Fiber Glass Filter Fabric And Filter Bags For Dust Collection

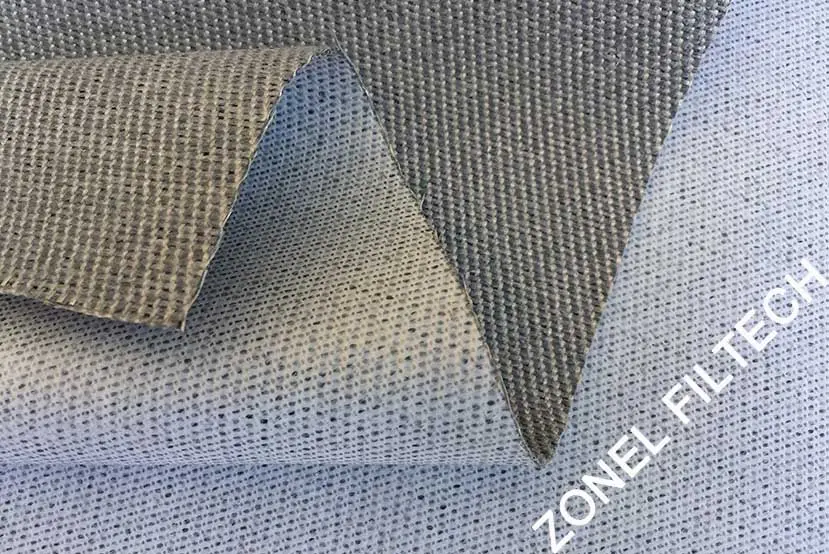

Zonel brand fiberglass filter fabrics are made of E-fiber glass filament/E-fiber glass bulked yarn with some special finish treatment after the weaving works according to the different working conditions to make the glass fiber filter cloth with a much better flexibility, abrasion resistance and also suitable to be used in some special chemical circumstances besides the high temperature so as to prolong the service life of the fiberglass dust filter bags.

Zonel Filtech provides both fiberglass filter fabric rolls and fiberglass ready-made dust filter bags, we also offer free consulting to our clients to help them get the most suitable fiberglass filter bags for their bag filter houses, as well as the relevant filter bag supporting cages for their glass fiber dust filter bags and the accessories of the purging systems, etc.

If any help is needed from Zonel Filtech, just feel free to send the inquiry! Why choose the fiberglass filter bag with PTFE membrane treatment?

Fiber glass filter fabric and filter bags for industrial dust collection

Introduction of fiber glass filter fabric and filter bag:

Zonel brand fiber glass filter fabrics are made of E-fiber glass filament/E-fiber glass bulked yarn with some special finish treatment after the weaving works according to the different working conditions to make the glass fiber filter cloth with a much better flexibility, abrasion resistance and also suitable to be used in some special chemical circumstances besides the high temperature so as to prolong the service life of the fiberglass dust filter bags.

Zonel Filtech provides both the fiber glass filter fabric rolls and ready-made fiber glass dust filter bags, we also offer free consulting to our clients to help them to get the most suitable fiber glass dust filter bags for their bag filter houses, as well as the relevant filter bag supporting cages and the accessories of the purging systems, etc.

To help our client to reduce the emission rate, we developed the low resistance & high-efficiency PTFE laminated fiber glass filter bag, the emission rate can be less than 5mg/Nm3, which keeps the perfect performance for the cement industry (Fiber glass filter bags for cement kiln exhausting dust air serial), metallurgy industry and some other high-temperature dust air purification circumstances.

Relevant products:

Fiber glass needle felt filter cloth and filter bags

The FiberGlass Filter Bags for Dust Air Filtration from Cement Kiln

Typical technical specifications of the fiber glass filter fabric from Zonel Filtech(after finish treatment)

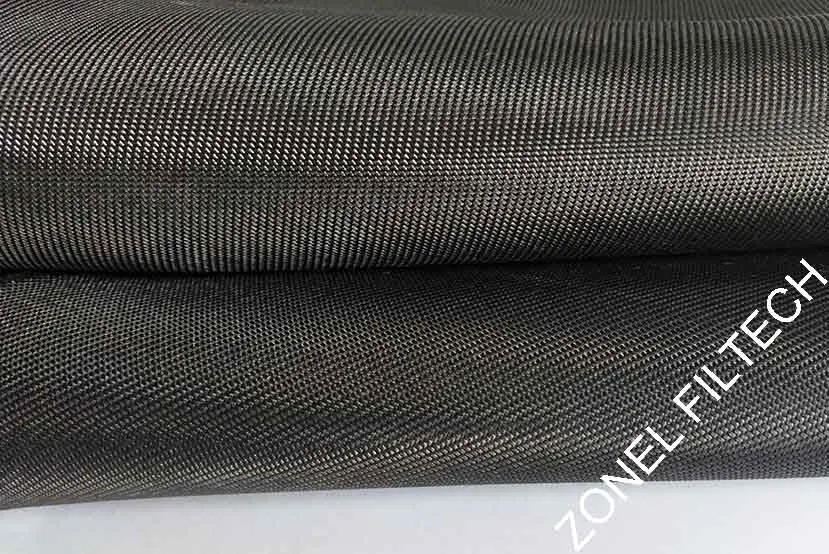

E-fiber glass filament filter fabrics

Model No. | Weight (g/m2) | Thick. (mm) | Tensile strength (N/25mm) | Bursting strength ≥N @2cm | Air permeability (dm³/m2.s) @200Pa | Temperature °C | Construction | |

Warp | Weft | |||||||

ZFE-300 | 315 | 0.3±0.03 | 1980 | 1560 | 700 | 180~320 | 280 | Twill |

ZFE-400 | 420 | 0.4±0.04 | 2080 | 1790 | 820 | 160~320 | 280 | Twill |

ZFE-500 | 540 | 0.5±0.05 | 2254 | 2205 | 940 | 180~300 | 280 | Double filling weave |

ZFE-600 | 620 | 0.6±0.06 | 2380 | 2380 | 1080 | 190~310 | 280 | Double filling weave |

ZFE-700 | 720 | 0.7±0.07 | 2460 | 2420 | 1200 | 180~300 | 280 | Double filling weave |

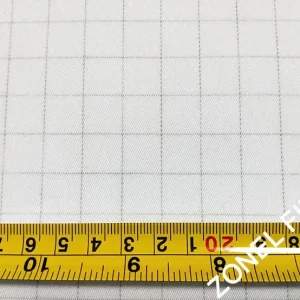

E-fiber glass filament filter fabrics with PTFE membrane treatment

Model No. | Weight (g/m2) | Thick. (mm) | Tensile strength (N/25mm) | Bursting strength ≥N @2cm | Air permeability (dm³/m2.s) @200Pa | Temperature °C | Construction | |

Warp | Weft | |||||||

ZFE-300 | 315 | 0.3±0.03 | 1980 | 1560 | 700 | 20~40 | 260 | Twill |

ZFE-400 | 420 | 0.4±0.04 | 2080 | 1790 | 820 | 20~40 | 260 | Twill |

ZFE-500 | 540 | 0.5±0.05 | 2254 | 2205 | 940 | 20~40 | 260 | Double filling weave |

ZFE-600 | 620 | 0.6±0.06 | 2380 | 2380 | 1080 | 20~40 | 260 | Double filling weave |

ZFE-700 | 720 | 0.7±0.07 | 2460 | 2420 | 1200 | 20~40 | 260 | Double filling weave |

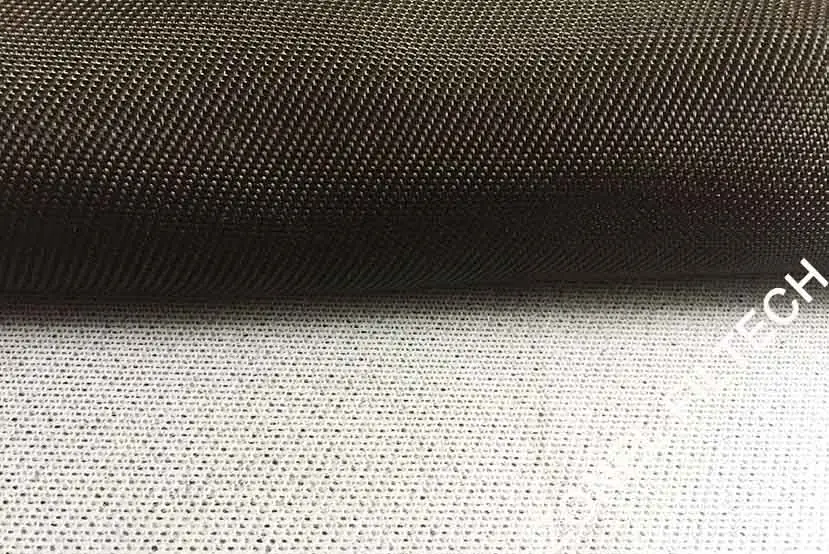

E-fiber glass filter fabric with bulked yarn

Model No. | Weight (g/m2) | Thick. (mm) | Tensile strength (N/25mm) | Bursting strength ≥N @2cm | Air permeability (dm³/m2.s) @200Pa | Temperature °C | Construction | |

Warp | Weft | |||||||

ZFE-500 | 480 | 0.5±0.05 | 1800 | 1200 | 820 | 250~360 | 280 | Twill |

ZFE-600 | 620 | 0.6±0.06 | 1920 | 1426 | 910 | 290~395 | 280 | Twill |

ZFE-700 | 720 | 0.7±0.07 | 2150 | 1620 | 1110 | 280~370 | 280 | Double filling weave |

ZFE-800 | 820 | 0.8±0.08 | 2240 | 1840 | 1200 | 260~360 | 280 | Double filling weave |

ZFE-900 | 900 | 0.9±0.09 | 2420 | 2060 | 1360 | 240~350 | 280 | Double filling weave |

E-fiber glass filter fabric with bulked yarn after PTFE membrane treatment

Model No. | Weight (g/m2) | Thickness. (mm) | Tensile strength (N/25mm) | Bursting strength ≥N @2cm | Air permeability (dm³/m2.s) @200Pa | Temperature °C | Construction | |

Warp | Weft | |||||||

ZFE-600 | 620 | 0.6±0.06 | 1920 | 1426 | 910 | 20~40/60 | 260 | Double filling weave |

ZFE-700 | 720 | 0.7±0.07 | 2150 | 1620 | 1110 | 20~40/60 | 260 | Double filling weave |

ZFE-800 | 820 | 0.8±0.08 | 2240 | 1840 | 1200 | 20~40/60 | 260 | Double filling weave |

ZFE-900 | 900 | 0.9±0.09 | 2420 | 2060 | 1360 | 20~40/60 | 260 | Double filling weave |

Properties of the fiber glass filter bags from Zonel Filtech

1. the high tensile strength:

The tensile strength of the fiber glass filter fabric is more than 4000N/50mm as usual, which is much higher than chemical fiber filter materials and the blended filter materials, that is very suitable for the long filter bags sewing.

2. Anti-corrosion:

Fiber glass filter bag can keep a good performance in the circumstance of acid and alkali (except the hydrofluoric acid and strong phosphoric acid).

3. Stable size:

Under the high temperature (280~300 degree C), the elongation of the filter bag not exceed 2%, this property means they are suitable for the long filter bags sewing, and they won’t change the shape under the high temperature(280~300 degree C).

4. After some special treatment, with a very good water and oil repellent, easy cake release.

5. Anti-hydrolysis.

6. High temperature resistance, can work continuously understand temperature of 260 degree C.

7. Great Oxidant resistant, break the limitation of the PPS fiber in some extreme circumstance (acid and alkali) but no need to concern much on the oxygen content.

8. Lower price when compare to some similar temperature-resistant chemical fiber filter materials.

9. High filter efficiency:

The fiber glass filter fabric with PTFE membrane treatment, the open size is lower than 1 micron, most of the particles only can touch with the membrane and can’t insert into the filter fabrics, not easy to be blocked and with a higher service life; at the meantime, the fiber glass with PTFE membrane treatment, the filter efficiency can up to 99.999%, can meet the strict emission requirements.

The applications of the fiber glass filter cloth and filter bags from Zonel Filtech

1. steel plants (for purifying the gas from blast furnace, arc furnaces, furnace of calcium carbide,etc.)

2. mechanical industries (for collection the fume and dust mainly from iron cupolas,etc)

3. non-ferrous metal metallurgy (for collection the fume and dust such as from the Zinc Fractionating tower, etc.)

4. cement plants (for collection of the dust from the raw mills, verticle kiln, circumgyrate kiln, white cement kiln, dryer, cement grinding mills, etc).

The fiber glass filter bags designed for cement kiln from Zonel Filtech that is made of E-fiber glass woven filter fabric with PTFE membrane laminated treatment after some special finish treatment so as to make the cement kiln dust filter bag with a much better flexibility, abrasion resistance, lower emission rate but lower resistance and very suitable to be used in the cement dust air circumstances, always can keep the perfect filtration performance and with a much longer service time.

The fiber glass dust filter bags from Zonel Filtech will accompany the full technical support to guarantee the fiber glass dust filter bags with a perfect filtration performance.

We mainly offer 2 emission rates for choice on fiber glass filter bags for the cement industry, i.e. < 20mg/Nm2, <10mg/Nm2. Only if the end users can make the maintenance on their dust collectors according to our instruction, the 3~4 years of good performance will be guaranteed.

5. Chemicals processing (for collection the dust from the dryers and micronizers in TiO2 and pigment industries, etc.)

6. Power generation and incineration industries.

Zonel

ISO9001:2015