Fiber Glass Needle Felt Filter Cloth/ Filter Glass Filter Bag

Due to the high-temperature resistant chemical fiber filter bags always the extremely high prices which is a heavy burden to the DC operators without doubts for every change. Getting a kind of high-temperature resistant filter bag but with lower cost become to the reality requirement from the filtration market, and fiber glass is the first choice.

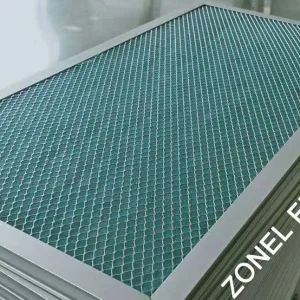

The Fiber glass needle felt filter cloth from Zonel Filtech adopted 100% glass fiber, with a sound needle punching and finish treatment, the fiber glass filter bags can be used in some extremely high-temperature occasions for dust collection.

To conquer the disadvantages of weak cohesive, poor folding resistance of the glass fiber felt, ZONEL developed fiber glass blended needle felt(similar to FMS needle felt or FMS filter bag), these fiber glass nonwoven filter materials already with the long time testing, nowadays are widely used for many applications, such as cement, metallurgy, mining, chemical, thermal power plants, etc.

General introduction of the fiber glass needle felt filter cloth and blended filter material

Due to the high-temperature resistant chemical fiber filter bags always with extremely high prices, such as Nomex filter bag, PPS filter bag, P84 filter bag, PTFE filter bag and so on which are the heavy burden to the DC operators without doubts for every change. To get a kind of high-temperature resistant filter bag but with lower cost become to the reality requirements from the filtration market, and fiber glass is the first choice.

The Fiber glass needle felt filter cloth from Zonel Filtech adopted 100% glass fiber plus the E-fiber glass scrim, after a sound needle punching works and with some reasonable finish treatment, then can be sewn into the fiber glass filter bag which can be used in some extremely high temperature occasions for dust collection.

For conquering the disadvantages of weak cohesive, poor folding resistance of the glass fiber felt, ZONEL FITLECH developed some new style fiber glass blended needle felt filter cloths (similar to FMS needle felt or FMS filter bag, we called fiber glass blending needle felt filter cloth), these fiber glass nonwoven filter materials after the long time testing which are widely used for many applications, such as cement, metallurgy, mining, chemical, thermal power plants, etc.

Relevant Products:

Fiber glass filter fabric

Fiber glass filter bag

Dust filter bags

Relevant specification of the glass fiber felt filter cloth and blended filter material:

Material: glass fiber + high-temperature resistance fiber such as Aramid (Nomex), PPS, P84, PTFE, etc + glass filament

Weight: > 880 g/sq.m

Tensile strength: Warp :> 1800 N/5cm; Weft :> 1800 N/5cm

Service Temperature: Continues: <260℃; Peaks: 280℃

Surface treatment for choice: glazed, heat set, PTFE suspension bath, PTFE membrane.

The properties of the fiber glass needle felt filter cloth and blended filter material

1. High Temperature Resistance: 260-280 degrees C

2. Excellent corrosion resistance (except HF)

3. Customized according to different operation conditions, longer service life.

4. Air permeability is higher and more stable can be operated with a higher air/ cloth ratio (up to 1.0~1.2m/min) when compared to the woven fiber glass filter fabric.

5. Abrasion resistance.

6. with an economical investment.

7. Can be used in a variety of complex and harsh environmental conditions.

Main applications of the fiber glass needle felt filter cloth and blended filter material:

Fiber glass needle felt filter cloth and blended type filter cloth are widely used for dust/ fume removal at the plants such as steel plants, nonferrous smelting works, chemical plants, carbon black production, Asphalt and cement plants, power plants, etc.

Zonel

ISO9001:2015