Home » Air Slide

Air Slide

Categories

Air slide hose according to their usage also called bulk cement aeration hose, silo hose, cement air slide hose, cement trailer air slide hose, aeration hose, etc.

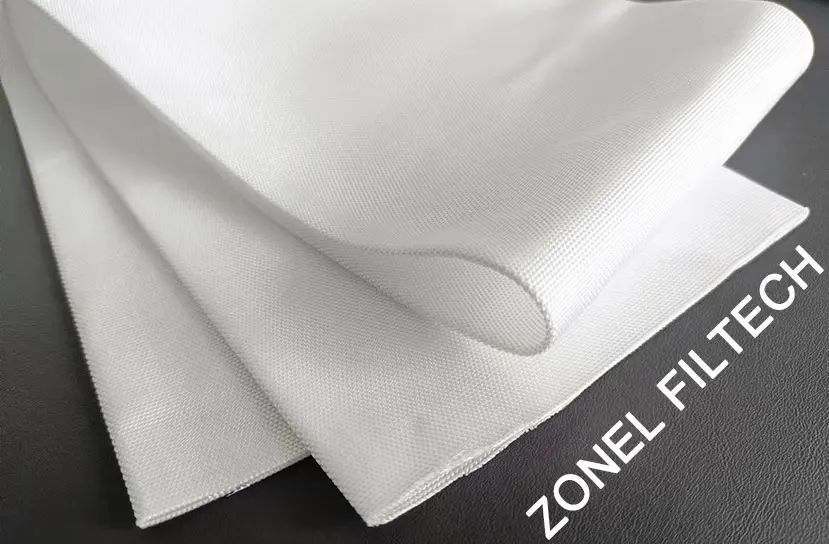

The Zonel Filtech was one of the most professional air slide hose manufacturers of China can offer the high strength pneumatic air slide hoses with different sizes and special requirements for air slide convey systems, which made of polyester industrial spun yarn in warp side and polyester industrial filament at the weft side.

One side of the customized air slide hose with PU/acrylic acide coating, and the other side without. The coating can improve the abrasion resistance of the air slide hose, at the meantime can optimize the air dispreading in the other side without coating so as to fluidize the material easier and make the material with a suitable flow direction and increase the conveying efficiency.

Air Slide System also called air slide chute or fluidizing conveying system or pneumatic conveyor system which widely used in cement industries (cement air slide conveyor), food processing industries (grain air slide conveyor, etc), energy industries and so on for the powdered or granular materials air slide conveying.

The system combined with the upper chute, air slide fabrics and lower chute. The pressed air filling from lower chute that pass through the air slide fabrics and fluidizing the dry powdered/granular materials on the upper chute then make them flowing/conveying to the lower position of the system due to the gravity so as to finish the transportation works.

The fluidizing particles with less abrasion to the system, and the whole system nearly don’t move when it working that make the system very durable and easy to maintenance; also the powders conveyed in the air tight chute, so they won’t loss when transporting and won’t cause the pollution problem as well.

Air slide systems / pneumatic conveyor system combined with the upper chute, air slide fabrics and lower chute. The pressed air from lower chute pass through the air slide fabrics to fluidize the powdered/granular on the upper chute then make them flowing/conveying to the lower position of the system due to the gravity.

The fluidizing particles with less abrasion to the system, and the whole system nearly don’t move when it working that make the system very durable and easy to maintenance; also the powders be conveyed in the air tight chute, so they won’t loss when conveying and won’t cause the pollution problem.

Zonel Filtech provide both air slide chute system and replacement air slide fabrics. According to the different materials, the air slide fabrics from us can be divided into the polyester air slide fabric, basalt air slide canvas, Aramid air slide belt / Nomex air slide membrane/ Kavlar air slide cloth. Besides the air slide fabrics, we also provide the super quality air slide hoses.

Zonel Filtech provide good quality Aramid air slide fabric, both Para-aramid air slide fabric (aramid 1414 air slide belt or Kevlar air slide canvas) and Meta-aramid air slide fabric (aramid 1313 air slide membrane or Nomex air slide canvas) are available for various working circumstances and applications. The Para-aramid air slide belt with the properties of fire proof, high tensile strength and abrasion resistance, longer service life, the maximum operation temperature is 250degree C, instant peaks is 350 degree C. For the Meta-aramid air slide cloth, which is fire proof and high temperature resistance air slide fabric as well, the continuous operation temperature is 220 degree C, maximum peaks can up to 250 degree C. Aramid fiber also can be needle punched into nonwoven aramid air slide belt (Nomex nonwoven air slide fabric or Kevlar nonwoven air slide belt) so as to offer some high temperature resistance but economical solutions for the air slide systems and homogenization systems.

ZONEL brand high tensile strength air slide fabric is a belt canvas mainly used for pneumatic transmission of cement, bauxite, carbon black, gypsum, grain, flour and so on, as well as equipped to fluid bed and powder mixing tank / homogenization silo, which with a special and controllable air permeability can help to improve the conveying efficiency, in the mean while reduce pollution, and also guarantee the uniformity of the mixed powders.

Zonel Filtech provide good quality basalt filament air slide fabrics / basalt fluidization fabric for air slide systems and homogenization usage in high temperature occasion, the maximum temperature can be up to 700-degree C.

The Basalt Air Slide Fabric with the properties of smooth surface and equal air permeability, strong construction, excellent for heat resistance, with the long service life with a perfect performance.

Zonel Filtech provide super quality polyester air slide fabrics for air slide systems / pneumatic conveyor systems and the homogenization silo, etc.

The polyester air slide belt from Zonel Filtech can be divided into polyester spun yarn air slide canvas, polyester filament air slide membrane and polyester nonwoven air slide cloth for different usages and requirements from the clients.

The filament polyester air slide fabric with a smooth surface and equal air permeability, strong construction, excellent for abrasion resistance, durable; the spun yarn polyester air slide belt with the same construction as the filament air side membrane, also offered widely for air slide solutions and mixing the powdered/granular in homogenization silo, with the competitive price; the nonwoven air slide belt, with the needle punched nonwoven construction (nonwoven polyester air slide cloth), easy installing, the width can be customized within 3.5 meters.