

3. The filter cartridge can be produced with various materials according to different filtration requirements so as to keep a perfect filtration performance.

Technical details of the wound filter cartridges:

1. Material available

A. Filter material of the string wound filter cartridge: PP microfiber thread (PP string wound filter cartridge), bleached cotton string (cotton wound filter cartridge), fiberglass yarn (fiberglass string wound filter cartridge with continuous filament string, for high-temperature filter cartridge production, small fiber lost), etc.

B. Core material of the poly wound string wound filter cartridge: PP, SS202, SS304, SS316

C. Connection of the thread wound filter cartridge: DOE, 215, 222, 34, 304 thread design, etc.

2. Size information of the wire wound filter cartridges:

A. Length: 5~70”

B. OD: 55~115mm

C. ID: 28mm, 30mm

D. Filter efficiency: 0.5 micron, 1 micron, 5 micron, 10 micron, 20 micron, 30 micron, 50 micron, 100 micron, 150 micron.

3. Main function data of the wound filter cartridges:

A. Efficiency and flow volume of the wound filter cartridge:

Filter efficiency | 0.5 | 1 | 3 | 5 | 10 | 20 | 30 | 50 |

Volume (L/min) | 6 | 9 | 12 | 18 | 30 | 37 | 42 | 44 |

B. Suggest maximum operating pressure: 0.5MPa; maximum pressure drop: 0.2MPa.

C. Suggest maximum operating temperature: PP + PP core: not exceed 70 degree C; PP+SS core: not exceed 90 degree C; bleached cotton + SS core: not exceed 120-degree C.

Micro pleated filter cartridges

Big flow volume filter cartridges

General introduction:

ZHFV series filter cartridge is one of the main products from Zonel Filtech, which is a kind of high flow volume filter cartridge, with the size of OD6”/152mm, and without center core, with one end open, the liquid suspension flow from the inner side to the outer side, all the particles will be collected at the inner side of the cartridges.

The bigger diameter design increases the filter area, which can reduce the qty of the cartridge needed and reduce the size of the filter housing as well.

The filter cartridges with the properties of higher flow volume, are much more durable and offer very economical filtration solutions for various industrial applications.

Relevant parameters:

Diameter: 6” (152mm)

Length: 20”, 40”, 60”

Filter material: filter glass, PP (polypropylene)

Supporting layer/flow guiding layer: PP

Caps: PP with fiberglass strengthened

Sealing rings: silicon rubber, Viton, EPDM.

Filter efficiency: 1, 5, 10, 20, 40, 70, 100 micron.

Maximum operating temperature: 82 degrees C.

Maximum operating resistance: 3.44 bar, 82 degrees C

Suggest cartridge changing resistance: 2.4 bar @ 20 degrees C.

Order model confirmation: (Example: ZHFV-40-PP-05-E)

Cartridge type | Length (inch) | Connection | Precision (micron) | Sealing material |

ZHFV | 20=20” (508mm) | PP=single sealing ring | 01=1 micron | S= silicon rubber |

GF=double sealing ring | 05=5 micron | E=EPDM | ||

10=10 micron | V=Viton | |||

20=20 micron | ||||

40=40 micron | ||||

70=70 micron | ||||

H1=100 micron |