Pulse Jet Bag Filter Housing, Dust Filter Bag Type Dust Collector

The pulse jet bag filter housing is one of the main products of Zonel Filtech, which is combined with the main filter housing (including the filter bag, filter bag supporting cage, bag tube sheet, tank and hopper, dust discharger, etc), purging system (include press air tank, airbag, pulse jet valve, blowpipe, etc), fan system (include fan with motor, silencer, etc), control system (PLC control) and so on.

Zonel Filtech can help to design bag filter housing according to the work circumstance on the client’s side, also can help them to design the layout of the suction pipe to guarantee the whole filter system will with a perfect performance.

The bag filter housing offering includes the normal bag filter housing, high-temperature bag filter housing, anti-explode bag filter housing, silo bag filter housing, etc. If any help is needed, welcome to contact Zonel Filtech!

Pulse Jet filter bag housing for dust collection

General introduction of the bag filter house

The bag house filter is nearly used in all kinds of industries to help control air pollution, according to the different purging methods, the bag filter dust collector can be divided into pulse jet bag filter housing; reverse blown dust air filter; mechanical vibrating purging dust collect, and so on!

Also according to the different dust collecting directions, the bag-type dust collector can be divided into an inner air filter system (dust is collected at the inner side of the filter bags) and an outer air filter house(dust is collected at the outer side of the filter bags); according to the chamber quantity, which also can be divided into the single chamber filter bag dust collector and multi-chambers bag house filter system; according to purging state which also can be divided into the online purging air dust filter system (the filtering is continuing when purging system activated) and offline purging air dust collectors (the filtering will be stopped when purging system activated). Different types of air dust collectors the construction always different, but no matter how, all of the air dust collectors under the same principle, i.e. block the dust particles through the filter bags before they are released into the atmosphere, how to choose a suitable air bag filter house is crucial for all of the productions.

Due to the pulse jet bag filter houses are suitable for nearly all occasions of high airflow, high moisture, high temperature, corrosive, super low emission, high filter speed and so on they can handle some very complex working circumstances, easy maintenance, and long service life, higher filter speed and lower emissions, which is one of the most popular dust filter systems for industrial application!

The pulse jet bag type dust collection system mainly combined with a dust air inlet, lower filter tank (dust air enters the dust collector and will be filtered by dust filter bags in this tank or housing), hopper, dust discharge system, and the dust can of the baghouse dust collector, upper filter tank (the filtered clean air will go out through this part of the dust collector bag house), dust collector blower/Fan (for protect the impeller of the fan, the dust collector blower always be installed at the down steam of the dust collector filter), as well as the electronic cabinet for the dust air filter system controlling, also the maintenance platform and fence, etc.

The properties of the bag filter houses

A.Can stand the higher air flow, basically, we suggested to operating at the air/cloth ratio such as 1.2m/min, but some small bag filter housing, can be operated up to 5m/min, when compare to reverse blown bag filter system with air/cloth ration only about 0.8m/min or even lower, the air filter speed for pulst jet bag type dust filter is much higher, which is helpful to reduce the dust control system investment.

B.Can be adopted to filter the dust air with higher moisture content. Due to the bag type dust control machine the filter bag is sewn or welding, without any glue inside, so even if the filter bag meet the wet circumstance, if with the good finish treatment, the physical performance nearly don’t have any change and always can help the dust filtration system keep a perfect performance.

C.Suitable for higher temperature dust removal! Through change the different materials of the filter elements, the operating temperature can be up to 280degree C.

D.Can be operated to corrosive occasions, various filter materials of the filer bags for dust collector can be chosen.

E.easy maintenance, the general maintenance and filter bags changing no need to be handled in the closed space, which is not effect the health of the operating workers.

F.lower emissions, the emission rate of pulse bag filters can be controlled less than 5mg/Nm3.

G.With the optimal designed pulse jet purging system make the clean works easy and perfect.

Applications

For dust air processing at Power plants (dust collector in thermal power plant, such as the turbine air inlet filter), metal processing (metal accessories polishing, metallurgy and son on, such as aluminum dust collector), mining, cement industries (such as special designed cement bag house or cement filters), ceramic industries, carbon black industries, pharmaceutical industries, food processing industries, chemical plants, hot air spray industries, rubber industries, battery industries, materials mixing plants, and other powder processing occasions, etc.

Zonel Filtech as one of the most professional pulse jet dust collector supplier with the modernized air filter production plant and processing machines, we can design and customize the dust collectors according to the customer requirements!

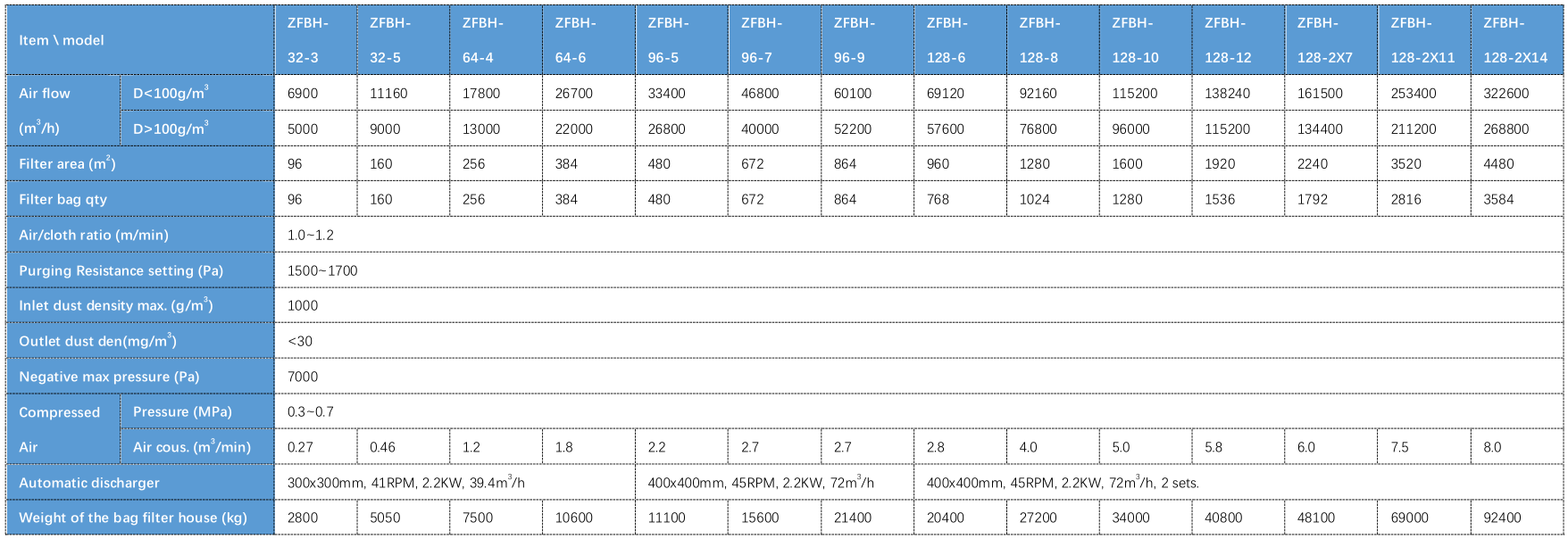

The typical parameters