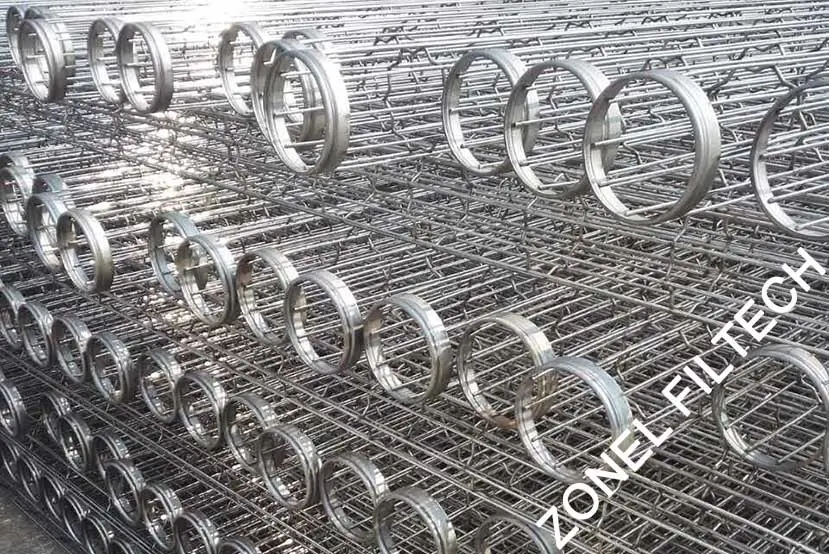

Filter Bag Cage/ Filter Bag Supporting Cage/ Filter Bag Frame

When the pulse jet bag filter house operates, the dust air always comes from outside of the filter bags and the purified air will pass through the filter bags and then exhaust into the atmosphere, during that time bag filter house always with a positive or negative pressure, so a filter bag cage will be put inside of the filter bag to anti-collapse.

The filter cage also called dust collector filter cage or filter bag frame, can be made of galvanized steel, carbon steel with silicon coating, SS 304 or SS316, titanium, and so on for different working conditions.

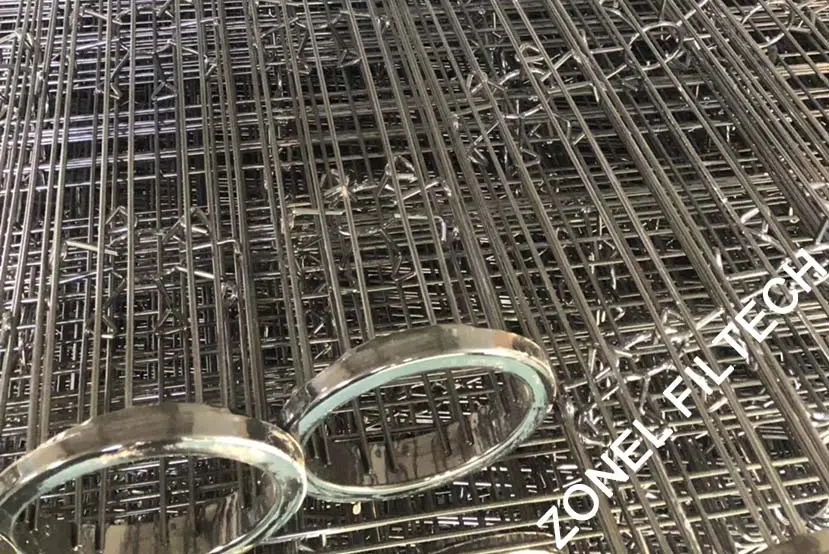

The filter bag support cage was combined with vertical wires, supporting cages, top caps, and bottom caps, as well as the venturi. To reduce the filter bags’ touch with the supporting rings of the bag supporting cage, we developed the star-shaped side view dust collector filter bag cage; to increase the filter area, we developed the pleated filter bags with the relevant pleated filter bag cages.

General introduction for filter bag cage/ Filter bag supporting cage/ Filter bag frame

When the pulse jet bag filter house operates, the dust air always comes from outside of the filter bags and the purified air will passes through the inner side of the filter bags and then exhausts into the atmosphere, and bag filter house always with a positive or negative pressure, so in case the filter bag collapse, we always insert a metal filter bag cage into the filter bags.

The filter cage also called a dust collector filter cage or filter bag frame, can be made of galvanized steel, carbon steel with silicon coating, SS 304 or SS316, even titanium, and so on for different working conditions. According to the filter bag shape, the bag house filter cage also can be designed with a side view of round-shaped bag supporting cages, oval-shaped bag cages, etc.

The filter bag support cage was combined with vertical wires, supporting cages, top cap, and bottom caps, as well as the venturi to the pressed purging air leading. To reduce the filter bags’ touch with the supporting rings of the bag cage to make the filter bags broken, we developed the star-shaped side view dust collector filter bag cage/ star ring filter bag cage; to increase the filter area, sometimes also design the filter bag with pleated design, so Zonel Filtech also developed the good quality pleated filter bag cages as requested.

Properties of filter bag cages from Zonel Filtech

1. Zonel Filtech always designs the filter bag cage according to the different filter bags used, also helps to choose the suitable filter bag cages according to different working conditions, such as temperature, corrosive situation, dust with explosive or not, etc.

2. The material adopted the well-treated steel wire, strong and with good elasticity, and smooth surface.

3. The filter bag cage is strongly welded, and won’t be broken from the welding point for normal operation; the top side welding from the inner side, won’t touch with the filter bags and won’t break the filter bag.

4. The venturi with well designed, and can lead pressed air to purge the filter bag efficiently but won’t hurt the filter bag.

5. The surface of the filter bag supporting cage can be treated with galvanized, organic silicon coated, and so on as requested.

6. Various material is available, such as carbon steel, SS304, SS316L, Titanium, etc.

7. The filter bag frame is available for all kinds of the filter bags, such as round filter bags, oval-shaped filter bags, pleated filter bags, etc.

8. The dust collector filter bag cage from zonal fintech can be designed with single pcs or multi-pieces combined style so as convenient to install.

Typical technical data of the dust filter bag cage from Zonel Filtech

Diameter (mm) | Sugg. Max length (mm) | Vertical wire number (pcs) | Material | Length of Venturi (mm) | |

Chemical fiber bag | Fiber glass bag | ||||

115 | 7000 | 8 | 16 | Gl, MS, SS304&316, Ti | 140 |

120 | 7000 | 8 | 16 | Gl, MS, SS304&316, Ti | 140 |

125 | 7500 | 10 | 20 | Gl, MS, SS304&316, Ti | 140 |

130 | 7500 | 10 | 20 | Gl, MS, SS304&316, Ti | 140 |

135 | 8000 | 10 | 20 | Gl, MS, SS304&316, Ti | 140 |

140 | 8000 | 10 | 20 | Gl, MS, SS304&316, Ti | 140 |

145 | 9000 | 12 | 20 | Gl, MS, SS304&316, Ti | 150 |

150 | 9000 | 12 | 24 | Gl, MS, SS304&316, Ti | 150 |

155 | 9500 | 12 | 24 | Gl, MS, SS304&316, Ti | 150 |

160 | 9500 | 12 | 24 | Gl, MS, SS304&316, Ti | 150 |

165 | 10000 | 12 | 24 | Gl, MS, SS304&316, Ti | 150 |

The applications of the filter bag cage

The filter cage is mainly used for the filter bag anti-collapse, or as filter bag supporting cages of pulse jet bag filter housing/dust collectors.

Any help is needed, welcome to contact Zonel Filtech!