Air Slide System

Air Slide System also called air slide chute or fluidizing conveying system or pneumatic conveyor system which widely used in cement industries (cement air slide conveyor), food processing industries (grain air slide conveyor, etc), energy industries and so on for the powdered or granular materials air slide conveying.

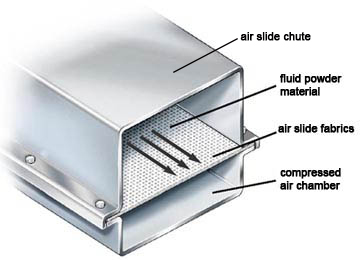

The system combined with the upper chute, air slide fabrics and lower chute. The pressed air filling from lower chute that pass through the air slide fabrics and fluidizing the dry powdered/granular materials on the upper chute then make them flowing/conveying to the lower position of the system due to the gravity so as to finish the transportation works.

The fluidizing particles with less abrasion to the system, and the whole system nearly don’t move when it working that make the system very durable and easy to maintenance; also the powders conveyed in the air tight chute, so they won’t loss when transporting and won’t cause the pollution problem as well.

General introduction of air slide system

Air slide systems also called air slide conveyor / air slide chute or pneumatic fluidizing conveying systems, which widely used in cement plants for raw materials and the cement conveying, also be used in the industries of bauxite, CaCO3, carbon black, gypsum, flour and other industries for powders or small particles (diameter < 4mm) conveying.

The air slide conveyor was combined by upper chute, air slide fabric, below chute, which fixed by bolts at the edges of the chute and sealed by silicon rubber or some high temperature resistance sealing material. The air slide chute was installed from higher position (inlet) to the lower position (outlet) with a special angle (mainly from 2~12 degree), with a well-sealed feeding set, when the pressed air enter into the below chute, the air will pass the air slide fabrics and mixed with powders at the upper chute to make the powder fluidized which will be conveyed from the higher side to the lower side position due to the gravity.

Relevant products:

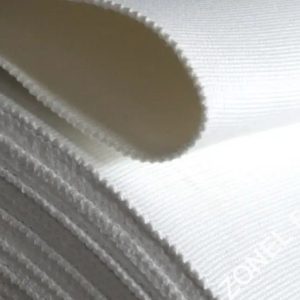

Polyester air slide fabric

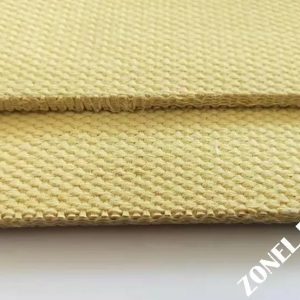

Aramid air slide fabric

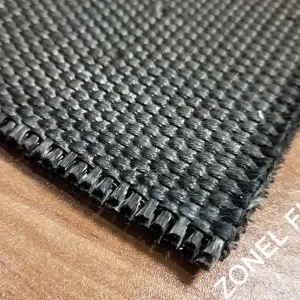

Basalt air slide fabric

Air slide hose

Typical parameters of the air slide chute system from Zonel Filtech.

Model No. | Air slide conveying volume (m³/h) | Air pressure KPa | Air consumption (m2- air slide fabric. min) | |||||

Cement 6% | Raw meal 6% | Cement 10% | Raw meal 10% | |||||

ZFW200 | 20 | 17 | 25 | 20 | 4~6 | 1.5~3 | ||

ZFW250 | 30 | 25.5 | 50 | 40 | ||||

ZFW315 | 60 | 51 | 85 | 70 | ||||

ZFW400 | 120 | 102 | 165 | 140 | ||||

ZFW500 | 200 | 170 | 280 | 240 | ||||

ZFW630 | 330 | 280 | 480 | 410 | ||||

ZFW800 | 550 | 470 | 810 | 700 | ||||

Properties of the air slide chute from Zonel Filtech

1.Simple system design with a lower investment.

2.Easy maintenance.

3.Won’t lost of the material or pollution when conveying the material.

4.The whole air slide chute (except the air blower) nearly no moving part, working quiet, lower power consumption (mainly 2~5 KW), no need to grease the accessories, safe.

5.Can change the convey direction and feeding position easily.

6.High temperature resistance (can stand 150 degree C or more), anti-corrosive, anti-abrasion, lower moisture absorption, lower weight, smooth surface, longer service life.

Main application:

Can transport nearly all of the dry powders (moisture mainly <2%) with the particle size less than 4mm, which widely used in the industries of cement, bauxite, CaCO3, carbon black, gypsum, flour, grain, and other industries such as chemical powders, machinery accessories or raw material particles and so on.

Zonel

ISO9001:2015