In the field of industrial filtration, the effectiveness and dependability of filter housings are crucial. Stainless Steel (SS) filter housings are especially favored for their robustness and longevity.

This article delves into the comparative merits of SS Single and Multi Cartridge Filter Housings, offering detailed insights into their construction, applications, and personality comparison to better understand their fit in various industrial contexts.

Table of Contents

ToggleTwo Types of Filter Housings Comparison

Feature | SS Single Cartridge Filter Housing | SS Multi Cartridge Filter Housing |

Capacity | Low to moderate flow rates | High flow rates, large volume |

Size & Space | Small, space-efficient | Larger, requires more space |

Maintenance | Easier, less frequent | More complex, but less frequent changes |

Cost Effectiveness | More economical for small scale | Cost-efficient for large scale |

Best Use Scenarios | Small industries, targeted applications | Large industries, continuous operation |

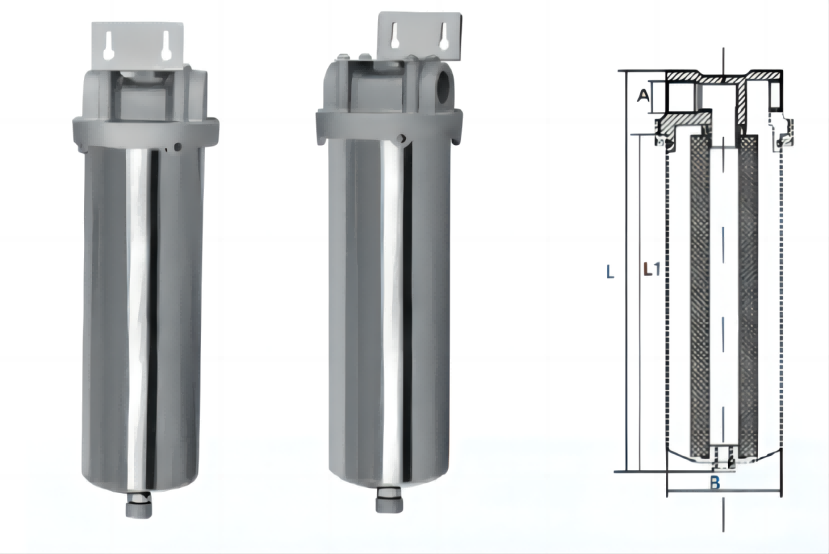

SS Single Cartridge Filter Housing

Construction: Constructed from premium stainless steel, offers superior corrosion resistance and withstands mechanical stress well.

Capacity: Designed to accommodate a single cartridge, this housing is perfect for systems requiring low to moderate flow rates. It provides precise filtration, making it suitable for sensitive applications.

Maintenance: Its straightforward design allows for easy access and quick cartridge replacement, minimizing downtime and maintenance costs.

Applications: Often used in laboratories, pilot plants, or in processes within the pharmaceutical and food industries where high purity is required on a smaller scale.

Cost: The initial investment is relatively low, making it an economical choice for smaller operations or those requiring targeted filtration.

SS Multi Cartridge Filter Housing

Construction: This housing is also made from high-grade stainless steel, designed to endure higher pressures and more severe conditions. It’s larger and more robust, suitable for handling substantial volumes.

Capacity: Capable of housing multiple cartridges, it is adept at managing high flow rates and large volumes, ideal for extensive industrial applications.

Maintenance: Though the maintenance is more labor-intensive due to the number of cartridges, the design facilitates easy access to all cartridges for cleaning and replacement.

Applications: Best suited for large-scale operations such as municipal water treatment, large food and beverage production facilities, and chemical processing plants where continuous, high-volume filtration is necessary.

Cost: Higher upfront costs are offset by efficiencies in handling larger volumes and reduced frequency of maintenance.

Operational Efficiency and Cost-Benefit Analysis

Both types of housing contribute to operational efficiency in different ways. The SS Single Cartridge Filter Housing is tailored for operations where space is a premium and the filtration needs are specific and focused. It’s cost-effective for small businesses or applications where budget constraints are significant.

On the other hand, the SS Multi Cartridge Filter Housing, with its capacity to handle higher volumes and pressures, suits industries looking to maximize productivity without compromising on the quality of filtration. Its design is particularly beneficial for continuous, large-scale operations, providing a reliable solution that requires infrequent maintenance despite its higher initial cost.

Conclusion

Choosing between SS Single and Multi Cartridge Filter Housing depends significantly on the specific requirements of the operation, including the scale of filtration, volume requirements, and operational budgets. Both offer distinct advantages that can cater to a wide range of industrial needs, ensuring that processes run smoothly and efficiently while maintaining high standards of purity and compliance.

This comparison not only illustrates the capabilities and applications of each type but also underscores the importance of selecting the right filter housing to optimize filtration performance and operational efficiency in various industrial settings.