Air slide systems are an essential part of industrial operations, enabling the smooth and efficient transportation of dry, bulk materials. These systems use the power of air to facilitate the flow of fine particles over a slide, eliminating the need for mechanical transportation. With their versatility and energy efficiency, air slide systems are used across various industries, ensuring the reliable handling of powders and granular materials. In this article, we will explore the most common applications of air slide systems, how they function, and the benefits they bring to different sectors.

Table of Contents

ToggleHow Air Slide Systems Work

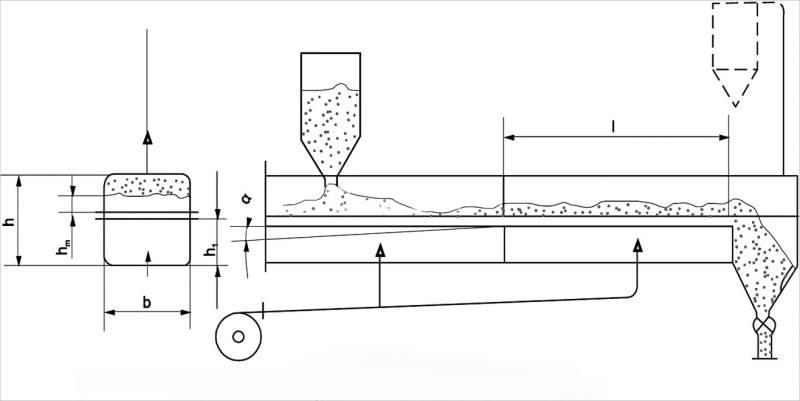

At their core, air slide systems are pneumatic conveyors that rely on gravity and air pressure to move bulk materials. They are made up of a cloth or porous membrane that is positioned inside a closed channel. Compressed air is blown underneath the material through the fabric, reducing the friction between the material and the surface of the slide. This creates a fluidized layer, allowing the material to flow freely down a slight incline, usually at an angle between 6 and 12 degrees.

The effectiveness of air slide systems comes from their ability to transport fine powders like cement, flour, alumina, and other bulk solids. The key benefit is their energy efficiency, as the use of air and gravity minimizes the need for heavy mechanical components such as motors and belts. Let’s now look at their applications in various industries.

Common Applications of Air Slide Systems

Cement Industry

Cement production requires handling large quantities of fine, dry powders such as raw meal, cement, and clinker dust. Air slide systems provide an ideal solution for the pneumatic conveying of these materials between different parts of the production process. They are used in raw material handling, blending, feeding, and storing stages.

- Benefits: Air slide systems prevent the segregation of cement particles, reduce wear on equipment, and ensure a consistent flow rate. They also reduce the need for complex conveyor systems, resulting in lower maintenance and operational costs.

Alumina and Bauxite Industry

In the alumina and bauxite industry, air slide systems are widely used to transport alumina powder from storage silos to the production units. Since alumina is highly abrasive, air slide conveyors are preferred over traditional mechanical conveyors to avoid excessive wear on components.

- Benefits: The use of air slide systems minimizes equipment breakdowns and reduces energy consumption during the transportation of alumina. The smooth transport process also helps maintain the quality of the powder.

Flour and Grain Industry

In food processing, especially in the flour and grain industries, air slide systems play a critical role in transporting bulk grains and flour. Grain processing plants need efficient systems to move large amounts of fine flour and grains from one stage of production to another, such as from milling to packing.

- Benefits: Air slide systems allow for continuous, dust-free transport of grains and flour, ensuring hygiene and preventing contamination. The system also eliminates the need for heavy mechanical belts, which can be prone to contamination.

Chemical Industry

The chemical industry relies on air slide systems for the transport of various fine chemical powders such as carbon black, calcium carbonate, soda ash, and sulfur powder. Many chemical products are sensitive and require careful handling to prevent degradation or reactions.

- Benefits: Air slide systems ensure that powders are moved without the risk of contamination or reaction with other materials. Additionally, they keep agglomerates from forming, which is essential for preserving the consistency and quality of chemical powders.

Pharmaceutical Industry

The pharmaceutical industry uses air slide systems for the conveyance of fine powders used in the production of tablets, capsules, and other drug forms. Since hygiene and contamination control are paramount, air slide systems are an excellent choice due to their enclosed, dust-free design.

- Benefits: Air slide systems help maintain the purity of pharmaceutical powders by minimizing exposure to contaminants. The systems also allow for precise control over material flow, which is essential for ensuring the accuracy of drug formulation.

Mining and Minerals Processing Industry

In the mining and minerals processing sector, air slide systems are used to transport fine materials such as lime, gypsum, and phosphates. The systems are employed in both underground and surface mining operations to ensure the efficient transport of these materials to processing plants.

- Benefits: Air slide systems reduce the need for heavy-duty mechanical conveyors, which are expensive and require more maintenance in harsh mining environments. Additionally, air slide systems help minimize dust emissions, contributing to improved air quality in mining facilities.

Metallurgical Industry

In the metallurgical industry, especially in processes that involve the smelting and refining of metals, air slide systems are employed to convey fine materials such as metal powders, additives, and slag. These materials must be handled with care to prevent oxidation or contamination.

- Benefits: Air slide systems ensure a consistent flow of metal powders, helping to maintain the quality of the finished products. They also reduce equipment wear and tear, lowering the operational costs in metallurgical facilities.

Comparison Table of Air Slide System Applications

| Industry | Materials Conveyed | Benefits |

| Cement Industry | Raw meal, cement, clinker dust | Prevents particle segregation, reduces maintenance costs, consistent flow |

| Alumina and Bauxite | Alumina powder | Minimizes equipment breakdown, reduces energy consumption |

| Flour and Grain | Flour, grains | Dust-free transport, hygiene control, eliminates contamination risks |

| Chemical Industry | Calcium carbonate, soda ash | Prevents agglomeration, contamination-free transport |

| Pharmaceutical Industry | Drug powders | Preserves powder purity, precise flow control |

| Mining and Minerals | Lime, gypsum, phosphates | Low maintenance, reduces dust emissions, suitable for harsh environments |

| Metallurgical Industry | Metal powders, additives, slag | Consistent material flow reduces wear and tear on equipment |

Advantages of Air Slide Systems Across Industries

Across all the industries mentioned, air slide systems offer several overarching benefits:

- Energy Efficiency: Air slide systems require significantly less energy than mechanical conveyors because they rely on air and gravity to transport materials.

- Low Maintenance: Air slide systems last longer and require less maintenance because they have fewer moving parts, which reduces wear and tear.

- Dust-Free Operation: The enclosed nature of air slide systems minimizes the release of dust into the environment, which is critical in industries like pharmaceuticals and food processing where contamination must be avoided.

- Versatility: Air slide systems can handle a wide variety of materials, from very fine powders to larger granules, making them adaptable to different industrial needs.

- Gentle Handling: Since air slide systems do not use mechanical components that might damage delicate materials, they are ideal for industries that require gentle material handling, such as pharmaceuticals and food processing.

Conclusion

In many different sectors, air slide systems are a crucial part of material handling procedures. They are a favored option for situations where the transportation of fine powders and granules is crucial due to their capacity to transfer bulk materials effectively, dependably, and with little maintenance. Whether in cement production, chemical processing, or pharmaceutical manufacturing, air slide systems ensure that industries can maintain the quality of their products while optimizing their operational efficiency.

As industries continue to evolve, air slide systems will remain a critical technology for ensuring smooth and cost-effective material handling.