Spunbonded Nonwoven Filter Cloth For Pleated Style Filter Cartridges Production

Zonel Filtech provides good quality polyester spun bonded nonwoven fabrics for industrial filtration applications. (filter cartridge media)

The polyester spun bonded filter cloth with the specially designed pattern, combined with the 3D spun-bonded lapping workmanship, make the spun bonded filter cloth from Zonel Filtech with the properties of good air permeability; high filter efficiency; high stiffness, and not easy-to-change shape once pleated; big particles load and durable for various industrial applications. The spun bonded polyester nonwovens from Zonel Filtech can be finished with PTFE membrane laminated, water & oil repellent, and laminated with aluminum foil for anti-static and so on to meet the different requirements from different operating conditions.

Besides the spun-bonded filter cloth, Zonel Filtech also provides the sound quality membrane support layer for pleated-type filter cartridges.

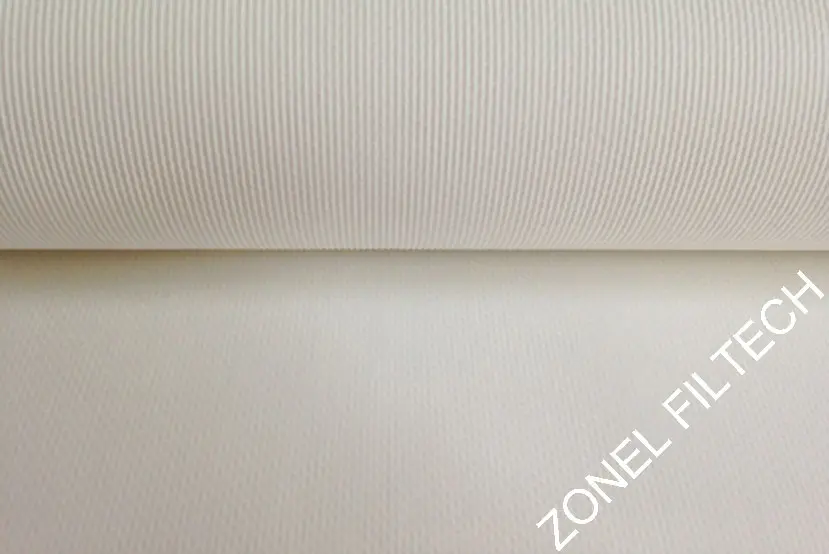

Spun Bonded Filter Cloth

Zonel Filtech developed the Bicomponent polyester (BICO polyester) serial spunbonded filter materials, which with the special designed pattern combined with the 3D spunbonded lapping workmanship to make the spun bonded filter cloth from Zonel Filtech with following properties when compare with the traditional spunbonded filter medias:

1. Good air permeability but with super filter efficiency.

After testing, the result shown that the BICO polyester serial spunbonded filter cloth with the similar weight always can get a better filter efficiency, but the air permeability is more than 90% higher than the traditional spunbonded polyester nonwovens, that’s mean the BICO polyester serial filter cartridge media can handle the much higher air volume but with a much lower resistance in cartridge filter housing under the same filter area basis, that can help to offer a most economical but better filter solution for our end users.

2. High tensile strength.

After testing, the result showed that for the similar weight spun-bonded filter cloth, the tensile strength of BICO polyester serial spun-bonded filter material is more than 90% higher than the traditional spun-bonded filter cloth, which means the A serial filter cartridge media can stand the higher pulse jet purging pressure and not easy to be broken, can get a longer service life.

3. Super stiffness

As usual, to increase the filter area of the filter cartridge, we will pleat the spun-bonded filter cloth with certain pleats on the pleating machine, the super stiffness of the spun-bonded filter media sure can help to make the filter cartridge always keep a correct shape and get a stable working performance.

4. Higher dust loading

The PET/PET Bicomponent spun-bonded filter cloth with 3D construction, has much better on dust loading capacity, can adopt a longer purging time, also not easy to cause secondary dust release, and increases the service life of the filter cartridges.

The spun-bonded filter cloth from Zonel Filtech can design with many finish treatments, such as to be treated with PTFE coating/ PTFE membrane laminated (spun-bonded with PTFE membrane), water & oil proof(spun-bonded water repellent media), and antistatic by aluminum foil (spun-bonded anti-static filter cloth) and so on, the filter fineness from 0.1 micron to 10 micron, filter efficiency more than 99%.

1. Normal polyester spun-bonded filter cloth.

Item | Weight (g/㎡) | Thick. (mm) | Air permeability (L/㎡.S@200Pa) | Tensile strength | Working temperature (°C) | Filter fineness (micron) | Efficiency (%) | |

Warp (N/5cm) | Weft (N/5cm) | |||||||

SB170A | 170 | 0.50 | >290 | >580 | >430 | ≤120 | 10 | >99.0 |

SB200A | 200 | 0.60 | >480 | >680 | >480 | ≤120 | 10 | >99.0 |

SB260A | 260 | 0.62 | >200 | >950 | >800 | ≤120 | 5 | >99.0 |

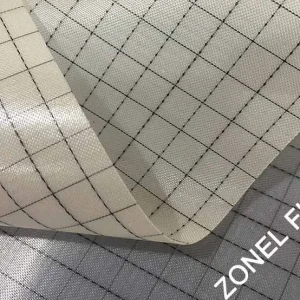

2. AL-Membrane Antistatic Spunbonded Polyester Filter Cloth.

Item | Weight (g/㎡) | Thick. (mm) | Air permeability (L/㎡.S@200Pa) | Tensile strength | Working temperature (°C) | Filter fineness (micron) | Efficiency (%) | |

Warp (N/5cm) | Weft (N/5cm) | |||||||

SB170AAS | 170 | 0.50 | >290 | >580 | >430 | ≤120 | 10 | >99.0 |

SB200AAS | 200 | 0.60 | >480 | >680 | >480 | ≤120 | 10 | >99.0 |

SB260AAS | 260 | 0.62 | >200 | >950 | >800 | ≤120 | 5 | >99.0 |

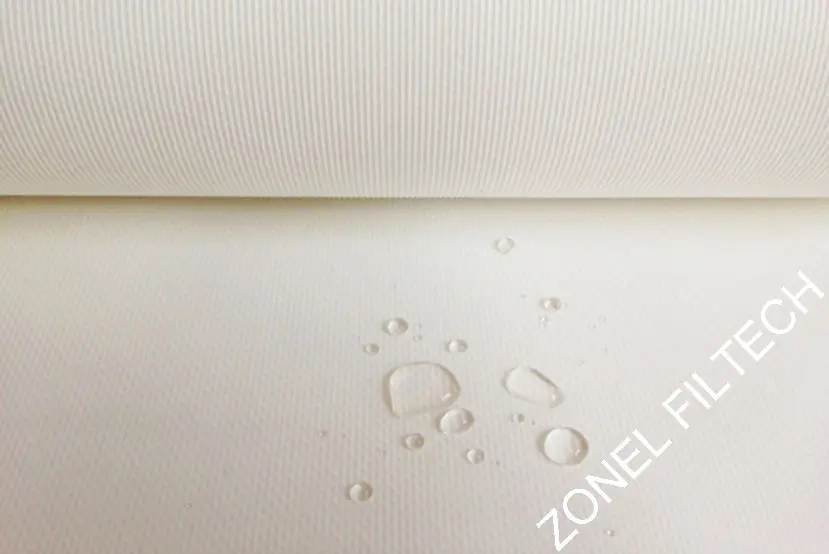

3. Water & Oil Repellent Treatment Spunbonded Polyester Filter Cloth.

Item | Weight (g/㎡) | Thick. (mm) | Air permeability (L/㎡.S@200Pa) | Tensile strength | Working temperature (°C) | Filter fineness (micron) | Efficiency (%) | |

Warp (N/5cm) | Weft (N/5cm) | |||||||

SB170AWR | 170 | 0.50 | >290 | >580 | >430 | ≤120 | 10 | >99.0 |

SB200AWR | 200 | 0.60 | >480 | >680 | >480 | ≤120 | 10 | >99.0 |

SB260AWR | 260 | 0.62 | >200 | >950 | >800 | ≤120 | 5 | >99.0 |

4.PolyesterSpunbonded Filter Cloth with PTFE membrane.

Item | Weight (g/㎡) | Thick. (mm) | Air permeability (L/㎡.S@200Pa) | Tensile strength | Working temperature (°C) | Filter fineness (micron) | Efficiency (%) | |

Warp (N/5cm) | Weft (N/5cm) | |||||||

SB170AM | 170 | 0.50 | >70 | >580 | >430 | ≤120 | 0.3 | >99.5 |

SB200AM | 200 | 0.60 | >70 | >680 | >480 | ≤120 | 0.3 | >99.5 |

SB260AM | 260 | 0.62 | >70 | >950 | >800 | ≤120 | 0.3 | >99.5 |

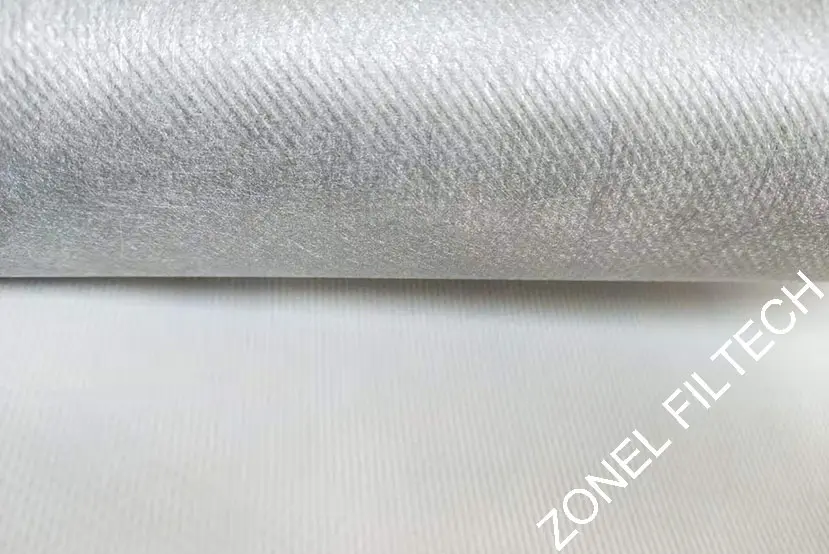

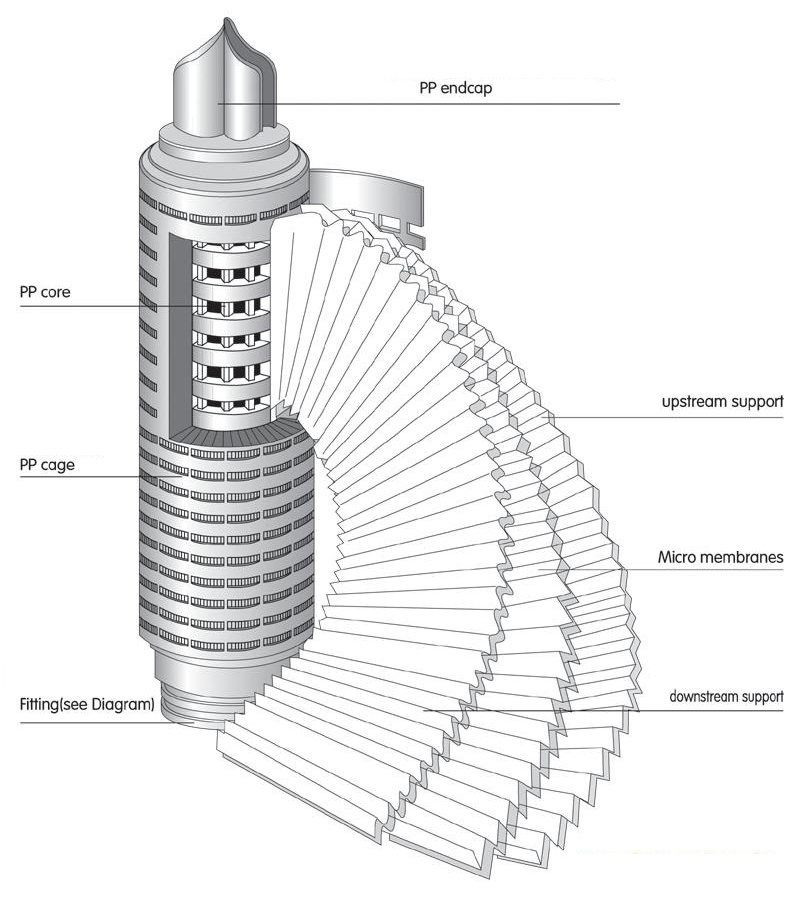

PET filament supports nonwoven

The structure of the micropore membrane pleated filter cartridge:

Zonel Filtech developed the polyester blended spun-bonded nonwoven for micropore membrane pleated filter cartridge production.

The material of the membrane support layer: PET+PA (bi-components spun-bonded nonwoven)

Color of the membrane support material: White.

Weight of the nonwoven support material: 30~120g/m2.

The width of the PET filament support is nonwoven: the standard width is 1.5 meters, and special widths can be customized.

The properties of the nonwoven fabric support from Zonel Filtech:

High tensile strength, stable size, ideal reinforcement material;

Good stiffness, suitable for pleating works, and ideal support material for filter membrane;

Good air/ water permeability, and lower resistance, make the filter cartridge not easy to block, and durable.