Filter bags are essential components in numerous industrial processes, serving as critical tools in the filtration and purification of air and liquids. The longevity of these filter bags is vital not only for maintaining high-quality outputs but also for reducing both operational costs and environmental impact. This article explores effective strategies and best practices for extending the service life of filter bags, thereby enhancing their efficiency and overall performance.

Table of Contents

ToggleUnderstanding Filter Bag Functionality

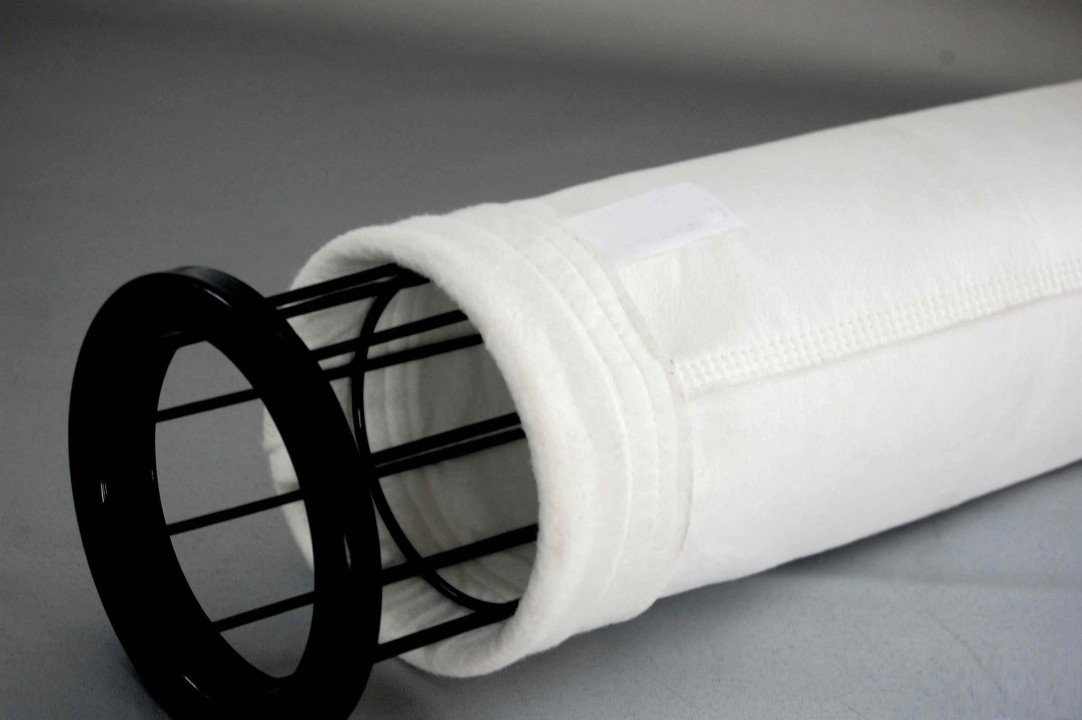

Filter bags work by trapping particulates within their fibers while allowing air or liquid to pass through. The materials used in filter bags can vary—ranging from natural fibers like cotton to synthetic materials like polyester or polypropylene—each selected based on its compatibility with the substances being filtered and the conditions of the operating environment.

Key Strategies for Extending Filter Bag Life

Proper Selection of Filter Media:

The initial step to guarantee the durability of a filter bag is selecting the appropriate filter media. This decision should be based on the specific requirements of the application, including the type of particulates being filtered, chemical compatibility, temperature resistance, and required filtration efficiency. For example, polypropylene might be favored for its chemical resistance and suitability for lower temperatures, whereas nomex might be chosen for high-temperature applications.

Optimal Configuration and Installation:

Proper installation of filter bags is essential to maximize their lifespan. This includes ensuring that bags are correctly seated and that all seals are intact to prevent bypass and uneven filtration loads. Proper installation helps avoid physical damage during operation and ensures that the bags perform efficiently.

Routine Inspections and Maintenance:

Frequent inspections are crucial to detect wear and tear early, helping to avoid catastrophic failures. Visual inspections can identify issues such as tears, holes, and abrasions, while performance monitoring can detect drops in efficiency that may indicate clogging or saturation. Scheduled maintenance, including cleaning and replacing parts like seals and gaskets, also plays a critical role in extending the life of filter bags.

Employing Pulsed or Reverse Air Cleaning Techniques:

For systems equipped with pulse-jet or reverse air cleaning mechanisms, optimizing the cleaning cycles can significantly extend filter life. These cleaning methods help remove particulate build-up on the filter surface, enhancing airflow and preventing material penetration that can lead to fiber degradation. Adjusting the pulse timing and duration based on differential pressure readings can optimize cleaning efficiency without over-stressing the fabric.

Managing Air-to-Cloth Ratio:

The air-to-cloth ratio, which refers to the volume of air or gas passing through a given area of fabric, is a critical parameter in filter bag applications. Overloading the bags can lead to increased pressure drop, higher emissions, and faster degradation of the filter media. Keeping the air-to-cloth ratio within ideal parameters ensures that the bags can handle the particulate load without excessive stress.

Environmental and Operational Considerations

- Controlling Process Conditions:

Stabilizing process conditions such as temperature, pressure, and chemical exposure can prolong filter bag life. Extreme conditions can degrade materials quicker and cause failures. Implementing controls to stabilize these variables can significantly benefit the durability of the filter bags.

- Using Protective Coatings and Finishes:

Applying protective coatings and finishes can enhance the physical properties of filter bags. Treatments such as water repellents, antistatic coatings, and fire retardants can protect against environmental factors that might otherwise accelerate wear and tear.

Conclusion

Extending the service life of filter bags is crucial for optimizing industrial operations both economically and environmentally. Through careful selection of materials, proper installation and configuration, routine maintenance, and the management of operating conditions, the longevity and efficiency of filter bags can be significantly improved. These practices not only reduce the need for frequent replacements but also contribute to smoother, more reliable production processes. As industries continue to evolve and seek more sustainable operations, the focus on prolonging the life of essential components like filter bags will undoubtedly intensify, reinforcing the importance of these strategies in industrial efficiency.