Home » Liquid Filter » Page 2

Liquid Filter

Categories

The magnetic filter also called strong magnet iron remover, which combined with several permanent magnetic rods with a specially designed magnetic circuit, when the liquid passes by, the iron particles (0.5~60 microns) or other tiny magnetic objects in the polluted solution will be absorbed on the magnetic rods to clean the liquid according to the design or requirements.

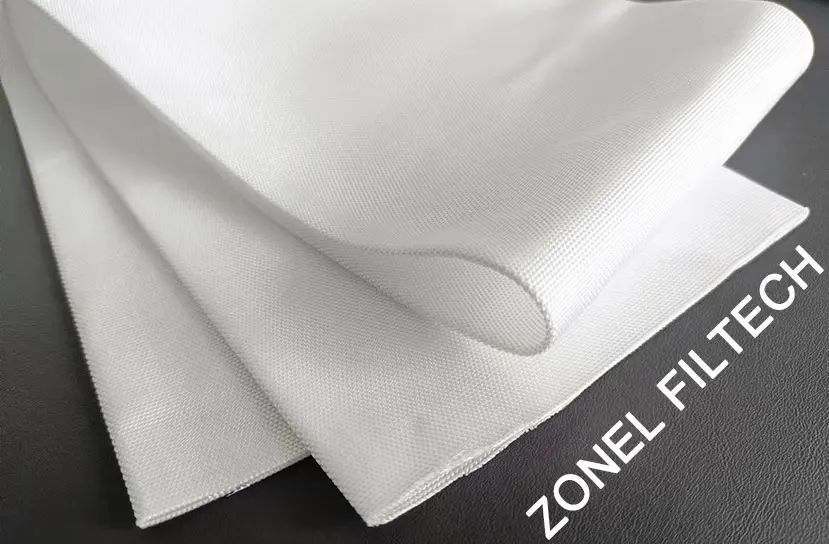

Zonel Filtech was dedicated to micron-rated liquid filter bags and filter cloth for many years, the liquid filter material including nonwoven filter felt and woven filter mesh, both filter cloth rolls and ready-made filter bags are available, the micron sizes from 0.2~1800 can be customized.

The nonwoven micron-rated filter cloth from Zonel Filtech adopted 100% first-grade polyester or polypropylene fibers to needle punched into felt, after some finish treatment according to the standard workmanship so as to make the filter cloth meet the most critical liquid-solid separation needs.

Zonel Filtech provides both primary liquid filter bags and absolute-rated filter bags which are widely used for industrial applications in various plants, such as the fine chemical industry, electronic industry, automobile production plants, food and pharmaceutical industries, paper production plants, oil and gas refinery industries, metallurgy industries, etc.

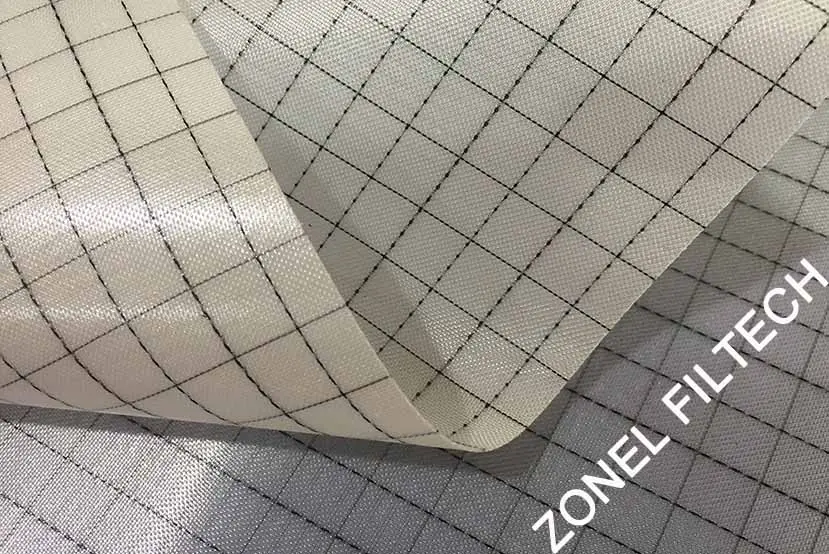

Zonel Filtech offers various filter materials for crude palm oil filtration which is equipped on many kinds of filter machines, the palm oil filter material is mainly adopted for: 1. For filter press machines Zonel Filtech developed the PA66 and PET/PBT monofilament anti-static filter fabrics for chamber filter press machine to the crude palm oil filtration. The properties of the palm oil filter fabrics: Food grade; anti-static (the antistatic palm oil filter cloth won’t generate static sparks, with safe production); smooth surface and easy cake release; high tensile strength and abrasion resistance, stable size, durable. The filter press filter fabrics for palm oil filtration is quite popular in the market, If any help is needed for palm oil filter cloth, welcome to send us an inquiry! 2. For SS bag filter housing …

Zonel Filtech developed the para-aramid filter cloth (Kevlar filter fabric) / filter bags for candle filters which widely used for Raney Nickel collection in reactor for BDO production (ethyne method, as the BDO reactor filter bag or BDO catalyst filter bag) process, etc.

The BDO production process is that acetylene and formaldehyde pass through the catalyst (Raney nickel catalyst) slurry layer in countercurrent, and react at 93°C, 0.1 MPa with the catalyst. The stirrer and the acetylene gas entering from the lower part of the reactor can keep the catalyst in suspension.

The phenolic resin filter cartridge which adopted the phenolic fiber blended with cohesive, hardener, stabilizer, and so on then sintered into the filter cartridges, to improve the strength of the phenolic fiber, which can blended with polyamide (5~10%) when production.

The phenolic resin filter cartridge from Zonel Filtech has a fiber bonded outer to inner with gradually tighter construction, which makes them with a bigger particle loading capacity, good strength, and durability.

The stainless-steel (S.S.) filter housing from Zonel Filtech is designed for liquid and gas/steam filtering applications for various industries, these S.S. filter housings can be used for both primary filtration and high-purity filtrate handling with different micron-rated filter bags or filter cartridges.

The stainless-steel filter housing can be produced with SS 304 and SS316L, which are widely used for food & medical grade liquid or gas/steam filtration even other corrosive chemical and high-temperature materials filtration. The inner and outer surfaces of the SS filter housing can be treated with sandblasting or polishing as requested to make the filters have excellent filtration performance.

All of the SS filter housings from Zonel Filtech are produced strictly according to the standard of GB150.1~150.4-2011, which will be tested thoroughly before the delivery, including raw material testing, high-pressure testing, corrosion testing, and so on.

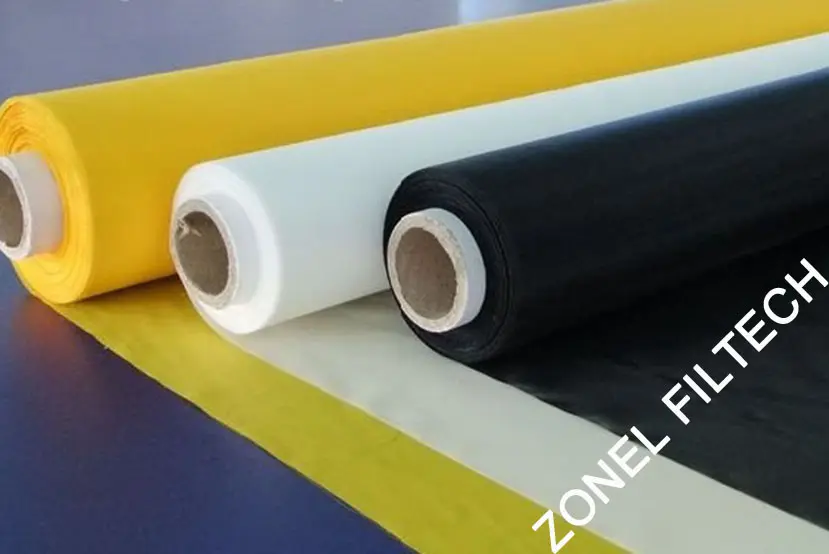

Zonel Filtech is one of the most professional filter materials manufacturers equipped with the most advanced projectile looms and finish treatment machines that can offer the full range of screen meshes / bolting cloth for different industrial occasions for various usages.

Product range: Polyester bolting cloth for printing and general filtration; Polyester flour meshes; Polyamide/nylon bolting cloth for printing and general filtration; Polyamide/nylon flour screening meshes; PP filter mesh/PP screen meshes.

Mesh opening: 25 ~ 1800 micron Width: within 3.6 meters can be customized.

Zonel Filtech provides good quality polyester spun bonded nonwoven fabrics for industrial filtration applications. (filter cartridge media)

The polyester spun bonded filter cloth with the specially designed pattern, combined with the 3D spun-bonded lapping workmanship, make the spun bonded filter cloth from Zonel Filtech with the properties of good air permeability; high filter efficiency; high stiffness, and not easy-to-change shape once pleated; big particles load and durable for various industrial applications. The spun bonded polyester nonwovens from Zonel Filtech can be finished with PTFE membrane laminated, water & oil repellent, and laminated with aluminum foil for anti-static and so on to meet the different requirements from different operating conditions.

Besides the spun-bonded filter cloth, Zonel Filtech also provides the sound quality membrane support layer for pleated-type filter cartridges.

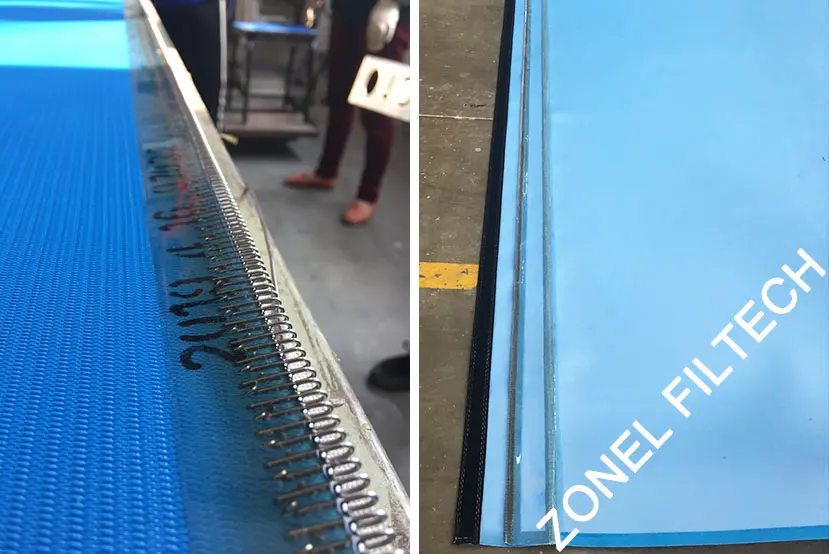

The wet processing workmanship for phosphoric acid production with the properties of most mature on technology, most economical method, which is the most popular workmanship for phosphoric acid producing. No matter the method of DH, HH-DH, DH-HH, HH, for getting the clean phosphoric acid; get the high P2O5 collection rate, most factories will equip the vacuum filters with vertical washing system to separate the phosphoric acid with the solid particles, the filters can be rubber belt vacuum filters, disc filters and pan filters, etc.

The filter system is one of the most complex construction and most expensive equipment for the phosphoric acid plants, how to get a higher working efficiency of the filters which is crucial for the phosphoric acid output, P2O5 collection rate and quality, as the heart of the filters, the filter fabrics/filter belt playing a very import role of course.

According to the requirements from the coal preparation plants, Zonel Filtech developed several kinds of filter fabrics for the coaling washing process so as to help them to concentrate the coal slurry and purify the wastewater when coal washing processing, the filter fabrics from Zonel Filtech for coal washing works with the properties of: 1. Under the certain filter efficiency with good air and water permeability, very suitable for fine coal slurry concentrating. 2. Smooth surface, easy cake release, reduce the maintenance cost. 3. Not easy to block, so reusable after wash, longer using life. 4. Material can be customized according to different working conditions.

The yeast production is somewhat like farming processing, which includes the procedures of preparation, seeding, cultivation, and harvesting, so getting a proper filter fabric for yeast harvesting is crucial, which will be helpful for the end user to increase the output and reduce the lost so as to make their products much more competitive, also helpful for the pollution control when production.

Due to the food grade request, before feeding into the filter presses, the fermentation liquors can not mix with the flocculant, so all the particles have to be blocked by the filter cloths directly, which requires the filter cloth with very high of density and strong enough for press filters.

Zonel Filtech accumulated abundant experiences in industrial filtrations, such as Mining industries including ore dressing and tailing processing; Fine chemical industries including chemical solution filtration and wastewater treatment; Municipal sewage treatment/ slurry dewatering; Ferrous and non-ferrous metallurgy wastewater treatment; electrolysis metal production, etc; Food and pharmaceutical industries(such as the filter fabric for sugar industries, etc); Building materials and ceramic industries; Dying industries, etc.

All of these industries will equip filter machines such as filter presses, belt filters, disc and pan filters, centrifuge filters, drum filters, etc. According to the requirements combined with the properties of the material that needs to be filtered, Zonel Filtech developed various kinds of filter fabrics to meet our client’s requirements, mainly have 4 series, i.e. polyester filter fabrics, polypropylene filter fabrics, polyamide filter fabrics, and cotton / poly-cotton filter fabrics. If any help is needed, welcome to send us the inquiry.