In the realm of bulk material handling, efficiency and precision are paramount. The air slide conveyor system has emerged as a groundbreaking innovation in bulk material handling. This article delves into the workings, benefits, and applications of air slide conveyors, showcasing why they are increasingly favored in industries such as cement, mining, and manufacturing.

Table of Contents

ToggleUnderstanding Air Slide Conveyors

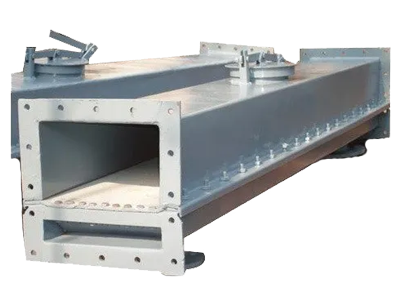

Air slide conveyors, also known as air gravity conveyors or fluidized conveying systems, utilize the properties of fluidization to transport fine-grained bulk materials, such as powders and granules, over a flat or slightly inclined plane. The system comprises a rectangular chamber separated by a porous fabric. When compressed air is introduced through the fabric, it suspends the bulk material above it, creating a fluid-like state. This air cushion drastically lowers friction, enabling the material to move smoothly along the conveyor’s length.

Design and Components

The design of an air slide conveyor is relatively simple yet highly effective. Key components include:

Upper and Lower Chambers: The upper part holds the material, while the lower section channels compressed air.

Porous Fabric: Often made from durable and air-permeable materials like polyester, this fabric supports the material while allowing air to pass through.

Air Supply System: Compressed air is essential for fluidization, and its flow must be precisely controlled to ensure efficient material transport.

Advantages of Air Slide Conveyors

Air slide conveyors offer several advantages that make them an attractive choice for many industries:

Energy Efficiency: They consume less power compared to other conveying systems since they utilize the natural force of gravity aided by air.

Low Maintenance: Since air slides have no moving parts, they need less maintenance, which minimizes downtime and cuts operational costs.

Dust-Free Operation: Air slides, lacking moving parts, demand minimal maintenance, thereby decreasing downtime and lowering operational costs.

Gentle on Materials: The gentle handling process minimizes wear and degradation of the material, preserving quality.

Versatility: Air slides can handle a wide range of bulk materials and can be designed to fit into various plant layouts due to their compact and flexible configuration.

Applications in Various Industries

Air slide conveyors are versatile and can be used in various sectors:

Cement Industry: They are ideal for transporting cement from the mill to the storage silos, ensuring a continuous and dust-free flow.

Mining and Minerals: Efficient in handling fine ores and minerals, air slides help in processing and transporting powders like gypsum, limestone, and coal dust.

Chemical Processing: The chemical industry benefits from the gentle handling and non-contaminative features of air slides, especially when dealing with reactive or hazardous powders.

Food Processing: In facilities dealing with flour, sugar, and other granular products, air slides ensure hygienic and efficient transport.

Installation and Operational Considerations

While air slide conveyors are advantageous, certain factors need consideration to optimize their performance:

Proper Installation: Incorrect installation can lead to uneven air distribution, which might impede material flow. Professional installation and regular inspection are crucial.

Air Pressure and Volume: Balancing the airflow is critical. Too much air can cause excessive wear or blow the material out, while too little can hinder movement.

Material Characteristics: The system’s efficiency can vary depending on the particle size, moisture content, and other properties of the bulk material.

Future Prospects

The future of air slide conveyors looks promising as technological advancements continue to enhance their efficiency and adaptability. Innovations in materials used for the porous fabric and improvements in airflow control systems are expected to further refine these conveyors. Additionally, integrating smart sensors and IoT technology could lead to smarter, more autonomous systems that can adjust operational parameters in real time, maximizing efficiency and reducing human intervention.

Conclusion

Air slide conveyors mark a substantial advancement in bulk material handling technology. Their ability to transport materials efficiently, safely, and economically makes them an essential component in modern industrial operations. As industries continue to seek more sustainable and cost-effective solutions, air slide conveyors are likely to play an increasingly important role in the global market. Their simplicity, coupled with robust performance, ensures that they remain a preferred choice for handling bulk materials across diverse sectors.