Filter presses are essential tools in many industries that require separation of liquids and solids. Whether in wastewater treatment, food processing, or chemical manufacturing, filter presses play a crucial role in enhancing efficiency and product quality. The key component of a filter press, the filter fabric, greatly influences the overall performance. In this guide, we’ll explore how to choose the right filter fabric for your filter press, considering factors like material types, fabric construction, and the specific needs of your filtration process.

Table of Contents

ToggleIntroduction to Filter Presses

The filter fabric is positioned between the plates to form the filtration chamber where the solids are trapped, and the liquid is allowed to pass through. The choice of filter fabric is critical because it impacts the filtration rate, cake quality, and longevity of the equipment.

Types of Filter Fabric Materials

Filter fabrics come in a variety of materials, each offering different advantages depending on the application. Strength, permeability, chemical resistance, and the fabric’s capacity to tolerate high temperatures are all influenced by its material. Below are some commonly used filter fabric materials:

a) Polyester (PET)

Polyester filter fabrics are the most common choice due to their cost-effectiveness, good mechanical strength, and resistance to abrasion. Applications requiring moderate to medium chemical resistance are especially well-suited for them.

Advantages:

- Affordable

- High mechanical strength

- Good chemical resistance to acids and alkalis

- Low moisture absorption

Disadvantages:

- Not appropriate for uses involving high temperatures

- Limited resistance to certain chemicals

b) Nylon (PA)

Nylon is often used for applications requiring higher chemical resistance and flexibility. It works effectively in filtration procedures involving strong chemicals or elevated temperatures.

Advantages:

- Stronger than polyester

- Higher chemical and temperature resistance

- Flexible and durable

Disadvantages:

Higher cost compared to polyester

Absorbs moisture, potentially impacting performance in processes.

c) Polypropylene (PP)

Polypropylene filter fabrics are well-known for their great heat resistance and exceptional resistance to a variety of chemicals. These fabrics are ideal for processes that involve acidic or alkaline solutions.

Advantages:

Superior resistance to chemicals and temperatures

Low moisture absorption

Durable in harsh environments

Disadvantages:

More expensive than polyester

Limited mechanical strength in comparison to other materials like nylon

d) PTFE (Teflon)

Polytetrafluoroethylene (PTFE) is often used for highly corrosive applications. Almost all chemicals, even powerful acids, alkalis, and solvents, cannot harm it. PTFE fabrics are durable and highly effective in demanding filtration processes.

Advantages:

- Extremely high chemical resistance

- High heat resistance

- Non-stick properties, making cleaning easier

Disadvantages:

- Very expensive

- Limited mechanical strength, which can make handling more difficult

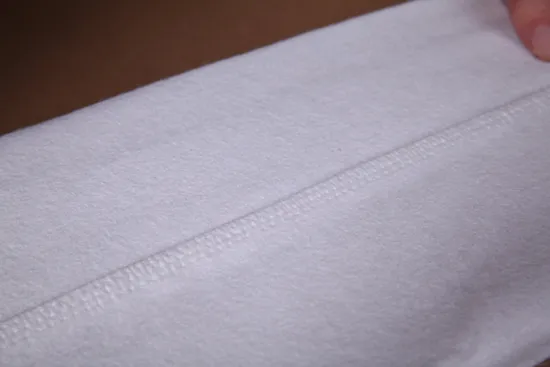

Fabric Construction: Woven vs Non-Woven

Another important factor influencing filtration performance is the filter fabric’s structure. The two primary types of fabric constructions are woven and non-woven.

a) Woven Fabrics

Two sets of strands are interlaced at right angles to one another to create woven fabrics. They provide outstanding resilience to mechanical stress, strength, and durability. These fabrics are ideal for applications requiring high pressure and long service life.

Advantages:

- Strong mechanical properties

- Suitable for high-pressure operations

- Long-lasting and durable

Disadvantages:

- Less flexible compared to non-woven fabrics

- Can have lower filtration efficiency due to larger pore sizes

b) Non-Woven Fabrics

Heat, pressure, or adhesives are used to fuse fibers together to create non-woven textiles. These textiles offer a larger surface area for filtration and are typically more flexible. They tend to have finer pores and higher filtration efficiency.

Advantages:

- Greater filtration efficiency

- More flexible, easier to handle

- Fine pores for better filtration

Disadvantages:

- Generally weaker than woven fabrics

- Shorter lifespan, especially in high-pressure or high-stress applications

Filtration Requirements and Fabric Selection

The particular needs of the filtration process must be taken into account when choosing a filter cloth. Key factors include:

a) Particle Size and Filtration Efficiency

The particle size of the solid materials being filtered directly affects the type of fabric required. For finer particles, fabrics with smaller pores (often non-woven fabrics) are needed to prevent clogging. Conversely, for larger particles, fabrics with larger pores can be used.

| Application | Particle Size | Recommended Fabric Type |

| Food Processing | Large (1-10 mm) | Woven Polyester |

| Chemical Filtration | Medium (10-50 microns) | Non-Woven Polypropylene |

| Pharmaceutical | Small (1-10 microns) | Non-Woven Nylon |

b) Chemical Compatibility

Different materials require fabrics with varying degrees of chemical resistance. For applications involving aggressive chemicals, such as in chemical manufacturing or wastewater treatment, it is crucial to select a fabric material that can withstand the chemicals involved without degrading or losing its strength.

| Chemical | Suitable Fabric Materials |

| Acids | Polyester, Polypropylene |

| Alkalines | Nylon, Polyester |

| Solvents | PTFE, Polypropylene |

c) Temperature Resistance

Temperature can significantly affect the performance of filter fabrics. Higher temperatures can degrade fabrics, especially those made from polyester or nylon. Polypropylene and PTFE are perfect for high-temperature settings.

| Temperature Range | Suitable Fabric Materials |

| Below 100°C | Polyester, Nylon |

| 100°C to 180°C | Polypropylene, Nylon |

| Above 180°C | PTFE, Polypropylene |

d)Flow Rate and Pressure

The filtration process may require fabrics that can handle high flow rates and pressures without deforming or losing their filtering efficiency. Woven fabrics tend to perform better under high pressure due to their robust construction, while non-woven fabrics offer superior filtration efficiency but may not be as durable in high-pressure situations.

Fabric Maintenance and Lifespan

Proper maintenance is essential to ensure the longevity of filter fabrics. Over time, fabrics may become clogged with particles or damaged by chemicals, temperature, or mechanical stress. The fabric’s lifespan and the effectiveness of the filtration process can both be maintained with routine washing and examination.

Cleaning Methods: Depending on the material, filter fabrics can be cleaned using water, chemical solutions, or ultrasonic cleaners. To avoid damage, it’s critical to adhere to the manufacturer’s instructions.

Replacement Timing: Over time, the fabric may lose its filtering ability due to wear or clogging. Regular checks should be performed to determine when replacement is necessary, as using worn-out fabric can negatively impact filtration efficiency.

Conclusion

Choosing the right filter fabric for your filter press is essential for maximizing filtration efficiency, extending equipment lifespan, and ensuring product quality. By considering factors like material type, fabric construction, and specific filtration needs, you can select the most appropriate fabric for your application.

Understanding the different kinds of fabrics and their properties is crucial to making the best choice. Whether you need high chemical resistance, superior filtration efficiency, or durability under pressure, there is a filter fabric that can meet your needs. Don’t forget to also consider maintenance requirements to ensure long-term performance.

By investing in the right filter fabric, you ensure that your filtration process runs smoothly, efficiently, and cost-effectively.