Filter Press Belt/ Vacuum Filter Belt/ Forming Belt

Zonel Filtech provides replacement filter belts for various filter machines, such as horizontal vacuum belt filters (offer vacuum filter belts), belt filter press (offer press filter belt), HVPF belt filters (tower belt filter), drum filters, paper or nonwoven forming machine, etc.

The filter belt can be produced with woven filter fabric belt and nonwoven needle felt filter belt, mainly applied for paper or nonwoven forming (forming mesh belt), juice squeezing (juice squeezing belt), as well as the general sludge dewatering for municipal sewage treatment, coaling washing slurry dewatering, red mud dehydration from the alumina industry, potash fertilizer production, phosphoric acid production, desulphurization gypsum dewatering, etc.

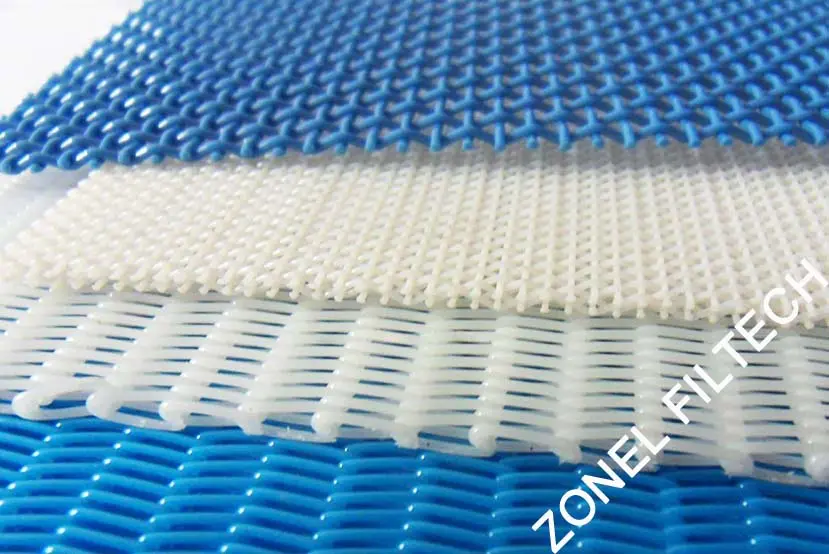

The woven filter belt (filter cloth belt, filter mesh belt) from Zonel Filtech adopted the optimized PET/ PP/ PA monofilament, multifilament, as well as the spun yarn then combined with various weaving patterns and sound finish treatments so as to meet the various filtration requirements for different applications and make them always keep the stable and good filtration performance.

Filter press belt/ vacuum filter belt/ Forming belt

Zonel Filtech provides replacement filter belts for various filter machines, such as horizontal vacuum belt filters (offer vacuum filter belts), belt filter press (offer press filter belt), HVPF belt filters (tower belt filter), drum filters, paper or nonwoven forming machine, etc.

The filter belt can be produced with a woven filter fabric belt and nonwoven needle felt filter belt, mainly applied for paper or nonwoven forming (forming mesh belt), juice squeezing (juice squeezing belt), as well as the general sludge dewatering, such as the municipal sewage treatment, coaling washing slurry dewatering, ceramic sludge treatment, red mud dehydration from the alumina industry, potash fertilizer production, phosphoric acid production, desulphurization gypsum dewatering, etc.

The woven filter belt (filter cloth belt, filter mesh belt) from Zonel Filtech adopted the optimized PET/ PP/ PA monofilament, multifilament, as well as the spun yarn then combined with various weaving patterns and sound finish treatment (heat setting and calendaring) so as to meet the various filtration requirements for different applications and make them always keep the stable and good filtration performance.

The nonwoven filter belt from Zonel Filtech adopted the industrial reinforced scrim and multi-sized fiber composited after needle punching and heat setting, glazing treatment with the properties of stable size, high filtrate output, and good filter efficiency.

Properties of the filter press belt/ vacuum filter belt/ Forming belt

1. The filter belt with high tensile strength design, and low tensile elongation, and the elongation is quality, the filter belt running stable;

2. The surface is well treated and very easy for cake release;

3. The filter belt surface especially the filter mesh belt surface with a thick the high strong design, which is not easy to fold, and can stand high pressure but with very good dimensional stability, good wear resistance, and durability;

4. The joints can be customized with clipper seams with various materials, also can be endless seam design, self-pin lock design, etc;

5. Offer full range of filter belts for various industrial applications, such as filter fabric belts, monofilament double layer weave (DLW filter belt) filter belts with PP and PET materials (PP DLW filter belt, polyester mesh filter belt, etc.) for suitable to be used in acid to alkali environment, also can be produced to monofilament blended with multifilament or spun yarn filter mesh belt, etc. Besides the above, Zonel Filtech also provides very good quality spiral mesh dewatering belts, nonwoven filter belts, etc;

6. The filter efficiency can be customized for different particles collection with very good filter efficiency, and offer the most economical solutions only.

The applications for the filter press belt/ vacuum filter belt/ Forming belt

1. Desulfurization gypsum dewatering in power plants (desulphurization mesh belt), chemical plants, steel plants, etc;

2. Food industry for juice squeezing (juice squeezing mesh belt), palm oil squeezing, vegetable processing industries;

3. Used as the forming belt (paper forming belt and nonwoven forming belt) for all kinds of forming conveying systems;

4. General slurry dehydration processing (dewatering filter belt/dehydration filter belt), such as municipal sewage treatment (general wastewater filter belt), coal washing slurry dewatering, ceramic sludge treatment, red mud dehydration from the alumina industry, paper making wastewater treatment and paper pulp washing (paper pulp washing belt), tailing concentrating (tailing filter belt), printing and dying sewage dehydration, electroplating wastewater treatment, potash fertilizer production, phosphoric acid production (phosphoric acid filter belt), desulphurization gypsum dewatering, etc.

The technical specification for typical items

MODEL | WEIGHT (g/㎡) | THICKN. (mm) | AIR PERMEA. (L/m2.S@200PA) | TENS. STREN. (N/cm) | BREAK ELONGAT. (%) | APPLICATION |

EYZ1128 | 1150 | 1.65 | 3000~ 3300 | >2200 | 19.0 | For slurry dewatering from the municipal waste water, ceramic waste water, coaling washing processing, etc. |

EYZ1423 | 1450 | 2.0 | 2260~ 2400 | >3600 | 28.0 | |

EYZ1334 | 1310 | 1.80 | 3200~ 3500 | >3500 | 17.0 | For slurry dewatering from paper making industry, alumina factory (red mud dewatering), tailing concentrating, etc. |

EYZ1327 | 1360 | 1.99 | 2500~ 2800 | >2600 | 40.0 | |

EZK1405 | 1429 | 1.76 | 240~ 600 | >3500 | 17.0 | Desulphurization processing (gypsum dewatering) at steel plant, thermal power plant, chemical plant, etc. |

EZK1102 | 1115 | 1.32 | 145~ 175 | >1350 | 34.0 | |

EZK0911 | 890 | 1.40 | 900~ 1300 | >2200 | 28.0 | For phosphoric acid plant, such as phosphor-gypsum dehydration, etc. |

PZK0604 | 600 | 1.07 | 380~ 430 | >1100 | 35.1 | |

EZK0914 | 995 | 1.43 | 1390~ 1500 | >2000 | 11.0 | For filtering and flotation in potash fertilizer production. |

EZK0920 | 939 | 1.30 | 1900~ 2100 | >1685 | 40.0 | |

ECX0950 | 890 | 1.88 | 5000 | >2000 | 28.0 | For nonwoven forming |

AYZ1218 | 1268 | 2.27 | 1700~ 1950 | >3000 | 35.0 | Pulp washing and general filtration |

ELYZ1059 | 1070 | 2.05 | 5800~ 6100 | >650 | / | For paper forming and drying |

EYZ1620 | 1650 | 2.20 | 1950~ 2200 | >2900 | 28.0 | For juice squeezing, normal sludge dewatering. |

EYZ1630 | 1600 | 2.30 | 2850~ 3400 | >3500 | 20.0 | |

EMYZ1350 | 1550 | 1.30 | 40~ 100 | >3000 | 35.0 | Fine particles press filtering. |

NON0702 | 750 | 2.20 | 50~ 300 | >900 | 38.0 | Nonwoven belt for general fine particles dewatering |

NON0902 | 900 | 2.50 | 50~ 300 | >1000 | 40.0 |