Home » Liquid Filter

Liquid Filter

Categories

When daily operating the bag filter housing, we may face following of problems: When the micron rate need to be absolute grade, then the flow volume of the filter bag will reduce sharply, also the price of the filter bag will increase much; When the flow volume increased some but we don’t want to change the filter housing, then resistance of the filter bags will be much higher, and maintenance works will increase sharply and cause some more problems, then the pleated filter bags or high flow volume filter cartridges for SS bag filter housing was developed to help to solve the relevant problems and brings the good performance.

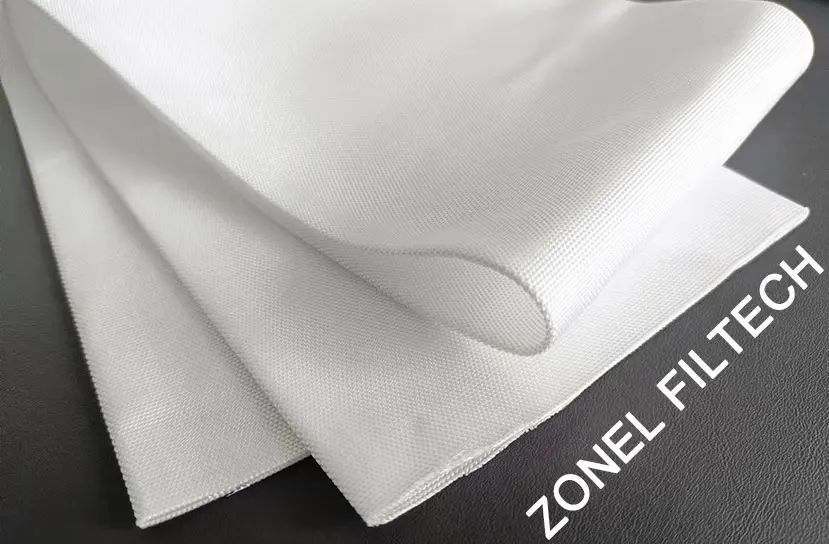

For the traditionally designed nonwoven liquid filter bags, as usual, the filter efficiency is around 60~70%, which just can be used for some primary filtration, but for some high-efficiency request occasions is not applicable.

To break this limitation and offer higher efficiency but economical solutions, Zonel Filtech developed the PPA high-efficiency liquid filter bags which is pushing the boundaries of bag filtration technology far beyond traditional designs. The filter bag with a filter efficiency more than 99%, in some measure, we call it an absolute rated filter bag.

The Zonel brand PPA absolute filter bags adopted the micro PP fiber material with multi-layers made of different density/workmanship filter materials and then put them according to the certain order so as to make the filter bags with different micron sizes and can get the higher filter efficiency as requested to accompany with end users liquid filter housings for various applications.

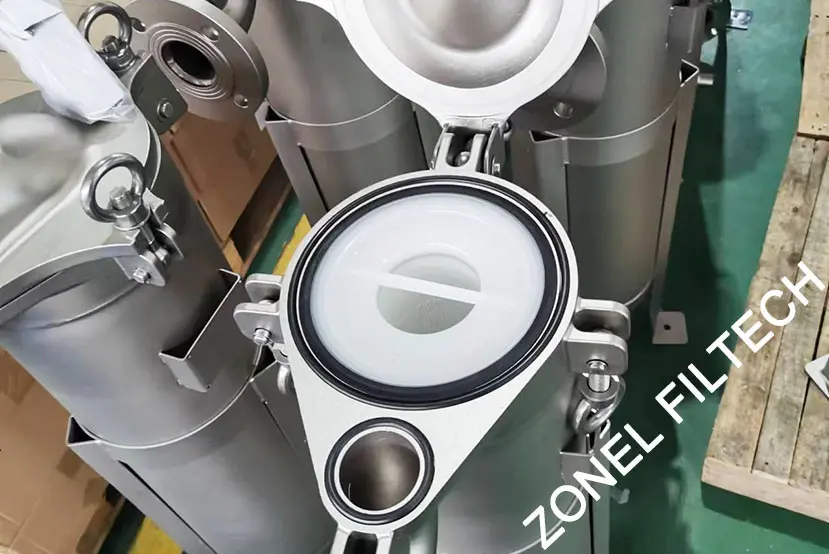

The Candle filter from Zonel Filtech is a kind of pressure filter, the feeding port is from the lower side of the filter vessel, the solid particles are collected at the surface of the filter element and the filtrate goes out from the inner core of the filter element to filtrate tank. The operating procedures include: solution feeding, initial filtrate recycling, filtrate quality checking, filtration, cake washing and air blowing squeezing, and reverse air blowing cake release, if the particle’s specific gravity is higher, the bottom side of the vessel may accumulate the slurry, then bottom size may design with filter board to help dry the slurry and help to handle the residual well.

Candle filter sleeves/ filter hose play a key role in daily production, so adopting suitable filter sleeves will affect the production works directly. Candle filter duct/ filter hose can be designed with both nonwoven and woven type, due to the regeneration issue, the woven filter sleeves are adopted more. Zonel Filtech provides candle filter sleeves in various sizes and materials, any help we can do, welcome to contact us!

The SS cartridge filter housing from Zonel Filtech mostly comes with a multi-cartridge designed SS filter housing, which is combined with stainless steel vessel and liquid filter cartridges or air/steam filter cartridges, the solution/airflow direction is from outside to the inner side of the filter cartridges, the filtrate flow out from the inner core of the filter cartridges and the solid particles will be collected at the surface of the filter cartridges.

Filter fabric, filter fabric for filter press, filter press fabric for volatile slurry, corrosive filter press fabric, high pressure filter fabric, rubber coated filter fabric, edge coated filter fabric, edge sealing filter fabric, high sealing filter cloth

Mostly the raw materials for sugar production will be sugar cane and sugar beet, according to the different clarify methods, which can be divided into carbonized sugar (lime+CO2) and sulfurized sugar (lime+SO2) sugar, though the carbonized sugar is more complex and needs much investment on the machines and Clariant, but the general processing principle and procedures are similar. And the filtering process will be requested for sugar slime concentrating after the clarification, sugar juice filtration (after CO2 insert), syrup purification, crystal dewatering processing (centrifuge filters), and wastewater processing, such as sugar cane and sugar beet washing water processing, filter fabric washing water processing, sediment dewatering processing, etc. The filter machine can be filter presses, vacuum belt filters, vacuum drum filters, centrifuge filters, etc. Zonel Filtech is the top expert who can offer full solutions for filter processing for sugar plants, any help needed, please feel free to contact us!

Zonel Filtech provides replacement filter belts for various filter machines, such as horizontal vacuum belt filters (offer vacuum filter belts), belt filter press (offer press filter belt), HVPF belt filters (tower belt filter), drum filters, paper or nonwoven forming machine, etc.

The filter belt can be produced with woven filter fabric belt and nonwoven needle felt filter belt, mainly applied for paper or nonwoven forming (forming mesh belt), juice squeezing (juice squeezing belt), as well as the general sludge dewatering for municipal sewage treatment, coaling washing slurry dewatering, red mud dehydration from the alumina industry, potash fertilizer production, phosphoric acid production, desulphurization gypsum dewatering, etc.

The woven filter belt (filter cloth belt, filter mesh belt) from Zonel Filtech adopted the optimized PET/ PP/ PA monofilament, multifilament, as well as the spun yarn then combined with various weaving patterns and sound finish treatments so as to meet the various filtration requirements for different applications and make them always keep the stable and good filtration performance.

Besides the filter press fabrics and service, Zonel Filtech also can suggest and supply the filter presses according to clients’ solution content and processing circumstances so as to get the best filtration performance but the most economical investment, the filter presses can be frame plate filter press, chamber filter press and membrane filter press, which can be designed to total automatic so as to get the simplest way and shortest time to operate.

Especially the breakthrough in TPE diaphragm technology, filter presses from Zonel with the properties of endurable, stable, universalizable, and widely used in various industries.

Variable filter chamber technology is widely applied on solid-liquid separation in many industries such as chemical, pharmacy, mining, and so on which help to reduce the water content of the filter cake and extremely improved the production efficiency for our clients.

High flow filter cartridge is one of the main products from Zonel Filtech, which is a kind of pleated filter cartridge with crescent shape pleat geometry, combined with the properties of larger diameter and core-less so as to maximize the filter area, which make the filter cartridge can be operated in the high flow volume and with the much bigger dirty loading capacity, much lower the initial resistance, durable.

Zonel Filtech provides the full range of the replacement high flow filter cartridges of 3M Cuno High Flow series cartridges, Pall Ultipleat High Flow series, Parker ParMax SELECT high flow Filter Cartridges series, Pentair Aqualine high flow water filter cartridge series, etc.

Special requirements can be customized!

HFC series high-flow cartridge filter housing adopted the high-flow filter cartridges instead of the traditional PP melt-blown filter cartridge, the flow volume per single cartridge can be up to 50 CBM per hour. Generally, 1 pcs of 40inches high flow filter cartridges equal to 20 pcs of melt-blown PP filter cartridges with the same length, that’s means the filter housing can be designed smaller, and much more convenient for maintenance work, also can get a much more economical filtration solution of course.

Besides the S.S. filter houses, Zonel Filtech also provides various replacement filter cartridges for liquid filtration, the micron size, materials, product size, and connections of the liquid filter cartridges all can be customized according to different usages.

The micron-rated liquid filter cartridge from Zonel Filtech mainly includes PP melt blown filter cartridge series (spun bonded / thermal bonded filter cartridge); phenolic resin bonded filter cartridge, the string wound filter cartridge series (including PP string wound filter cartridge, bleached cotton string wound filter cartridge, fiberglass string wound filter cartridge); the micro pleated filter cartridge series; big flow filter cartridge series.

The liquid filter cartridges from Zonel Filtech are mainly used for pre-filtration of RO, food & beverage filtration, chemicals filtration, pharmaceutical material purification, organic solvent filtration, etc.

If any liquid filtration cartridges are needed, you are welcome to contact Zonel Filtech!