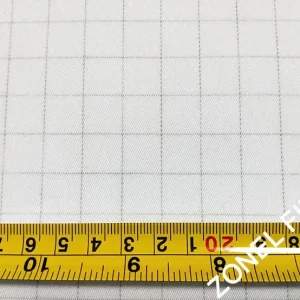

High Temperature Resistance Dust Filter Material

High temperature resistance filter media from Zonel Filtech which is a needle felt filter material series for dust collection. The series is suitable for the operating circumstance with the continuous temperature not exceed 260 degree centigrade and the maximum instant temperature not exceeding 280-degree centigrade, during the temperature area, Zonel Filtech can help you to define the most suitable filter material for your dust bag filter houses.

Zonel Filtech can provide both needle felt filter cloth rolls and ready-made filter bags, the material include: Polyimide (P84) needle-felt filter cloth and filter bags with various finish treatments; PTFE needle-felt filter cloth and filter bag with various finish treatments; Fiber glass filter felt or fiber glass blended filter felt with various finish treatments.

Any help needed from Zonel Filtech, just feel free to send the inquiry.

Polyimide (P84) needle felt for dust collector systems

General introduction of the Polyimide (P84, PI) needle-felt filter cloth:

P84(PI-polyimide) fiber with the properties of high-temperature resistance and inflammable, the tri-leaf structure of the fiber help the polyimide needle felt filter cloth with a much lager filter surface when compare to the filter cloth with the other fibers, so the P84 filter cloth is a perfect material and it always can meet very good filter efficiency.

Relevant specifications for the P84 needle felt:

Material: P84(PI-polyimide) fiber, supported with P84(PI-polyimide) / PTFE scrim

Weight:450~650g/sq.m

Operation Temperature: Continues: ≤240℃; Peaks: 260℃

Surface treatment available: singed & glazed, heat set, PTFE suspension bath, PTFE membrane.

We can customize the products according to the requirements of the clients!

The properties of the polyimide dust filter bags:

1. High temperature resistance:

Recommended continuous operation temperature: ≤240 degrees C; instant peaks: 260 degrees C.

2. Stable size under high temperature after heat setting treatment: at 260 degrees C, the shrinkage does not exceed 1%.

3. Fireproof.

4. Good abrasion and folding resistance.

5. High filter efficiency and long service life.

Main applications of the P84(PI-polyimide) filter bags:

Mainly used for Cement kilns, Asphalt, Waste incinerators, coal boilers, etc.

Note:

1. Special specifications can be customized.

2. maximum width:2.25meters.

3. both filter cloth rolls and filter bags are available to supply from Zonel Filtech.

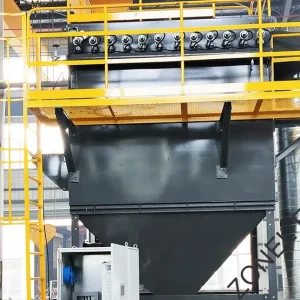

Fiberglass needle felt for dust collector systems

General introduction of the fiber glass needle felt filter cloth and blended filter material:

Fiber glass needles felt after some reasonable finish treatment as a kind of filter cloth that can be used in some extremely high-temperature circumstance for dust collection.

For conquer the disadvantages of weak cohesive, poor folding resistance and wearing of fiber glass nonwoven filter material, ZONEL FITLECH developed some new style filter cloths based on glass fiber (similar to FMS, we called fiberglass blending needle felt filter cloth), after several decades testing, the fiber glass filter bag and the fiber glass blended filter bags are working excellent in our clients’ bag filter houses.

Relevant specifications of the glass fiber felt filter cloth and blended filter material:

Material: glass fiber + high-temperature resistance fiber such as Aramid (Nomex), PPS, P84, PTFE, etc + glass filament

Weight: > 880 g/sq.m

Tensile strength: Warp :> 1800 N/5cm; Weft :> 1800 N/5cm

Service Temperature: Continues: <260℃; Peaks: 280℃

Surface treatment for choice: glazed, heat set, PTFE suspension bath, PTFE membrane.

The properties of the fiber glass needle felt filter cloth and blended filter material:

1. High Temperature Resistance: 260-280 degrees C

2. Excellent corrosion resistance (except HF)

3. Customized according to different operation condition, longer service life.

4. Air permeability is higher and more stable and can be operated with a higher air/ cloth ratio (up to 1.0~1.2m/min) when compare to the woven fiber glass filter fabric.

5. Abrasion resistance.

6. with an economical investment.

7. Can be used in a variety of complex and harsh environmental conditions.

Main applications of the fiber glass needle felt filter cloth and blended filter material:

Fiber glass needle felt filter cloth and blended type filter cloth are widely used for dust/ fume removal at the plants such as steel plants, nonferrous smelting works, chemical plants, carbon black production, Asphalt and cement plants, power plants, etc.

Note:

1. Special specifications can be customized.

2. maximum width:2.25meters.

3. both filter cloth rolls and filter bags are available to supply.

If anything more needed, feel free to contact ZONEL FILTECH!

PTFE (polytetrafluoretyhylene, Teflon) needle felt filter cloth

General introduction of the PTFE needle felt filter cloth

PTFE (polytetrafluoretyhylene) also called Teflon, which be treated as the KING of plastics due to its properties of high-temperature resistance, corrosive resistance, and durability, which is an innate excellent material for industrial filtration.

Zonel Filtech adopted the first grade PTFE (Teflon) fiber and sound workmanship needle punched into felt, after the special finish treatment, the Teflon needle felt filter cloth can be widely used in various industrial occasions for dust collection (PTFE dust filter bag ) and liquid filtration (Teflon micron rated filter bag ).

Relevant specification for the PTFE (polytetrafluorethylene, Teflon) needle felt:

Material: 100% PTFE (polytetrafluorethylene, Teflon) fiber, supported with PTFE (polytetrafluorethylene, Teflon) filament scrim

Weight:750~800 g/sq.m

Operation Temperature: Continues: ≤260℃; Peaks: 280℃

Surface treatment available: singed & glazed, heat set, PTFE suspension bath, PTFE membrane, micro pore size surface treatment.

We can customize the products according to the requirements of the clients!

The properties of the Teflon dust filter bags (made of PTFE filter cloth )

1. High-temperature resistance, continuous operation temperature can be up to 260 degrees C, and instant operation can be up to 280 degrees C.

2. Large-scale production is available, with a much cheaper price when compared to the before.

3. Can be used at full PH range.

4. Long service life, as usual, can be more than 4 years.

5. All of the production ranges with various usage are available.

Main applications of the PTFE filter bags:

PTFE filter cloth is a special material with good alkali and acid resistance, anti-hydrolysis, and stable physical dimension, mainly used in coal burning boilers, waste incineration, carbon black producing, Tio2 producing for fume removal or dust collection (PTFE dust filter bag), as well as some high temperature or some corrosive liquid filtration(PTFE liquid filter bag).

Note:

1. Special specifications can be customized.

2. maximum width:2.25meters.

3. both filter cloth rolls and filter bags are available to supply.