Home » Dust Filter

Dust Filter

Categories

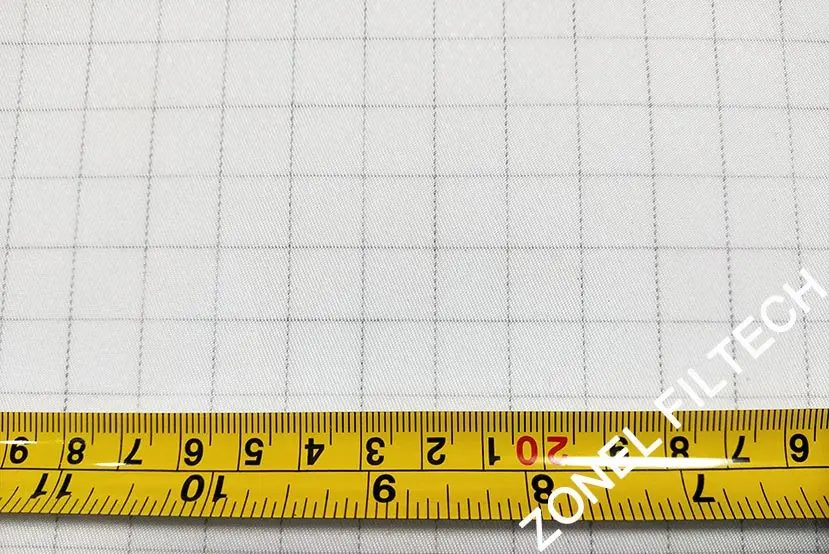

Zonel Filtech developed the anti-static filter fabrics for fluid bed dust collection application.

The filter fabric adopted the food grade raw materials, with special woven construction and finish treatment, suitable for the particle size between 0.5~50 micron particles collection, surface electrical resistance not exceed 10^6, any help needed, welcome to contact with us!

The anti-static filter cloths from Zonel Filtech were designed for dust collection (anti-static dust filter bags) in the occasion of dust air with some flammable or explosive materials, such as flour dust, aluminum dust, coal dust, and some explosive powder materials in the industries such as chemical, etc.

As we know, when the density of the flammable dust to a certain point, a small spark may cause an explosion and fire, so when we design the filter materials we have to take them into the consideration.

Zonel Filtech designed the anti-static needle felt filter cloth series according to different applications. Include wire line anti-static needle felt, square line anti-static needle felt, conductive fiber blended needle felt filter cloth (include S.S. fiber blended needle felt filter cloth, modified conductive polyester anti-static needle felt filter cloth), etc. We offer both of anti-static filter cloth rolls and ready-made anti-static filter bags, any help needed, welcome to contact Zonel Filtech!

The Aramid fiber/Meta-aramid fiber for needle felt filter cloth production also called Aramid fiber 1313 in China, and Nomex® is one kind of the aramid fibers produced by Dupont®.

Zonel Filtech adopted the super quality aramid fiber and scrim then well needle punched them into felt, after the sound finish treatment such as singing, calendering, heat setting, water and oil repellent, PTFE membrane laminated, and so on so as to make the filter cloth with the properties of higher tensile strength, abrasion resistance, lower emission, suitable for the sticky/high moisture dust air purifying, easy purging, lower heat shrinkage, etc.

Aramid (Nomex) filter bags mainly operate in the bag filter house with a temperature of between 130 ~ 220 degrees C, a suitable PH value between 5~9, widely used in the steel industry, carbon black industry, building materials industries (cement plants, asphalt mixing station, etc) and power industry, etc.

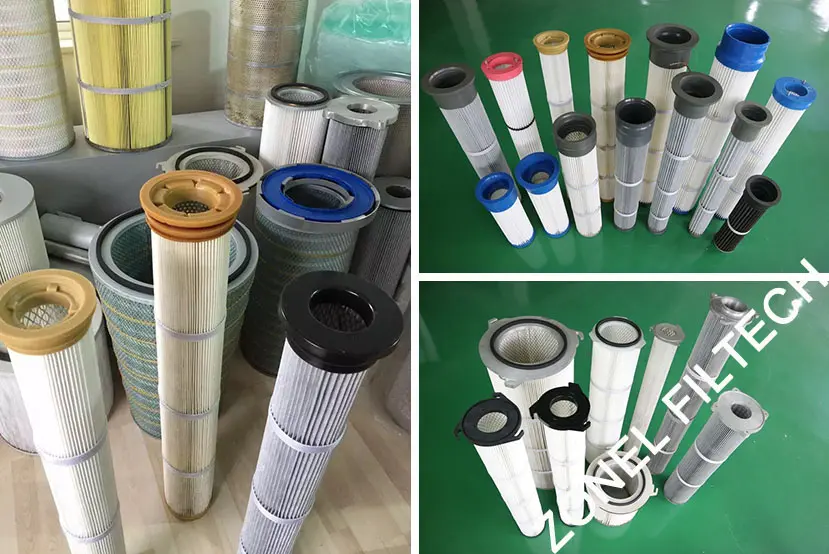

Dust filter cartridges are the key parts of the cartridge dust collectors, according to different systems with the special applications, the cartridge always designed with different caps with the relevant sealing method, different filter material and the glue material, so the professional and experienced supplier will help you to solve all of these kinds of problems in case any possible accident when operating.

Zonel Filtech provide the fully solutions for the replacement filter cartridges nearly for all of the famous brand dust collectors of the world, such as the replacement cartridges for Donaldson® cartridge dust collectors, Nederman® cartridge dust collectors, Amano® cartridge dust collectors, FARR® cartridge dust collectors, Nordson® cartridge dust collectors, etc.

The replacement filter cartridges from Zonel Filtech with the properties of stable and strong construction, big dust load capacity and good air/cloth ratio, long service life, any help needed, welcome to contact us!

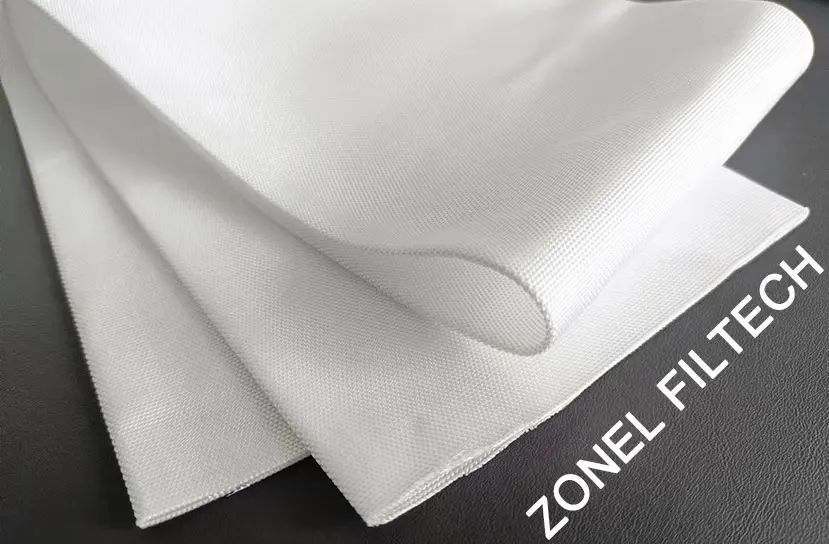

Zonel brand fiberglass filter fabrics are made of E-fiber glass filament/E-fiber glass bulked yarn with some special finish treatment after the weaving works according to the different working conditions to make the glass fiber filter cloth with a much better flexibility, abrasion resistance and also suitable to be used in some special chemical circumstances besides the high temperature so as to prolong the service life of the fiberglass dust filter bags.

Zonel Filtech provides both fiberglass filter fabric rolls and fiberglass ready-made dust filter bags, we also offer free consulting to our clients to help them get the most suitable fiberglass filter bags for their bag filter houses, as well as the relevant filter bag supporting cages for their glass fiber dust filter bags and the accessories of the purging systems, etc.

If any help is needed from Zonel Filtech, just feel free to send the inquiry! Why choose the fiberglass filter bag with PTFE membrane treatment?

Due to the high-temperature resistant chemical fiber filter bags always the extremely high prices which is a heavy burden to the DC operators without doubts for every change. Getting a kind of high-temperature resistant filter bag but with lower cost become to the reality requirement from the filtration market, and fiber glass is the first choice.

The Fiber glass needle felt filter cloth from Zonel Filtech adopted 100% glass fiber, with a sound needle punching and finish treatment, the fiber glass filter bags can be used in some extremely high-temperature occasions for dust collection.

To conquer the disadvantages of weak cohesive, poor folding resistance of the glass fiber felt, ZONEL developed fiber glass blended needle felt(similar to FMS needle felt or FMS filter bag), these fiber glass nonwoven filter materials already with the long time testing, nowadays are widely used for many applications, such as cement, metallurgy, mining, chemical, thermal power plants, etc.

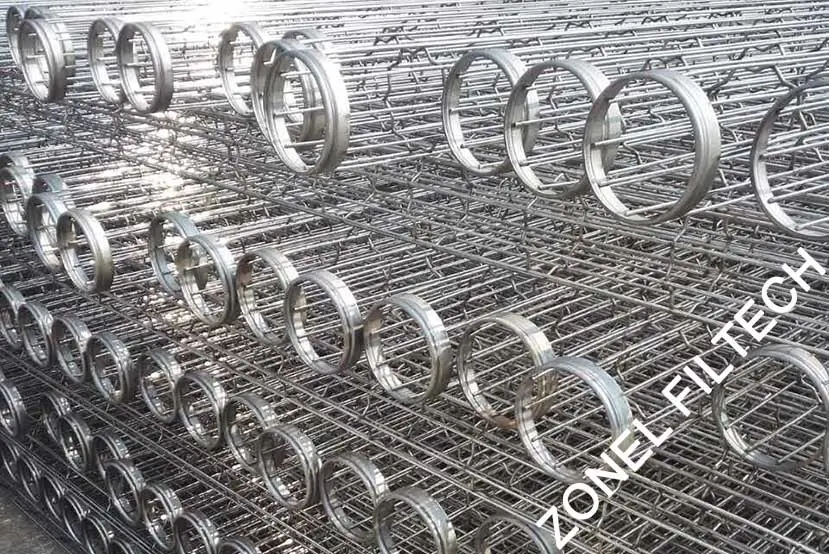

When the pulse jet bag filter house operates, the dust air always comes from outside of the filter bags and the purified air will pass through the filter bags and then exhaust into the atmosphere, during that time bag filter house always with a positive or negative pressure, so a filter bag cage will be put inside of the filter bag to anti-collapse.

The filter cage also called dust collector filter cage or filter bag frame, can be made of galvanized steel, carbon steel with silicon coating, SS 304 or SS316, titanium, and so on for different working conditions.

The filter bag support cage was combined with vertical wires, supporting cages, top caps, and bottom caps, as well as the venturi. To reduce the filter bags’ touch with the supporting rings of the bag supporting cage, we developed the star-shaped side view dust collector filter bag cage; to increase the filter area, we developed the pleated filter bags with the relevant pleated filter bag cages.

The cartridge dust collector with the advanced properties of small size, big air flow volume, high filter efficiency, small investment which are widely used many industrial occasions for dust collection.

Zonel Filtech can provide the oblique installed filter cartridge dust collectors, vertical installed filter cartridge dust collectors, portable dust collector, silo dust collectors, etc.

Besides the dust filter machines, Zonel Filtech also provide replacement filter cartridges for cartridge dust collector for both Zonel made and other OEMs, and special size and usage filter cartridge can be customized.

Welcome to cooperate with Zonel Filtech! (How to choose the suitable cartridge dust collector?)

The gas turbines are widely equipped in thermal power plants of the world, and the premium quality inlet air is crucial for their daily operation and maintenance. For improving the efficiency of the gas turbine and prolong the service life, the upstream filtration is necessary.

High temperature resistance filter media from Zonel Filtech which is a needle felt filter material series for dust collection. The series is suitable for the operating circumstance with the continuous temperature not exceed 260 degree centigrade and the maximum instant temperature not exceeding 280-degree centigrade, during the temperature area, Zonel Filtech can help you to define the most suitable filter material for your dust bag filter houses.

Zonel Filtech can provide both needle felt filter cloth rolls and ready-made filter bags, the material include: Polyimide (P84) needle-felt filter cloth and filter bags with various finish treatments; PTFE needle-felt filter cloth and filter bag with various finish treatments; Fiber glass filter felt or fiber glass blended filter felt with various finish treatments.

Any help needed from Zonel Filtech, just feel free to send the inquiry.

Homo-polymer acrylic needle felt / Acrylic needle felt / polyacrylonitrile needle felt (PAN needle felt filter cloth) well known for its hydrolysis resistance performance, ZONEL FILTECH researched and developed the special PAN filter cloth for dust collection.

The acrylic fiber with customized sizes after the needle punched into the felt, for a perfect performance on filtration, the surface will be treated with water and oil repellent or PTFE membrane laminated, so as to make the filter bags not easy to be blocked and reduce the dust emission, so as to prolong the service life of the filter bags.

The acrylic dust filter bags from Zonel Filtech will adopt the S.S. 304 top rings with the PTFE sewing thread well treated, so good performance will be guaranteed, any help needed from Zonel Filtech, welcome to contact us!

Pocket bag air filters can be made of synthetic pocket bag filter material or pocket synthetic fiber media blended with active carton, as well as the fiber glass pocket bag filter materials with various filter efficiency, mainly from F5~F9 (CRAA 430) or EU5~EU9 (EN779) or MERV9~MERV15 (ASHRAE).

The pocket bag filters are often installed in HVAC systems, so also called HVAC pocket bag air filters, which is designed for industrial and commercial applications as well as for residential use to boost indoor air quality. Sometimes, the pocket bag air can be used for the first stage of the HVAC systems but mostly will be used as a secondary or final filter behind a pleated primary filter.

The pocket bag filter material was adopted the nonwoven filter material with the relevant filter efficiency, to improve the dust loading and reduce the air resistance, the filter pockets will be divided into several small spaces, and all the synthetic material will sealed with heat welding and the fiber glass will be sewn by sewing thread but the seam will be sealed with thermoplastic to guarantee the filter efficiency at the right requested data.