Woven Filter Fabrics / Filter Cloth / Filter Press Cloth

Zonel Filtech accumulated abundant experiences in industrial filtrations, such as Mining industries including ore dressing and tailing processing; Fine chemical industries including chemical solution filtration and wastewater treatment; Municipal sewage treatment/ slurry dewatering; Ferrous and non-ferrous metallurgy wastewater treatment; electrolysis metal production, etc; Food and pharmaceutical industries(such as the filter fabric for sugar industries, etc); Building materials and ceramic industries; Dying industries, etc.

All of these industries will equip filter machines such as filter presses, belt filters, disc and pan filters, centrifuge filters, drum filters, etc. According to the requirements combined with the properties of the material that needs to be filtered, Zonel Filtech developed various kinds of filter fabrics to meet our client’s requirements, mainly have 4 series, i.e. polyester filter fabrics, polypropylene filter fabrics, polyamide filter fabrics, and cotton / poly-cotton filter fabrics. If any help is needed, welcome to send us the inquiry.

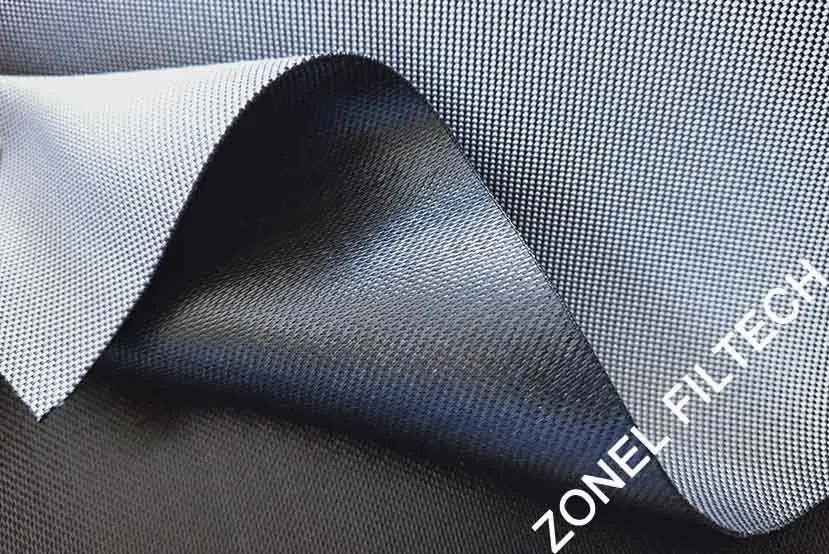

PET woven filter cloth

General introduction: The polyester woven filter fabric from Zonel Filtech adopts first-grade polyester raw materials including polyester spun yarn, polyester multi-filament, polyester mono-filament, and their blended materials, with various patterns to meet the special filtration performance.

Polyester woven filter fabrics can be offered by filter cloth rolls, readymade filter fabrics, or seamless filter sleeves, which are subject to the client’s requirements.

Properties: good for acid resistance, good for oxidant resistance, high tensile strength, excellent abrasion resistance, and food grade.

Applications: for Liquid-solid separation. Zonel also developed some seamless filter sleeves for dust collection. Mainly used in the food and beverage industry, pharmaceutical industry, non-ferrous metallurgy, chemical plant, building section and mining industry, etc, for the equipment of filter presses, centrifuge filters, vacuum filters, pan filters disc filters, belt filters, etc.

We can customize the filter cloth according to the given material.

The typical parameters:

Series | Modelnumber | Density (warp/weft)(counts/10cm) | Weight (g/sq.m) | Burstingstrength (warp/weft)(N/50mm) | Airpermeability (L/sqm.S) @200pa | Construction (T=twill; S=satin; P=plain)(O=others) |

Polyester staple fiber filter cloth series | 740 | 307/206 | 330 | 2800/1700 | 120 | S |

F903 | 286/202 | 370 | 2450/1800 | 130 | S (anti-static) | |

208 | 260/276 | 400 | 2400/1900 | 220 | T + terry finish treatment | |

3927 | 156/106 | 535 | 3900/2600 | 18 | P | |

822 | 260/102 | 940 | 5000/3200 | 22 | T | |

Polyester filament filter cloth series | 240 | 228/184 | 220 | 2350/920 | 80 | P |

621A | 193/130 | 340 | 2900/1950 | 55 | P | |

5124 | 200/94 | 510 | > 5000/2600 | 45 | T | |

3010 | 150/80 | 620 | 4800/4200 | 45 | P | |

F8432 | 331/126 | 760 | > 5000/5000 | 40~50 | T (anti-static) | |

Polyester monofilament filter cloth series | 7033 | 708/260 | 330 | 2670/1300 | 900 | S |

7322 | 515/200 | 390 | 3000/1400 | 1100 | S | |

3415 | 330/165 | 490 | 2800/1500 | 280 | T | |

2227 | 220/263 | 590 | > 5000/5000 | 145 | O | |

5953 | 590/531 | 665 | > 5000/5000 | 45 | O |

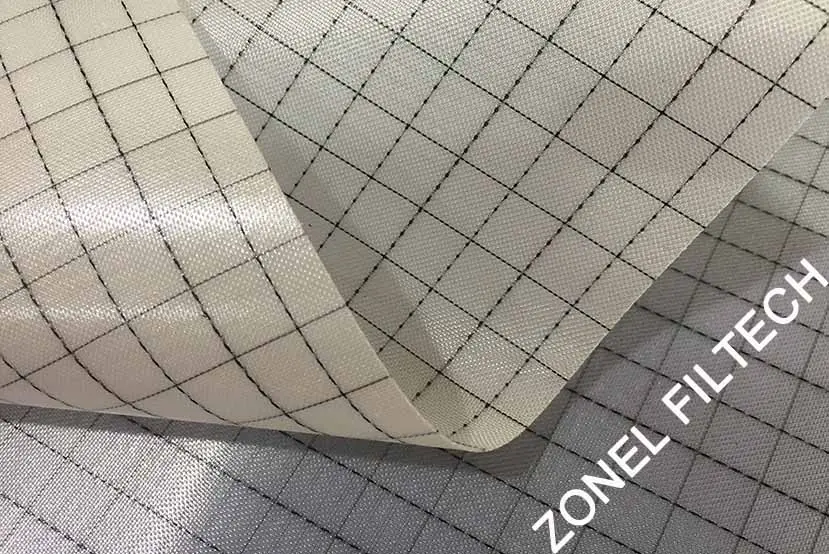

PP woven filter fabrics

General introduction: The polypropylene (PP) woven filter fabric from Zonel Filtech adopted various types of material including PP spun yarn, PP multifilament, PP monofilament, as well as tear film, etc. The material and pattern are chosen according to the special usages so as to make them with perfect performance when filtration.

The PP filter fabrics can be offered by filter cloth rolls, or readymade filter fabrics/filter bags.

Properties: good for acid and alkali resistance, the suitable PH value can be 1~14; with good tensile strength and abrasion resistance, non-toxic, nearly used in all of industrial filtration occasions.

Applications: For slurry dewater or solid particles concentrating. Mainly used for the industries of:

Non-ferrous metallurgy;

Chemicals;

Mining: such as the filter fabric for Kaolin processing, Ore dressing, tailing processing, etc;

Food and beverage industry: such as the filter fabrics for yeast production, filter fabrics for sugar plants, etc; pharmaceutical industry, etc;

The filter fabric installed in the equipment such as filter presses, centrifuge filters, vacuum filters, pan filters, disc filters, belt filters, drum filters, etc.

We can customize the filter cloth according to the given material.

The typical parameters:

Series | Modelnumber | Density (warp/weft)(counts/10cm) | Weight (g/sq.m) | Burstingstrength (warp/weft)(N/50mm) | Airpermeability (L/sqm.S) @200pa | Construction (T=twill; S=satin; P=plain)(O=others) |

Polyester staple fiber filter cloth series | 4131 | 161/122 | 315 | 1550/1100 | 35 | P |

4212 | 236/114 | 390 | 3500/2100 | 170 | T+terry finish | |

2316 | 232/60 | 400 | 3050/600 | 120 | S | |

1140 | 433/157 | 425 | 4200/1200 | 45 | S+terry finish | |

2402 | 236/118 | 530 | 4800/2300 | 110 | T | |

Polyester filament filter cloth series | B6840 | 268/157 | 495 | 4500/3800 | 75 | T |

5422 | 535/220 | 570 | 5000/1650 | 15 | O | |

1058 | 413/228 | 590 | 5000/3100 | 75 | O | |

10828 | 425/110 | 640 | >5000/2100 | 28 | O | |

9963 | 389/248 | 690 | >5000/3000 | 15 | O | |

Polyester monofilament filter cloth series | 3130 | 427/220 | 250 | 2550/1250 | 560 | T |

1382 | 425/169 | 290 | 3150/1400 | 100 | S (mono-multi) | |

5744 | 1134/400 | 310 | 4500/2200 | 90 | O | |

6022 | 630/214 | 326 | 3250/2350 | 110 | S (mono-multi) | |

12870C | 625/216 | 480 | 3500/2700 | 110 | O (double layer) |

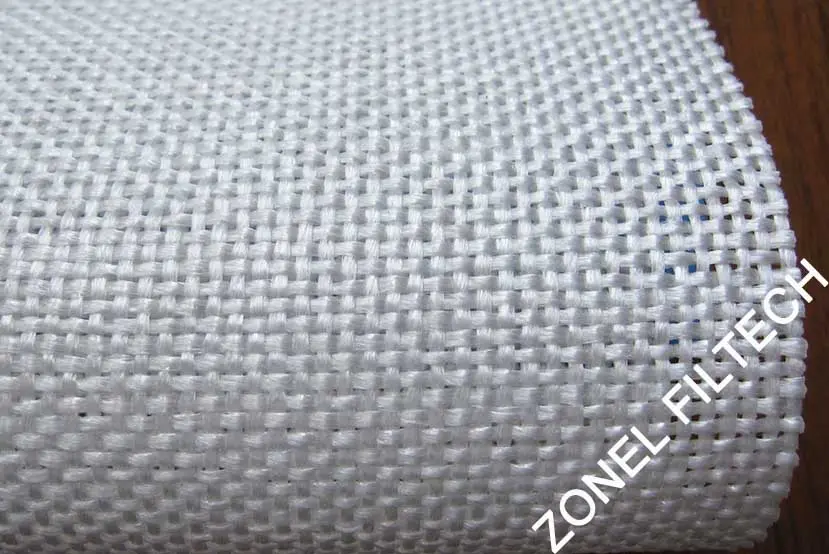

PA woven filter fabrics

General introduction: polyamide (PA) or Nylon material with the properties of abrasion resistance and super tensile strength is born to be an excellent material for filter fabrics production. The PA/nylon filter cloth from Zonel Filtech are divided into multifilament filter fabrics and monofilament filter fabrics series, which will be suggested to end users according to different working circumstances.

The PA filter fabrics can be offered by filter cloth rolls, or readymade filter fabrics/filter bags according to the client’s requirements.

Properties: weak acid resistance, good alkali resistance, high tensile strength, mainly used for circumstances where with tough occasions, such as for mining with heavy duties, or rough particles that need filter cloth with good abrasion resistance, etc.

Applications: For slurry dewater or solid particles concentrating. Mainly used for the industries of mining (ore dressing or tailing processing, coal washing, etc), chemical, ferrous and non-ferrous metallurgy, etc.

The filter fabric installed in the equipment such as filter presses, centrifuge filters, vacuum filters, pan filters, disc filters, belt filters, drum filters, etc.

We can customize the filter cloth according to the given material.

The typical parameters:

Series | Model number | Density (warp/weft) (counts/10cm) | Weight (g/sq.m) | Bursting strength (warp/weft) (N/50mm) | Air permeability (L/sqm.S) @200pa | Construction (T=twill;S=satin;P=plain) (O=others) |

Polyamide (Nylon) filament filter cloth series | 301 | 275/250 | 106 | 2010/1980 | 114 | P |

663 | 192/140 | 264 | 2300/1940 | 28 | P | |

636 | 244/122 | 390 | 4600/2200 | 45 | P | |

856 | 306/133 | 450 | 4800/3200 | 220 | T | |

9447 | 370/181 | 475 | 4300/3500 | 150 | T | |

Polyamide (Nylon) monofilament filter cloth series | 2325 | 472/224 | 340 | 2600/2200 | 950 | S |

2322 | 472/224 | 355 | 2400/2100 | 650 | S | |

F2327 | 531/212 | 370 | 2400/2500 | 850 | S (anti-static) | |

5542 | 550/114 | 430 | 3600/2000 | 1500 | T | |

2475 | 945/295 | 615 | >5000/2300 | 350 | O |

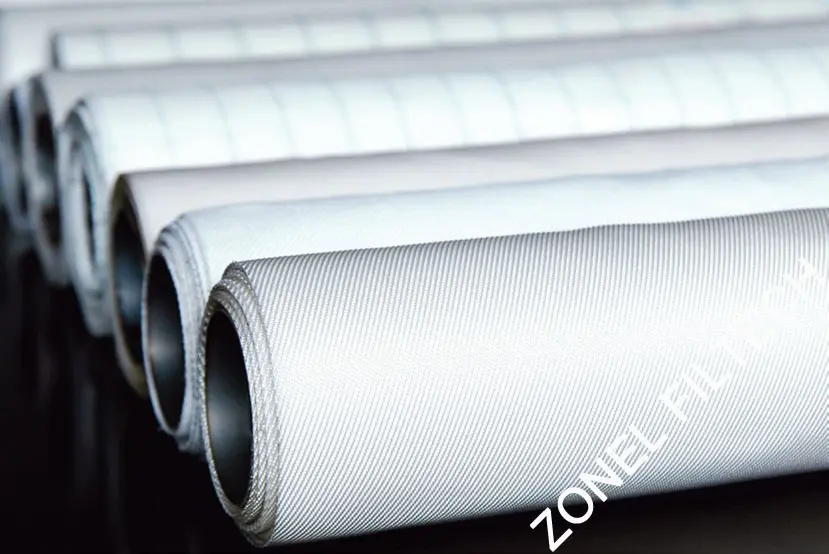

Cotton/poly-cotton Filter Fabrics

Zonel Filtech provides polyester/cotton fabrics which is special designed for electrolytic industries and adopted as diaphragm bags(such as diaphragm bags for electrolytic Nickel plants), the fabrics adopted well-chosen polyester-cotton yarn, then woven by top-ranking heavy-duty rapier looms, after the special finish treatment, with the properties of high tensile strength, equal permeability, low resistance, high electrolytic efficiency, good acid and alkali resistance, easy install, longer service life.

The typical parameters:

Series | Model number | Density (warp/weft) (counts/lOcm) | Weight (g/sq.m) | Bursting strength (warp/weft) (N/50mm) | Air permeability (L/sqm.S) @200pa | Construction (T=twill;S=satin;P=plain) (O=others) |

Poly-Cotton Series | 3950 | 152/98 | 780 | 4500/2800 | <10 | Hight tensile strength, Low perbility |

9898 | 228/149 | 1080 | 5000/3000 | <10 | Hight tensile strength, Low perbility |