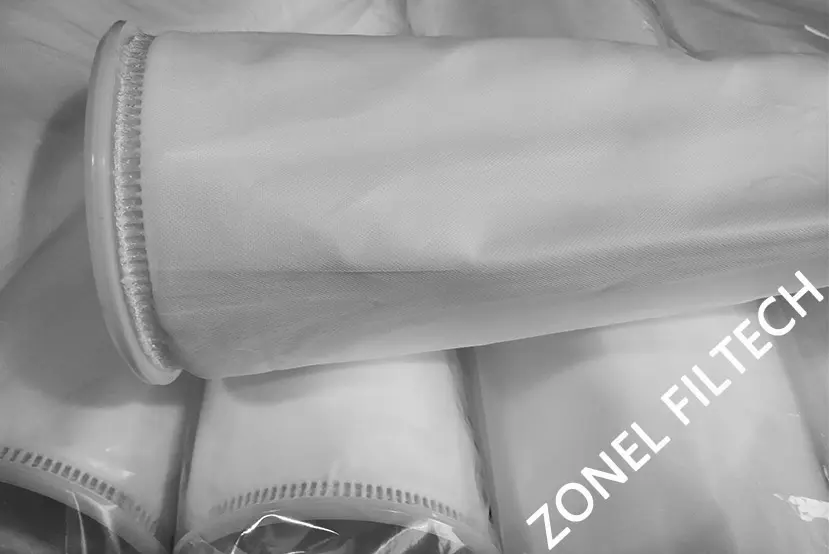

Absolute Rated Filter Bag / Absolute Efficiency Filter Bag

For the traditionally designed nonwoven liquid filter bags, as usual, the filter efficiency is around 60~70%, which just can be used for some primary filtration, but for some high-efficiency request occasions is not applicable.

To break this limitation and offer higher efficiency but economical solutions, Zonel Filtech developed the PPA high-efficiency liquid filter bags which is pushing the boundaries of bag filtration technology far beyond traditional designs. The filter bag with a filter efficiency more than 99%, in some measure, we call it an absolute rated filter bag.

The Zonel brand PPA absolute filter bags adopted the micro PP fiber material with multi-layers made of different density/workmanship filter materials and then put them according to the certain order so as to make the filter bags with different micron sizes and can get the higher filter efficiency as requested to accompany with end users liquid filter housings for various applications.

General introduction for PPA absolute rated filter bag

For the traditionally designed nonwoven liquid filter bags, as usual, the filter efficiency is around 60~70%, which just can be used for some primary filtration, but for some high-efficiency request occasions is not applicable.

To break this limitation and offer higher efficiency but economical solutions, Zonel Filtech developed the PPA high-efficiency liquid filter bags which are pushing the boundaries of bag filtration technology far beyond traditional designs. The filter bag with a filter efficiency of more than 99%, in some measure, we call it an absolute rated filter bag.

The Zonel brand PPA absolute filter bags adopted the micro PP fiber material with multi-layers made of different density/workmanship filter materials and then put them according to the certain order so as to make the filter bags with different micron sizes with the high filter efficiency as requested and can be adapted to different applications.

The micron size from 1.5~25 can be customized, any help needed, welcome to contact Zonel Filtech!

Relevant products:

Micron-rated filter cloth and filter bags

Filter mesh/bolting cloth

S.S. bag filter housing

Technical specification of PPA micron absolute rated filter bag

1. Size and operation details for PPA micron absolute rated filter bag:

Item | Size (mm) (dia. X L) | Filter area (㎡) | Max. Operating Temperature ("C) | Max. Operating Pressure (bar) | Suggest pressure To change bag (bar) | Max. Flow rate (m³/h) |

Size 1 # | ∅180*435 | 0.24 | 90 | 2.5 | 0.8~1.5 | 8 |

Size 2 # | ∅180*810 | 0.48 | 90 | 2.5 | 0.8~1.5 | 15 |

2. Filter efficiency data for PPA micron absolute rated filter bag:

Material | Model | Particles size at common removal efficiencies (micron) | △P (PSI) size 2# @10m3/hr | Max. operating Temperature (°C) | ||||

PP | >60% | >90% | >95 | >99% | >99.9 | |||

PPA 1.5 | 0.2 | 0.6 | 0.8 | 1.5 | 5 | 0.09 | 90 | |

PPA 3 | 0.8 | 1 | 2 | 3 | 5 | 0.22 | 90 | |

PPA 5 | 1 | 2 | 3 | 5 | 15 | 0.05 | 90 | |

PPA 10 | 2 | 4 | 5 | 10 | 25 | 0.04 | 90 | |

PPA 25 | 10 | 25 | 30 | 25 | 35 | 0.03 | 90 | |

The properties of PPA absolute rated high-efficiency liquid filter bag

1. Multi-layer design with higher filtration efficiency.

2. The different layers with different open sizes be laid in order, so the filter bags won’t be blocked at any layer quickly, so with a much longer life when compared to the traditional design filter bags.

3. A 100% welded seam makes the filter bag without leakage from the sewing seam as before.

4. With different top rings for choice, suitable for various bag filter housing.

5. The filter bags have no additives, such as resins, binders, or surface treatments, and food grade material adopted.

The applications of PPA absolute rated high-efficiency liquid filter bag

1. Food and beverage filtration: such as beer, wine, juice, and vinegar processing.

2. Oil filtration: such as hydraulic oils, lubricating oils filtration, etc.

3. Fine chemicals filtration: decolorant, lacquers, developers, pharmaceutical chemicals processing, etc.

4. Other fine particle filtration, such as activated carbon removal in process systems, fine particle removal in parts cleaning, printing ink filtration, etc.