Filter Cartridge Design Dust Collectors

The cartridge dust collector with the advanced properties of small size, big air flow volume, high filter efficiency, small investment which are widely used many industrial occasions for dust collection.

Zonel Filtech can provide the oblique installed filter cartridge dust collectors, vertical installed filter cartridge dust collectors, portable dust collector, silo dust collectors, etc.

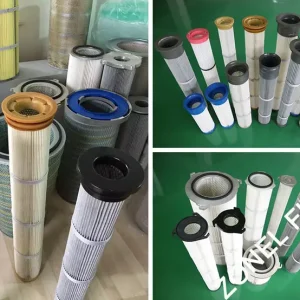

Besides the dust filter machines, Zonel Filtech also provide replacement filter cartridges for cartridge dust collector for both Zonel made and other OEMs, and special size and usage filter cartridge can be customized.

Welcome to cooperate with Zonel Filtech! (How to choose the suitable cartridge dust collector?)

Oblique Installing Cartridge Dust Collector

The general introduction of oblique installing filter cartridge dust collector:

The oblique installing cartridge filter with the dust air flow direction from up side to lower size, which can help to clean the filter cartridges so as to make the cartridge dust collector keep a lower resistance.

The oblique installing dust collector cartridge filter (dry dust collector) can help to purify the dust air for many industrial areas, include chemical processing, minerals, blasting, welding, plasma cutting, dry powder handling, and metal finishing (polishing, cutting, etc) just to name a few.

The cartridge dust collector with the pulse cleaning system (pulse cartridge dust collector) with the properties of lower cost, easy to installing and maintenance, and special better for some lower density dust air purifying.

The properties of the oblique installing industrial dust collector from Zonel Filtech:

1.With the modular structure design, easy delivery and installing.

2.All the machines will be tested completely before delivery.

3.The optimized structure makes the machine occupy very small space.

4.The filters can be customized according to different dust air content.

5.The filter efficiency more than 99.9%, with a longer service life.

6.The replacement filter cartridges can be changed at outside of the machine, with a safer working circumstance.

Applications:

Sand blasting workshop, polishing workshop, welding workshop, plasma / laser cutting workshop, pharmaceutical plants, food processing plants, chemical plants, mining, cement plants, plastic processing plants, ceramic workshop, carbon black processing plants, etc.

We can customize the filter bag housing according to the given material.

The typical parameters of Oblique Installing Cartridge Dust Collector:

Model Flow Vol. m3/hr filter area (㎡) Resis.Pa Air/Cloth R. m/min Purging Airm/min 0.55-0.65 MPa Efficiency % Lmm Wmm Hmm Weight Kg XCS-2-8 2500-4000 84 500-1000 0.5-0.8 0.25-0.3 99.9 1100 2140 3000 300 XCS-2-12 3800-6000 126 0.25-0.3 1473 2140 3000 1100 XCS-3-12 3800-6000 126 0.25-0.3 1016 2140 3450 862 XCS-2-16 5000-8000 168 0.25-0.3 2032 2140 3000 1480 XCS-4-16 5000-8000 168 0.25-0.3 1016 2140 3900 1045 XCS-2-24 7600-12000 252 0.3-0.4 2946 2140 3000 2220 XCS-3-24 7600-12000 252 0.3-0.4 2032 2140 3450 1724 XCS-4-32 10100-16200 336 0.3-0.4 2032 2140 3900 2090 XCS-2-36 11500-18000 378 0.3-0.4 4420 2140 3000 3330 XCS-3-36 11500-18000 378 0.3-0.4 3048 2140 3450 2564 XCS-3-48 15000-24200 504 0.3-0.4 4064 2140 3450 3448 XCS-4-48 15000-24200 504 0.5-0.6 3048 2140 3900 3135 XCS-3-60 18900-30000 630 0.5-0.6 5080 2140 3450 4310 XCS-4-64 20000-32000 672 0.5-0.6 4064 2140 3900 4180 XCS-3-72 22700-36300 756 0.5-0.6 6096 2140 3450 5172 XCS-4-80 25200-40300 840 0.5-0.6 5080 2140 3900 5225 XCS-4-96 30200-48400 1008 0.5-0.6 6096 2140 3900 6270 XCS-4-112 35300-56500 1176 0.5-0.6 7112 2140 3900 7315 XCS-4-128 40000-64500 1344 0.5-0.6 8128 2140 3900 8360

Vertical installing cartridge dust collector

General introduction of the vertical installing cartridge dust collector:

The vertical installing cartridge dust collector as usual designed for some industrial which the dust air with high dust content, at meanwhile with a high filter speed / Air cloth ratio, the special designed air way makes the filters with a perfect operation state. The vertical installed filter cartridges will help to solve the purging problems, also can avoid the dust drop from above filters so as to guarantee the filter houses always with a lower resistance and increase the service life.

The properties vertical installing cartridge dust collector:

1.Suitable for higher dust content circumstance, with a higher filter speed.

2.Can avoid the dust drop from the above filter when compare to the oblique installing cartridge filters.

3.Special designing of the air way helps to make the big particles drop to the hopper directly.

4.With a lower resistance help to prolong the service life of the filter cartridges.

5.With the optimal designed pulse jet purging system make the clean works easy and perfect.

6.Can design according to the customer requirements.

7.Fast delivery.

Applications:

Metal processing, mining, cement industries, ceramic industries, carbon black industries, pharmaceutical industries, chemical plants, metallurgy industries, hot air spray industries, rubber industries, battery industries, mixing plants, and other powder processing occasions, etc.

The typical parameters of the vertical installing cartridge dust collectors:

Model Cartridge qty (pcs) Filter Area (sq.m) Air volume (CMH) ZF/DZS-2-4 4 112 6500 ZF/DZS-2-8 8 224 13000 ZF/DZS-2-12 12 336 26000 ZF/DZS-2-16 16 448 26000 ZF/DZS-2-20 20 560 32500 ZF/DZS-3-6 6 168 9600 ZF/DZS-3-12 12 336 19200 ZF/DZS-3-18 18 504 28800 ZF/DZS-3-24 24 672 38400 ZF/DZS-3-30 30 840 48000 ZF/DZS-4-8 8 168 12000 ZF/DZS-4-16 16 224 24000 ZF/DZS-4-24 24 672 36000 ZF/DZS-4-32 32 896 48000 ZF/DZS-4-40 40 1120 60000

Silo Dust Collectors

The general introduction:

Cement silo top dust collector also called silo dust collector, cement silo dust collector, silo top silo venting filters, etc, which is for dust collection during the silo filling works.

The cement silo top dust collector was combined with filter tank, filter bag/filter cartridges, air bag, solenoid pulse jet valves, the hopper and fan are optional according to the operation conditions.

The properties of the silo dust collector from Zonel Filtech:

1.Modular design, fast installation.

2.Small size, big flow, economical solution for silo dust collection.

3.PLC control, pulse jet purging, easy operating and long service life.

4.Can design according to client’s requirements.

Portable Filter Cartridge Dust Collector

The general introduction:

The portable dust collector mainly equipped for the circumstance which dust cause positions not fix or temporary dust points for dust collection and fume removal.

The dust collector is modularized, installed the high efficiency dust filter cartridges inside, with self-purging system and dust suction pipe.

The filter cartridge dust collectors with a small size and with castors, can move easily according to the requirements.

The properties:

1.Easy to move, can collect the dust in different positions easily.

2.Suitable for some fine fume collection, such as welding fume; also suitable for some big particles collection.

3.Installed the high efficiency filter cartridge, filter efficiency more than 99%, the service life of the cartridge more than 1 year, easy maintenance.

4.With self-clean system, easy to purging the filter cartridges.

5.With the shelf and flexible dust suction pipe, the length can customize according to client’s requirements.

6.With air blower switch, purging switch, emergency switch, operating safe and stable.7.The dust filter cartridge install and uninstall easily; the pressure gauge installed at the panel, supervise the operation state timely.

Application:

Mainly play the role as Welding working shop dust collector, polishing plants dust collector, food industries dust collector, pharmaceutical plants dust collector, the packing position of the powders dust collector and other occasion need to purify the dust air.